Abstract

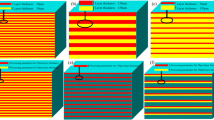

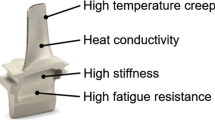

Intelligent additive manufacturing is the direction of development, and changing parameters during the manufacturing process is an effective measure to adjust the quality of the part. The purpose of this paper is to investigate the stability of single-track and multilayer fabricated Ti-6Al-4 V designed and fabricated by laser powder bed fusion with high degrees of freedom. The effects of single-track, relative density, surface quality, and microstructure and mechanical properties were investigated by designing a process strategy based on the interval powder layer thickness and regulating the process parameters. The survey shows that the point distance of less than 35 μm, the exposure time of longer than 120 μs, and the hatch spacing of greater than 70 μm can ensure the relative density of specimens with high layer thickness. The microstructure consists mainly of acicular martensite αʹ filled in columnar β grains, and acicular martensite αʹ grains are relatively sparse. The tensile strength, yield strength, and elongation of the specimens were 1109 MPa, 1053 MPa, and 5.6%, respectively. The fracture is a combination of ductile fracture and brittle fracture. The building rate was 9 mm3/s, which is higher than the results obtained in previous studies. The survey can provide theoretical support for researchers and data support for engineers.

Graphical Abstract

Similar content being viewed by others

References

Wang Z, Wang C, Li C, Qin Y, Zhong L, Chen B, Li Z, Liu H, Chang F, Wang J (2017) Analysis of factors influencing bone ingrowth into three-dimensional printed porous metal scaffolds: a review. J Alloys Compd 717:271–285. https://doi.org/10.1016/j.jallcom.2017.05.079

Xiao Z, Yang Y, Xiao R, Bai Y, Song C, Wang D (2018) Evaluation of topology-optimized lattice structures manufactured via selective laser melting. Mater Des 143:27–37. https://doi.org/10.1016/j.matdes.2018.01.023

Gu D, Wang H, Dai D, Yuan P, Meiners W, Poprawe R (2015) Rapid fabrication of Al-based bulk-form nanocomposites with novel reinforcement and enhanced performance by selective laser melting. Scr Mater 96:25–28. https://doi.org/10.1016/j.scriptamat.2014.10.011

Baitimerov R, Lykov P, Zherebtsov D, Radionova L, Shultc A, Prashanth KG (2018) Influence of powder characteristics on processability of AlSi12 alloy fabricated by selective laser melting. Materials 11(5):742. https://doi.org/10.3390/ma11050742

Gu D, Shi X, Poprawe R, Bourell D, Setchi R, Zhu J (2021) Material-structure-performance integrated laser-metal additive manufacturing. Science 372(6545):eabg1487. https://doi.org/10.1126/science.abg14

Chen D, Wang P, Pan R, Zha C, Fan J, Liang D, Zhao Y (2021) Characteristics of metal specimens formed by selective laser melting: a state-of-the-art review. J Mater Eng Perform 30(10):7073–7100. https://doi.org/10.1007/s11665-020-05323-6

Shi W, Liu Y, Shi X, Hou Y, Wang P (2018) Beam diameter dependence of performance in thick-layer and high-power selective laser melting of Ti-6Al-4V. Materials 11(7):1237. https://doi.org/10.3390/ma11071237

Simson D, Subbu SK (2022) Effect of process parameters on surface integrity of LPBF Ti6Al4V. Procedia CIRP 108:716–721

Kuo YL, Nagahari T, Kakehi K (2018) The effect of post-processes on the microstructure and creep properties of alloy718 built up by selective laser melting. Materials 11(6):996. https://doi.org/10.3390/ma11060996

Koutny D, Palousek D, Pantelejev L et al (2018) Influence of scanning strategies on processing of aluminum alloy EN AW 2618 using selective laser melting. Materials 11(2):298

Gullane A, Murray JW, Hyde CJ, Sankare S, Evirgen A, Clare AT (2021) On the use of multiple layer thicknesses within laser powder bed fusion and the effect on mechanical properties. Mater Des 212:110256. https://doi.org/10.1016/j.matdes.2021.110256

Sun J, Yang Y, Wang D (2013) Parametric optimization of selective laser melting for forming Ti6Al4V samples by Taguchi method. Opt Laser Technol 49:118–124. https://doi.org/10.1016/j.optlastec.2012.12.002

Song B, Dong S, Zhang B, Liao H, Coddet C (2012) Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater Des 35:120–125. https://doi.org/10.1016/j.matdes.2011.09.051

Sadeghi M S, Mohseni M, Etefagh A H, Khajehzadeh M (2022) The effect of process parameters and scanning strategies on surface roughness of stainless steel 316L SLM parts. Proc Inst Mech Eng Part E 09544089221138684 https://doi.org/10.1177/09544089221138684

Yadroitsev I, Yadroitsava I, Bertrand P, Smurov I (2012) Factor analysis of selective laser melting process parameters and geometrical characteristics of synthesized single tracks. Rapid Prototyp J. https://doi.org/10.1108/13552541211218117

Enneti RK, Morgan R, Atre SV (2018) Effect of process parameters on the selective laser melting (SLM) of tungsten. Int J Refract Met Hard Mater 71:315–319. https://doi.org/10.1016/j.ijrmhm.2017.11.035

Leuders S, Thöne M, Riemer A, Niendorf T, Tröster T, Richard HA, Maier HJ (2013) On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: fatigue resistance and crack growth performance. Int J Fatigue 48:300–307. https://doi.org/10.1016/j.ijfatigue.2012.11.011

Thomas M, Baxter GJ, Todd I (2016) Normalised model-based processing diagrams for additive layer manufacture of engineering alloys. Acta Mater 108:26–35. https://doi.org/10.1016/j.actamat.2016.02.025

Yasa E (2021) Selective laser melting: principles and surface quality. Addit Manuf 77–120 https://doi.org/10.1016/B978-0-12-818411-0.00017-3

Zhang Y, Liu F, Chen J, Yuan Y (2017) Effects of surface quality on corrosion resistance of 316L stainless steel parts manufactured via SLM. J Laser Appl 29(2):022306. https://doi.org/10.2351/1.4983263

Khorasani AM, Gibson I, Ghaderi AR (2018) Rheological characterization of process parameters influence on surface quality of Ti-6Al-4V parts manufactured by selective laser melting. Int J Adv Manuf Technol 97(9):3761–3775. https://doi.org/10.1007/s00170-018-2168-6

Majeed A, Lv J, Zhang Y, Muzamil M, Waqas A, Shamim K, Qureshi M E, Zafar F (2019) An investigation into the influence of processing parameters on the surface quality of AlSi10Mg parts by SLM process. 2019 16th international Bhurban conference on applied sciences and technology (IBCAST) 143–147 https://doi.org/10.1109/IBCAST.2019.8667175

Krol M, Tański T (2016) Surface quality research for selective laser melting of Ti-6Al-4V alloy. Arch Metall Mater 61(3):1291–1296. https://doi.org/10.1515/amm-2016-0213

Safdar A, He HZ, Wei LY, Snis A, Chavez de Paz LE (2012) Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp J 18(5):401–408. https://doi.org/10.1108/13552541211250391

Yadroitsev I, Smurov I (2011) Surface morphology in selective laser melting of metal powders. Phys Procedia 12:264–270. https://doi.org/10.1016/j.phpro.2011.03.034

Fotovvati B, Rauniyar S, Arnold JA, Chou K (2022) Experimental, computational, and data-driven study of the effects of selective laser melting (SLM) process parameters on single-layer surface characteristics. Int J Adv Manuf Technol 123(1–2):119–144. https://doi.org/10.1007/s00170-022-10167-6

Gong H, Rafi K, Gu H, Starr T, Stucker B (2014) Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes. Addit Manuf 1:87–98. https://doi.org/10.1016/j.addma.2014.08.002

Calignano F, Manfredi D, Ambrosio EP, Iuliano L, Fino P (2013) Influence of process parameters on surface roughness of aluminum parts produced by DMLS. Int J Adv Manuf Technol 67(9–12):2743–2751. https://doi.org/10.1007/s00170-012-4688-9

Günther J, Leuders S, Koppa P, Tröster T, Henkel S, Biermann H, Niendorf T (2018) On the effect of internal channels and surface roughness on the high-cycle fatigue performance of Ti-6Al-4V processed by SLM. Mater Des 143:1–11. https://doi.org/10.1016/j.matdes.2018.01.042

Zhang Y, Guillemot G, Bernacki M, Bellet M (2018) Macroscopic thermal finite element modeling of additive metal manufacturing by selective laser melting process. Comput Method Appl M 331:514–535. https://doi.org/10.1016/j.cma.2017.12.003

Chowdhury S, Yadaiah N, Prakash C, Ramakrishna S, Dixit S, Gupta LR, Buddhi D (2022) Laser powder bed fusion: a state-of-the-art review of the technology, materials, properties & defects, and numerical modelling. J Mater Res Technol 20:2109–2172. https://doi.org/10.1007/s00170-017-1287-9

Fotovvati B, Balasubramanian M, Asadi E (2020) Modeling and optimization approaches of laser-based powder-bed fusion process for Ti-6Al-4V alloy. Coatings 10(11):1104. https://doi.org/10.3390/coatings10111104

Gusarov AV, Grigoriev SN, Volosova MA, Melnik YA, Laskin A, Kotoban DV, Okunkova AA (2018) On productivity of laser additive manufacturing. J Mater Process Technol 261:213–232. https://doi.org/10.1016/j.jmatprotec.2018.05.033

Vastola G, Zhang G, Pei QX, Zhang YW (2015) Modeling and control of remelting in high-energy beam additive manufacturing. Addit Manuf 7:57–63. https://doi.org/10.1016/j.addma.2014.12.004

Ma M, Wang Z, Gao M, Zeng X (2015) Layer thickness dependence of performance in high-power selective laser melting of 1Cr18Ni9Ti stainless steel. J Mater Process Technol 215:142–150. https://doi.org/10.1016/j.jmatprotec.2014.07.034

Wang S, Liu Y, Shi W, Qi B, Yang J, Zhang F, Han D, Ma Y (2017) Research on high layer thickness fabricated of 316L by selective laser melting. Materials 10(9):1055. https://doi.org/10.3390/ma10091055

Liu Y, Zhang M, Shi W, Ma Y, Yang J (2021) Study on performance optimization of 316L stainless steel parts by high-efficiency selective laser melting. Opt Laser Technol 138:106872. https://doi.org/10.1016/j.optlastec.2020.106872

Shi X, Ma S, Liu C, Chen C, Wu Q, Chen X, Lu J (2016) Performance of high layer thickness in selective laser melting of Ti6Al4V. Materials 9(12):975. https://doi.org/10.3390/ma9120975

Qiu C, Panwisawas C, Ward M, Basoalto HC, Brooks JW, Attallah MM (2015) On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater 96:72–79. https://doi.org/10.1016/j.actamat.2015.06.004

Sufiiarov VS, Popovich AA, Borisov EV, Polozov IA, Masaylo DV, Orlov AV (2017) The effect of layer thickness at selective laser melting. Procedia Eng 174:126–134. https://doi.org/10.1016/j.proeng.2017.01.179

Vaithilingam J, Kilsby S, Goodridge RD, Christie SDR, Edmondson S, Hague RJM (2015) Functionalisation of Ti6Al4V components fabricated using selective laser melting with a bioactive compound. Mater Sci Eng C 46:52–61. https://doi.org/10.1016/j.msec.2014.10.015

Dursun G, Orhangul A, Urkmez A, Akbulut G (2022) Understanding the parameter effects on densification and single track formation of laser powder bed fusion Inconel 939. Procedia CIRP 108:258–263. https://doi.org/10.1016/j.procir.2022.03.045

Shi W, Wang P, Liu Y, Hou Y, Han G (2020) Properties of 316L formed by a 400 W power laser selective laser melting with 250μm layer thickness. Powder Technol 360:151–164. https://doi.org/10.1016/j.powtec.2019.09.059

Wang D, Wu S, Fu F, Mai S, Yang Y, Liu Y, Song C (2017) Mechanisms and characteristics of spatter generation in SLM processing and its effect on the properties. Mater Des 117:121–130. https://doi.org/10.1016/j.matdes.2016.12.060

Han X, Zhu H, Nie X, Wang G, Zeng X (2018) Investigation on selective laser melting AlSi10Mg cellular lattice strut: molten pool morphology, surface roughness and dimensional accuracy. Materials 11(3):392. https://doi.org/10.3390/ma11030392

Guan K, Wang Z, Gao M, Li X, Zeng X (2013) Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Mater Des 50:581–586. https://doi.org/10.1016/j.matdes.2013.03.056

Xiao Z, Chen C, Hu Z, Zhu H, Zeng X (2020) Effect of rescanning cycles on the characteristics of selective laser melting of Ti6Al4V. Opt Laser Technol 122:105890. https://doi.org/10.1016/j.optlastec.2019.105890

Shi W, Wang P, Liu Y, Han G (2019) Experiment of process strategy of selective laser melting forming metal nonhorizontal overhanging structure. Metals 9(4):385. https://doi.org/10.3390/met9040385

Wei K, Lv M, Zeng X, Xiao Z, Huang G, Liu M, Deng J (2019) Effect of laser remelting on deposition quality, residual stress, microstructure, and mechanical property of selective laser melting processed Ti-5Al-2.5Sn alloy. Mater Charact 150:67–77. https://doi.org/10.1016/j.matchar.2019.02.010

Kelly CN, Evans NT, Irvin CW, Chapman SC, Gall K, Safranski DL (2019) The effect of surface topography and porosity on the tensile fatigue of 3D printed Ti-6Al-4V fabricated by selective laser melting. Mater Sci Eng, C 98:726–736. https://doi.org/10.1016/j.msec.2019.01.024

Etesami SA, Fotovvati B, Asadi E (2022) Heat treatment of Ti-6Al-4V alloy manufactured by laser-based powder-bed fusion: process, microstructures, and mechanical properties correlations. J Alloys Compd 895:162618. https://doi.org/10.1016/j.jallcom.2021.162618

Sun QD, Sun J, Guo K, Waqar S, Liu JW, Wang LS (2022) Influences of processing parameters and heat treatment on microstructure and mechanical behavior of Ti-6Al-4V fabricated using selective laser melting. Adv Manuf 10(4):520–540. https://doi.org/10.1007/s40436-022-00389-y

Zhao R, Chen C, Wang W, Cao T, Shuai S, Xu S, Hu T, Liao H, Wang J, Ren Z (2022) On the role of volumetric energy density in the microstructure and mechanical properties of laser powder bed fusion Ti-6Al-4V alloy. Addit Manuf 51:102605. https://doi.org/10.1016/j.addma.2022.102605

Xu W, Lui EW, Pateras A, Qian M, Brandt M (2017) In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater 125:390–400. https://doi.org/10.1016/j.actamat.2016.12.027

Liu J, Li G, Sun Q, Li H, Sun J, Wang X (2022) Understanding the effect of scanning strategies on the microstructure and crystallographic texture of Ti-6Al-4V alloy manufactured by laser powder bed fusion. J Mater Process Technol 299:117366. https://doi.org/10.1016/j.jmatprotec.2021.117366

Su J, Xie H, Tan C, Xu Z, Liu J, Jiang F, Tang J, Fu D, Zhang H, Teng J (2022) Microstructural characteristics and tribological behavior of an additively manufactured Ti-6Al-4V alloy under direct aging and solution-aging treatments. Acta Mater 175:107763. https://doi.org/10.1016/j.triboint.2022.107763

ASTM (2014) Standard Specification for Titanium-6Aluminum-4Vanadium Alloy Castings for Surgical Implants (UNS R56406): F1108–14, ASTM International, West Conshohocken

ASTM (2014) Standard Specification for Wrought Titanium-6Aluminum-4Vanadium Alloy for Surgical Implant Applications (UNS R56400): F1472–14, ASTM International, West Conshohocken.

Cain V, Thijs L, Humbeeck JV, Hooreweder BV, Knutsen R (2015) Crack propagation and fracture toughness of Ti6Al4V alloy produced by selective laser melting. Addit Manuf 5:68–76. https://doi.org/10.1016/j.addma.2014.12.006

Simonelli M, Tsey Y, Tuck C (2014) Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti-6Al-4V. Mater Sci Eng A 616:1–11. https://doi.org/10.1016/j.msea.2014.07.086

Vrancken B, Thijs L, Kruth JP, Humbeeck JV (2012) Heat treatment of Ti6Al4V produced by selective laser melting: microstructure and mechanical properties. J Alloy Compd 541:177–185. https://doi.org/10.1016/j.jallcom.2012.07.022

Wycisk E, Siddique S, Herzog D, Walther F, Emmelmann C (2015) Fatigue performance of laser additive manufactured Ti–6Al–4V in very high cycle fatigue regime up to 109 cycles. Front Mater 2:72. https://doi.org/10.1016/j.phpro.2011.03.046

Simonelli M, Tse Y Y, Tuck C (2012) Further understanding on Ti-6Al-4V selective laser melting using texture analysis. 2012 International Solid Freeform Fabrication Symposium. University of Texas at Austin https://doi.org/10.26153/tsw/15367

Thijs L, Verhaeghe F, Craeghs T, Humbeeck JV, Kruth JP (2010) A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater 58(9):3303–3312. https://doi.org/10.1016/j.actamat.2010.02.004

Maskery I, Aremu AO, Simonelli M, Tuck C, Wildman RD, Ashcroft IA, Hague RJM (2015) Mechanical properties of Ti-6Al-4V selectively laser melted parts with body-centred-cubic lattices of varying cell size. Exp Mech 55(7):1261–1272

Funding

This research was funded by the National Natural Science Foundation of China, grant number 51875005.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Peng Wang: conceptualization, methodology, resources, funding acquisition, writing—review and editing. Dongju Chen: investigation, validation, visualization, writing—original draft. Yuhang Tang: conceptualization, review and editing. Jinwei Fan: methodology, software, visualization, writing—review and editing. Gang Li: formal analysis, investigation, data curation. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, P., Chen, D., Tang, Y. et al. The effect of process parameters on the stability and efficiency in the laser powder bed fusion of Ti-6Al-4 V based on the interval powder layer thickness. Int J Adv Manuf Technol 127, 3537–3556 (2023). https://doi.org/10.1007/s00170-023-11704-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11704-7