Abstract

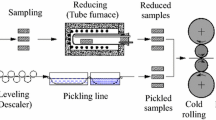

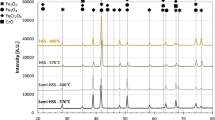

The leading quality indicators of cold-rolled strip products include surface roughness and surface finish. The present study investigates the effects of the reduction ratio and lubrication condition (dry or lubricated) on the surface roughness and surface gloss of S304 stainless steel strips and titanium grade 1 strips processed at room temperature with a rolling speed of 0.33 m/s. The results show that for both materials, the contact ratio between the workpiece and the roller increases with an increasing reduction ratio and gives rise to a higher surface gloss. Moreover, the surface gloss obtained under dry conditions is higher than that obtained under lubricated conditions. The peak cross-sectional and pit cross-sectional areas for both materials decrease as the reduction ratio increases. The corresponding improvement in the surface gloss is particularly apparent under dry conditions due to the absence of oil in the oil pits on the rolled surface. The titanium workpiece has a low yield strength of 170 MPa, and hence a high surface gloss can be obtained under a relatively low reduction ratio of 7%. By contrast, the S304 workpiece has a high yield strength of 215 MPa. As a result, a reduction ratio of at least 17.7% is required to flatten the oil pits and obtain a better surface finish. This study identifies the critical operating parameters of cold rolling affecting surface roughness and glossiness and provides insights into enhancing surface finish. Furthermore, it pinpoints that the valley cross-section area is a critical factor in determining the gloss of a surface with noticeable defects.

Similar content being viewed by others

References

Xie H, Manabe K, Tada K, Jiang Z (2016) Lubrication Characterisation Analysis of Stainless Steel Foil During Micro Rolling. Int J Adv Manuf Technol 82:65–73. https://doi.org/10.1007/s00170-015-7344-3

Kenmochi K, Yarita I, Abe H, Kobori K (1997) Flattening of Grooves Formed of Intergranular Corrosion for Austenic Stainless Steel Strip in Cold Rolling. Tetsu to Hagane 83(8):13–17. https://doi.org/10.2355/tetsutohagane1955.83.8_485

Ahmed R, Sutcliffe MPF (2000) Identification of Surface Features on Cold-rolled Stainless Steel Strip. Wear 244:60–70. https://doi.org/10.1016/S0043-1648(00)00442-7

Kenmochi K, Yarita I, Abe H, Fukuhara A, Komatu T, Kaito H (1997) Effect of Micro-defects on the Surface Gloss of Cold-rolled Stainless-Steel Strip. J Mater Process Technol 69(1-3):106–111. https://doi.org/10.1016/S0924-0136(97)00003-4

Yamamoto H, Ikuta H, Shoji F (2007) Surface Characteristics of Stainless Steel Sheets Cold-rolled with Rolls Polished in Axial and Other Directions. Tetsu to Hagane 93(11):687–692. https://doi.org/10.2355/tetsutohagane.93.687

Todorovic P, Tadic B, Vukelic D, Jeremic M, Randjelovic S, Nikolic R (2015) Analysis of the Influence of Loading and the Plasticity Index on Variations in Surface Roughness between Two Flat Surfaces. Tribol Int 81:276–282. https://doi.org/10.1016/j.triboint.2014.09.012

Sutcliffe MPF, Georgiades F (2002) Characterisation of Pit Geometry in Cold-rolled Stainless Steel Strip. Wear 253:963–974. https://doi.org/10.1016/S0043-1648(02)00247-8

Jeng Y-R, Lee J-T, Hwu Y-J, Liu L-C, Chun-Yi L (2020) Effects of Operation Parameters of Cold Rolling on Surface Finish of Aluminum. Tribol Int 148:106321. https://doi.org/10.1016/j.triboint.2020.106321

Chang D-F, Marsault N, Wilson WRD (2008) Lubrication of Strip Rolling in the Low-Speed Mixed Regime. Tribol Trans 39:407–415. https://doi.org/10.1080/10402009608983546

Jeng Y-R (2008) Impact of Plateaued Surfaces on Tribological Performance. Tribol Trans 39:354–361. https://doi.org/10.1080/10402009608983538

Qiu ZL, Yuen WYD, Tieu AK (1999) Mixed-Film Lubrication Theory and Tension Effects on Metal Rolling Processes. J Tribol 121:908–915. https://doi.org/10.1115/1.2834154

Lin H-S, Marsault N, Wilson WRD (1998) A Mixed Lubrication Model for Cold Strip Rolling—-Part I: Theoretical. Tribol Trans 41:317–326. https://doi.org/10.1080/10402009808983754

Kuo F, Zang Y (2014) Partial Film Lubrication Characteristics of Inlet Zone in Cold Strip Rolling. J Tribol 136:041502. https://doi.org/10.1115/1.4027858

Xing L, Sun J, Wei Z, Li G, Zhang D (2021) Effect of Minimum Friction Coefficient on Vibration Stability in Cold Rolling Mill. Tribol Int 159:106958. https://doi.org/10.1016/j.triboint.2021.106958

Chang L, Jeng Y-R, Qingtao Y (2017) Analysis of Thermal Stability of High-Performance Rolling/Sliding Contacts in Mixed Lubrication. Tribol Trans 60(6):1120–1128. https://doi.org/10.1080/10402004.2016.1262088

Wu C, Zhang L, Qu P, Li S, Jiang Z (2022) HD-lubricated High-speed Small Reduction Rolling of Hard Steel Strips with Elastically Deformable Work Rolls. Tribol Int 165:107295. https://doi.org/10.1016/j.triboint.2021.107295

Chang L, Jeng Y-R, Huang PY (2013) Modeling and analysis of the meshing losses of involute spur gears in high-speed and high-load conditions. Journal Tribol 135(1). https://doi.org/10.1115/1.4007809

Mekicha MA, de Rooij MB, Jacobs L, Matthews DTA, Schipper DJ (2021) Understanding the Generation of Wear Particles in Cold Rolling Processes. Tribol Int 155:106789. https://doi.org/10.1016/j.triboint.2020.106789

Jacobs LJM, vanDam KNH, Wentink DJ, deRooij MB, van derLugt J, Schipper DJ, Hoefnagels JPM (2022) Effect of Asymmetric Material Entrance on Lubrication in Cold Rolling. Tribol Int 175:107810. https://doi.org/10.1016/j.triboint.2022.107810

Schmid SR, Wilson WRD (1995) Lubrication of Aluminum Rolling by Oil-in-Water Emulsions. Tribol Trans 38:452–458. https://doi.org/10.1080/10402009508983428

Zhou G, Li H, He A, Liu C, Sun W, Liu Z, Han C (2022) Simulation and Control of High-order Flatness Defect in Rolling Wide Titanium Strip with 20-high Mill. Int J Adv Manuf 120:5483–5496. https://doi.org/10.21203/rs.3.rs-155420/v1

Ahmed R, Sutcliffe MPF (2001) An Experimental Investigation of Surface Pit Evolution During Cold-Rolling or Drawing of Stainless Steel Strip. J Tribol 123:1–7. https://doi.org/10.1115/1.1327580

Mancini E, Campana F, Sasso M, Newaz G (2012) Effects of Cold Rolling Process Variables on Final Surface Quality of Stainless Steel Thin Strip. Int J Adv Manuf Technol 61:63–72. https://doi.org/10.1007/s00170-011-3698-3

Mancini E, Sasso M, Amodio D, Ferretti R, Sanfilippo F (2012) Surface Defect Generation and Recovery in Cold Rolling of Stainless Steel Strips. J Tribol 133:012202. https://doi.org/10.1115/1.4002218

Jywe W-Y, Jeng Y-R, Liu C-H, Teng Y-F, Wu CH, Wang HS, Chen Y-J (2008) A novel 5DOF thin coplanar nanometer-scale stage. Precis Eng 32(4):239–250. https://doi.org/10.1016/j.precisioneng.2007.11.001

Bitelli G, Simone A, Girardi F, Lantieri C (2012) Laser Scanning on Road Pavements: A New Approach for Characterizing Surface Texture. Sensors 12(7):9110–9128. https://doi.org/10.3390/s120709110

Whitehouse DJ, Bowen DK, Venkatesh VC, Lonardo P, Brown CA (1994) Gloss and Surface Topography. CIRP Ann Manuf Technol 43(2):541–549. https://doi.org/10.1016/S0007-8506(07)60500-9

Funding

The China Steel Corporation, Taiwan, financially supported this work.

Author information

Authors and Affiliations

Contributions

Yeau-Ren Jeng: Conceptualization, Supervision, Writing – original draft, Writing – review & editing. Jong-Ning Aoh: Supervision, Writing – review & editing. Jian-Ting Lee: Methodology, Software, Data curation, Writing – original draft, Writing – review & editing. Lee-Cheng Liu: Validation, Resources, Ping-Chi Tsai: Writing – review & editing. Pay-Yau Huang: Writing – review & editing.

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jeng, YR., Aoh, JN., Lee, JT. et al. Effects of cold-rolling operation parameters on the surface quality of stainless steel and titanium strips with oil pits. Int J Adv Manuf Technol 127, 1811–1821 (2023). https://doi.org/10.1007/s00170-023-11685-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11685-7