Abstract

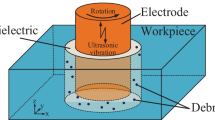

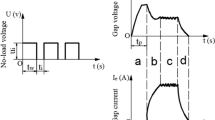

Ultrasonic vibration–assisted electrical discharge machining (UEDM) was studied to improve the machining performance for TC4 micro-holes. First, a computational fluid dynamic (CFD) model of inter-electrode gap for the micro-hole was established using COMSOL Multiphysics, and the effect of ultrasonic amplitude on the distribution of fluid and debris in the inter-electrode gap was analyzed. The experimental study of UEDM for machining performance of TC4 micro-hole under different machining parameters was conducted by using the controlled variable method. Results showed that the ultrasonic vibration of the electrode is beneficial to improve the machining performance for micro-hole. Under the optimal processing parameters, the material removal rate is improved four times, and RTWR and θ are reduced by about 50%. Finally, the neural network and genetic algorithm were used to predict and optimize the experimental results. The average error is 4.1% between the optimal processing parameters [Xn] obtained by the above method and from the experiment.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Rajhi W, Alatawi I, Subhani T, Ayadi B, Al-Ghamdi A, Khaliq A (2021) A contribution to numerical prediction of surface damage and residual stresses on die-sinking EDM of Ti6Al4V. J Manuf Process 68:1458–1484. https://doi.org/10.1016/j.jmapro.2021.06.056

Wang Y, Zhao W, Wu Y, Gang L, Wu X (2018) Micro/nano-structures transition and electrochemical response of ti-6al-4v alloy in simulated seawater. Surf Topogr 6(3):034009. https://doi.org/10.1088/2051-672X/aac785

Xuanyu M, Sergio A, John M, Songlin D (2022) The state of the art of electrical discharge drilling: a review. J. Adv. Manuf. Technol 121(5–6):2947–2969. https://doi.org/10.1007/s00170-022-09549-7

Sivakumar K, Kumar JVSP, Sai Prasanna Kuma, J, Loganathan K, Mugendiran V, Maridurai T, Suresh K (2022) Machining characteristics of silane-treated wheat husk biosilica in deionized water dielectric on EDM drilling of Ti-6Al-4 V alloy. Biomass Conv. Bioref https://doi.org/10.1007/s13399-022-02308-4

Zhao WS, Wang ZL, Di SC (2002) Ultrasonic and electric discharge machining to deep and small hole on titanium alloy. J Manuf Process 120(1–3):101-106–101-106. https://doi.org/10.1016/S0924-0136(01)01149-9

Li Z, Bai J (2018) Influence of alternating side gap on micro-hole machining performances in micro-EDM. J Adv Manuf Technol 94(1–4):979–989. https://doi.org/10.1007/s00170-017-0959-9

Plaza S, Sanchez JA, Perez E, Gil R, Bet I, Ortega N, Pombo I (2014) Experimental study on micro EDM-drilling of Ti6Al4V using helical electrode. Precis Eng 38(4):821–7. https://doi.org/10.1016/j.precisioneng.2014.04.010

Ferraris E, Castiglioni V, Ceyssens F, Corda M, Reynaerts D (2012) Micro EDM deep drilling with insulated tool electrodes [C]. International Conference on Multi Material Micro Manufacturing 93–96. https://doi.org/10.3850/978-981-07-3353-7_318

Ferraris E, Castiglioni V, Ceyssens F, Annoni M, Lauwers B, Reynaerts D (2013) EDM drilling of ultra-high aspect ratio micro holes with insulated tools. CIRP Ann Manuf Technol 62(1):191–194. https://doi.org/10.1016/j.cirp.2013.03.115

Sabyrov N, Jahan MP, Bilal A, Perveen A (2019) Ultrasonic vibration assisted electro-discharge machining (EDM)–an overview. Materials 12(3):522–577. https://doi.org/10.3390/ma12030522

Yu ZY, Zhang Y, Li J, Luan J, Zhao F, Guo D (2009) High aspect ratio micro-hole drilling aided with ultrasonic vibration and planetary movement of electrode by micro-EDM. CIRP Ann Manuf Technol 58(1):213–216. https://doi.org/10.1016/j.cirp.2009.03.111

Goiogana M, Sarasua JA, Ramos JM (2018) Ultrasonic assisted electrical discharge machining for high aspect ratio blind holes. Procedia CIRP 68:81–85. https://doi.org/10.1016/j.procir.2017.12.026

Li ZK, Tang J, Bai JC (2020) A novel micro-EDM method to improve microhole machining performances using ultrasonic circular vibration (UCV) electrode. Int. J. Mech. Sci 175:105574. https://doi.org/10.1016/j.ijmecsci.2020.105574

Xing Q, Yao Z, Zhang Q (2021) Effects of processing parameters on processing performances of ultrasonic vibration-assisted micro-EDM. J Adv Manuf Technol 112:71–86. https://doi.org/10.1007/s00170-020-06357-9

Mastud S, Kothari NS, Singh RK, Joshi SS (2015) Modeling debris motion in vibration-assisted reverse micro electrical discharge machining process (R-MEDM). J Microelectromech Sys 24(3):661–676. https://doi.org/10.1109/JMEMS.2014.2343227

Li G, Natsu W, Yu Z (2018) Study on debris behavior and its influence on EDM characteristics in deep micro-hole machining. Procedia CIRP 68:578–581. https://doi.org/10.1016/j.procir.2017.12.117

Li G, Natsu W, Yu Z (2019) Study on quantitative estimation of bubble behavior in micro hole drilling with EDM. Int. J. Mach. Tools Manuf 146:103437. https://doi.org/10.1016/j.ijmachtools

Liew PJ, Yan J, Kuriyagawa T (2014) Fabrication of deep micro-holes in reaction-bonded SiC by ultrasonic cavitation assisted micro-EDM. Int J Mach Tools Manuf 76(1):13–20. https://doi.org/10.1016/j.ijmachtools.2013.09.010

Dong Y, Li G, Wang Y, Song JB, Yang S, Yu HY (2021) Study on the effective discharge energy mechanism of vertical ultrasonic vibration-assisted EDM processing. P I Mech Eng B-J Eng 236(4):453–461. https://doi.org/10.1177/09544054211028527

Cao FG (2014) Electro-discharge machining. Chemical Industry Press, Beijing, China

Funding

The authors received financial support for this work from the National Natural Science Foundation of China (grant no. 51905363), the Natural Science Foundation of Jiangsu Province (grant no. BK20190940), and the China Postdoctoral Science Foundation (grant no. 2019M661914).

Author information

Authors and Affiliations

Contributions

Peng Zhang: data curation, investigation, writing—original draft, writing—review and editing. Zhen Yin, Daguo Yu, Xingquan Shen, and Yanqing Wang: funding acquisition, methodology, project administration, supervision. Chenwei Dai and Kun Zhang: validation.

Corresponding author

Ethics declarations

Consent to participate

It is confirmed that all the authors are aware and satisfied of the authorship order and correspondence of the paper.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, P., Yin, Z., Yu, D. et al. Experimental research and multi-objective optimization of ultrasonic vibration–assisted EDM for Ti6Al4V micro-holes. Int J Adv Manuf Technol 127, 3413–3425 (2023). https://doi.org/10.1007/s00170-023-11641-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11641-5