Abstract

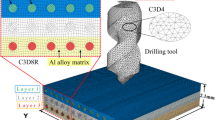

In order to improve the fatigue performance of the internal thread of the connecting rod for marine diesel engine, the internal thread cold extrusion technology is introduced into the bolt hole position. Based on the three-dimensional finite element model, the residual stress distribution around the cold extrusion internal thread of 42CrMo4 high-strength steel plate hole structure under different edge distance ratios is analyzed in detail. The multiaxial fatigue life prediction model of thread is established based on the stress-strain method; the accuracy and feasibility of the prediction model are further verified by fatigue experiments. The thread surfaces are examined by utilizing the scanning electron microscope and coordinate with the X-ray diffraction method to measure the residual stress of thread. The relationship between the residual stress distribution, surface structure, and fatigue life of the extrusion thread is revealed. The research shows that the improved fatigue prediction model gives a satisfactory accuracy in predicting the fatigue life. Both the tangential residual stress fields around the extrusion thread and the surface structure have a certain influence on its fatigue life, especially when the edge distance ratio is less than 2. The tangential residual compressive stress of the cold extrusion internal thread decreases with the edge distance ratio being smaller, while the depth of the stress zone increases firstly and then decreases. Higher load will greatly reduce the fatigue life and dispersion of the thread; the fatigue life increases linearly with the increase of the edge distance ratio under lower stress level.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Liu M, Ji ZS, Li XM (2019) Research progress of cold extrusion technology for light alloy internal thread. Mater Sci Eng 688:3. https://doi.org/10.1088/1757-899X/688/3/033029

Zheng Q, Guo Y, Wei Y (2020) Loosening of steel threaded connection subjected to axial compressive impact loading. Int J Impact Eng 144:103662. https://doi.org/10.1016/j.ijimpeng.2020.103662

Quispe J, Pasqualino IP, Estefen SF (2020) Structural behavior of threaded connections for sandwich pipes under make-up torque, external pressure, and axial load. Int J Pres Ves Pip 186. https://doi.org/10.1016/j.ijpvp.2020.104156

Fu YC, Ge ED, Su HH, Xu JH, Li RZ (2015) Cold expansion technology of connection holes in aircraft structures: a review and prospect. Chinese J Aeronaut 28:961–973. https://doi.org/10.1016/j.cja.2015.05.006

Reid L (2014) Hole cold expansion the fatigue mitigation game changer of the past 50 years. Adv Mat Res 2979:679–684. https://doi.org/10.4028/www.scientific.net/AMR.891-892.679

Chakherlou TN, Vogwell J (2004) A novel method of cold expansion which creates near uniform compressive tangential residual stress around a fastener hole. Fatigue Fract Eng Mater Struct 27:343–351. https://doi.org/10.1111/j.1460-2695.2004.00727.x

Yuan X, Yue ZF, Wen SF, Li L, Feng T (2015) Numerical and experimental investigation of the cold expansion process with split sleeve in titanium alloy TC4. Int J Fatigue 77:78–85. https://doi.org/10.1016/j.ijfatigue.2015.03.014

Liu YS, Liu YS, Shao XJ, Liu J, Yue ZF (2009) Finite element method and experimental investigation on the residual stress fields and fatigue performance of cold expansion hole. Mater Des 31:1208–1215. https://doi.org/10.1016/j.matdes.2009.09.031

Abdelghani B, Abdelkader D, Mostefa B, El HB, Abdelkrim A (2018) Numerical analysis and optimization of the residual stresses distribution induced by cold expansion technique. Frat Ed Integrita Strutt 12:252–265. https://doi.org/10.3221/IGF-ESIS.46.23

Liu J, Wu HG, Yang JJ, Yue ZF (2013) Effect of edge distance ratio on residual stresses induced by cold expansion and fatigue life of TC4 plates. Eng Fract Mech 109:130–137. https://doi.org/10.1016/j.engfracmech.2013.05.012

Li YY, Zhao SD (2011) Research on thread forming process of extrusion tapping of internal thread. Appl Mech Mater 1376:631–637. https://doi.org/10.4028/www.scientific.net/AMM.80-81.631

Li YY, Zhao SD (2011) The key technology in extrusion tapping of internal thread. Adv Mat Res 1336:2636–2641. https://doi.org/10.4028/www.scientific.net/AMR.295-297.2636

Li YY, Zhao SD (2011) Numerical analysis on the key technology in extrusion tapping of internal thread. Adv Mat Res 341-342:436–441. https://doi.org/10.4028/www.scientific.net/AMR.341-342.436

Hou HL, Zhang GP, Chen X, Zhao YQ (2020) Numerical simulation and process optimization of internal thread cold extrusion process. Mater 13:3960–3960. https://doi.org/10.3390/ma13183960

Hou HL, Zhang GP, Chen X (2022) Research on the bottom hole size of internal thread extrusion. Int J Adv Manuf Technol:1–11. https://doi.org/10.1007/s00170-022-08826-9

Zuo DW, Sun YL (2020) Semi-analytical torque modeling of Ti-6Al-4V-alloy internal trapezoidal thread extrusion forming with an emphasis on low-frequency torsional vibration. J Mater Process Technol 286:116812. https://doi.org/10.1016/j.jmatprotec.2020.116812

Hou YJ, Zuo DW, Sun YL, Wang L, Li L (2019) Distributional analysis of residual stresses with the Ti-6Al-4V internal trapezoidal thread torsional vibration extrusion. Int J Adv Manuf Technol 105:4289–4307. https://doi.org/10.1007/s00170-019-04472-w

Miao H, Mei Q, Yuan JY, Zheng ZX, Jin YF, Zuo DW (2016) Low cycle fatigue and strengthening mechanism of cold extruded large diameter internal thread of Q460 steel. CHIN J Mech Eng-En 29:556–563. https://doi.org/10.3901/CJME.2016.0318.033

Miao H, Zuo DW, Wang HJ (2010) Optimization of tap parameters for internal thread cold extrusion of high strength steel based on genetic algorithm. Key Eng Mater 426-427:537–539. https://doi.org/10.4028/www.scientific.net/KEM.431-432.434

Miao H, Zuo DW, Wang HJ (2015) Surface characteristics of internal thread during cold extrusion for Q460 high strength steel. Adv Sci Lett 3:65–74

He Q, Jiang YX, Jing XW, Jiang YG, Zhou HG, Fu BF (2022) Research and optimization of process parameters for internal thread forming based on numerical simulation and experimental analysis. Mater 15:3160–3160. https://doi.org/10.3390/ma15093160

Wan N, He Q, Jiang YX, Zhou HG, Fu BF (2023) Numerical and experimental investigation of the influence of the machining parameters on residual stress distribution of internal thread cold extrusion. CIRP J Manuf Sci Technol 40:142–154. https://doi.org/10.1016/j.cirpj.2022.10.005

Zhao CM, Hu HY, Zhou YF, Gao YK, Ren XJ, Yang QX (2013) Experimental and numerical investigation of residual stresses around cold extrusion hole of ultrahigh strength steel. Mater Des 50:78–84. https://doi.org/10.1016/j.matdes.2013.02.073

Ayatollahi MR, Arian Nik M (2009) Edge distance effects on residual stress distribution around a cold expanded hole in Al 2024 alloy. Comp Mater Sci 45:1134–1141. https://doi.org/10.1016/j.commatsci.2009.01.018

Aircraft Design Manual. Beijing, China: Aviation Industry Press; 2001.

Maddox SJ (1975) The effect of mean stress on fatigue crack propagation a literature review. Int J Fracture 11. https://doi.org/10.1007/BF00033527

Lv ZQ, Huang HZ, Wang HK, Gao HY, Zuo FJ (2016) Determining the Walker exponent and developing a modified Smith-Watson-Topper parameter model. J Mech Sci Technol 30:1129–1137. https://doi.org/10.1007/s12206-016-0217-3

Manson SS, Halford GR (1981) Practical implementation of the double linear damage rule and damage curve approach for treating cumulative fatigue damage. Int J Fracture 17:169–192. https://doi.org/10.1007/BF00053519

Peng Y, Liu Y, Li HR, Xing JK (2022) Research on low cycle fatigue life prediction considering average strain. Mater Res Express 9. https://doi.org/10.1088/2053-1591/ac4b4d

Code availability

Not applicable.

Funding

Qiang He is supported by The Chinese Postdoctoral Science Foundation (2022M712932), The Graduate Student Practice Innovation Projects in Jiangsu Province (NO. SJCX23_2144) and The Natural Science Fundamental Research Project of Jiangsu Universities (No. 22KJA460003). Honggen Zhou is supported by The National Defense Basic Scientific Research Project (No. JCKY2021414B011), The Intelligent Methanol-Fueled New Energy Ship R&D Project (Guangdong Natural Resources Cooperation [2021] No. 44), and The RO-RO Passenger Ship Efficient Construction Process and Key Technology Research (Project No. CJ07N20). The authors would like to express their thanks.

Author information

Authors and Affiliations

Contributions

Conceptualization: Honggen Zhou; resources: Yonggang Jiang; software: Nian Wan; writing—original draft: Nian Wan; writing—review and editing: Qiang He; methodology: Xuwen Jing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

All authors have read and agreed to the published version of the manuscript.

Consent for publication

All authors have read and agreed to the published version of the manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wan, N., He, Q., Jing, X. et al. Numerical and experimental investigation of the effect of cold extrusion process on residual stress and fatigue life of internal thread of high-strength steel. Int J Adv Manuf Technol 127, 4713–4726 (2023). https://doi.org/10.1007/s00170-023-11765-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11765-8