Abstract

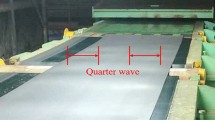

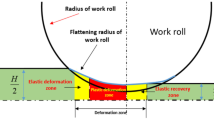

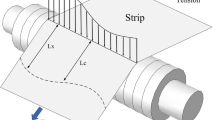

The high-order flatness defect of DP980 dual phase steel in the tandem cold rolling process has a great influence on the stability of strip production and the stable production of the following process. In this paper, a multipass simulation model based on ABAQUS was used to study the bending force of the S1 to S4 stands on the strip elongation deviation of DP980 in the process of cold rolling. The simulation results show that the work roll bending force (WRB) and the intermediate roll bending force (IRB) have different effects on strip elongation deviation. After fitting the regulation curve of the strip profile with the sixth-order polynomial and tenth-order polynomial, a bending force linear combination control strategy was established, which could only control the thickness of the quarter-wave defect position. The experimental results show that this strategy can reduce quarter-wave flatness defects from 18.22 to 10.87 IU.

Similar content being viewed by others

Data availability

The authors confirm that the data and material supporting the findings of this work are available within the article.

Code availability

Not applicable.

References

Linghu KZ, Jiang ZY, Li F, Zhao JW, Yu M, Wang YQ (2014) FEM analysis of profile control capability during rolling in a 6-high CVC cold rolling mill. In Advanced Materials Research[C]. Trans Tech Publications Ltd. 988:257–262. https://doi.org/10.4028/www.scientific.net/AMR.988.257

Moazeni B, Salimi M (2015) Investigations on relations between shape defects and thickness profile variations in thin flat rolling[J]. Int J Adv Manuf Technol 77(5):1315–1331. https://doi.org/10.1007/s00170-014-6544-6

Li LJ, Xie HB, Liu TW, Li XS, Li X, Huo MS, Wang ER, Li JX, Liu HQ, Sun L, Jiang ZY (2022) Effects of rolling force on strip shape during tandem cold rolling using a novel multistand finite element model [J]. Steel Res Int 93(2):2100359. https://doi.org/10.1002/srin.202100359

Zhou GY, He AR, Liu C, Zhou MW, Qin J, Liu ZQ (2020) Modeling modellingmodeling and simulationsimulation of wide commercial pure titanium strip rolling on Sendzimir 20-high Mill [J]. Rare Metal Mater Eng 49(07):2333–2339

Xie L, He AR, Liu C (2018) A rapid calculation method for predicting roll deformation of six-high rolling mill[J]. J Iron Steel Res Int 25(9):901–909. https://doi.org/10.1007/s42243-018-0131-2

Lee SH, Song GH, Lee SJ, Kim BM (2011) Study on the improved accuracy of strip profile using numerical formula model in continuous cold rolling with 6-high mill[J]. J Mech Sci Technol 25(8):2101–2109. https://doi.org/10.1007/s12206-011-0605-7

Feng XW, Wang XC, Sun JQ, Yang Q (2019) Analysis of tapered work roll shifting technique in 5-stand UCMW tandem cold rolling process[J]. Aust J Mech Eng 2019:1–9. https://doi.org/10.1080/14484846.2019.1606762

Nam SY, Zamanian A, Shin TJ, Hwang SM (2020) A novel on-line model for the prediction of strip profile in cold rolling[J]. ISIJ Int 60(2):308–317. https://doi.org/10.2355/isijinternational. (ISIJINT-2019-233)

Chen ZY, Liu Y, Valera-Medina A, Robinson F, Michael P (2021) Multi-faceted modelling for strip breakage in cold rolling using machine learning[J]. Int J Prod Res 59(21):6347–6360. https://doi.org/10.1080/00207543.2020.1812753

Deng J, Sun J, Peng W, Zhang DH (2019) Application of neural networks for predicting hot-rolled strip crown[J]. Appl Soft Comput 78:119–131. https://doi.org/10.1016/j.asoc.2019.02.030

Wang Y, Li CS, Peng LG, An RD, Jin X (2021) Application of convolutional neural networks for prediction of strip flatness in tandem cold rolling process[J]. J Manuf Proc 68:512–522. https://doi.org/10.1016/j.jmapro.2021.05.062. (Technology, 90(9-12), 2723-2731)

Jin X, Li CS, Wang Y, Li XG, Gu T, Xiang YG (2020) Multi-objective optimization of intermediate roll profile for a 6-high cold rolling mill. Metals 10(2):287. https://doi.org/10.3390/met10020287

Wang XC, Yang Q, Sun YZ (2014) Shape control strategy by bending force combination adjustment for 6-hi cold rolling mill [J]. Chi J Eng 36(6):824–829. https://doi.org/10.13374/j.issn1001-053x.2014.06.017

Zhang Y, Yang Q, Wang XC (2011) Control strategies of asymmetric strip shape in six-high cold rolling mill[J]. J Iron Steel Res 18(9):6. https://doi.org/10.1016/S1006-706X(12)60030-2

Wang QL, Sun J, Liu YM, Wang PF, Zhang DH (2017) Analysis of symmetrical flatness actuator efficiencies for UCM cold rolling mill by 3D elastic–plastic FEM[J]. Int J Adv Manuf Technol 92(1–4):1371–1389. https://doi.org/10.1007/s00170-017-0204-6

Shao J, Yao CH, He AR, Yang Q, Sun WQ, Xu L (2015) Subsection cooling setup and application in ultra wide hot-rolled aluminum strips based on multiple prediction[J]. Chin J Eng 37(S2):148–154

Ding ZY, Wei B, Xie JZ (2009) Application of roll stepped cooling technology for sheet shape control in Angang 1450 mm continuous cold roliing mills[J]. Angang Technol 3:5(58–62). https://doi.org/10.3969/j.issn.1006-4613.2009.03.013

Ma X, Wang D, Liu H (2017) Coupling mechanism of control on strip profile and flatness in single stand universal crown reversible rolling mill[J]. Steel Res Int 88(9):1600495. https://doi.org/10.1002/srin.201600495

Yuan ZW, Xiao H (2015) Plate shape control theory and experiment for 20-high mill[J]. J Iron Steel Res Int 22(11):996–1001. https://doi.org/10.1016/S1006-706X(15)30102-3

Li H, Yao C, Shao J, He AR, Zhou Z, Li W (2020) Prediction and control technology of stainless steel quarter buckle in hot rolling[J]. Metals 10(8):1060. https://doi.org/10.3390/met10081060

Chen LZ, Sun WQ, He AR, Liu C, Qiang Y (2022) Study on quarter-wave generation mechanism in DP980 steel during cold rolling[J]. Int J Adv Manuf Technol 120(1):313–327. https://doi.org/10.1007/s00170-021-08395-3

Funding

This work was financially supported by the National Natural Science Foundation of China (Grant No. 52004029) and Fundamental Research Funds for the Central Universities (FRF-TT-20–06).

Author information

Authors and Affiliations

Contributions

Wenquan Sun provided the simulation data, organized the experiment, and completed the draft; Luzhen Chen analyzed the simulation data; Anrui He instructed the revision of the draft; Chao Liu helped to verify the accuracy of the FEM; Yi Qiang provided constructive suggestions on experiments; and Tieheng Yuan helped collect data in production enterprises.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

This work is approved by all authors for publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, W., Chen, L., He, A. et al. Study on quarter-wave control of DP980 steel based on a bending force linear combination strategy. Int J Adv Manuf Technol 127, 2881–2892 (2023). https://doi.org/10.1007/s00170-023-11637-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11637-1