Abstract

Precision bearings are key components of mechanical equipment, and their quality almost restricts the overall development level of key technologies in the equipment manufacturing industry. As the critical element of precision bearings, the surface quality of rollers significantly affects their operational performance, reliability, and fatigue life. The development of surface finishing technology for rollers is a practical solution to improve their surface quality. However, there is a lack of systematic exposition of the research status and development direction of this technology. This study provides a comprehensive review and summary of the existing surface finishing technology for cylindrical rollers. First, the article introduces the impact of surface integrity on bearing performance. Second, it provides a comprehensive classification and summary of the current surface finishing technologies for cylindrical rollers, which include centerless grinding, superfinishing, electrochemical mechanical finishing, magnetic fluid grinding, double-side lapping, double-disc straight groove grinding, shear thickening polishing, and mass finishing. Third, the surface roughness and roundness error ranges achieved by different finishing technologies are quantitatively compared, and their processing characteristics are comprehensive compared. Finally, the article forecasts the future development trend of surface finishing technology for cylindrical rollers.

Similar content being viewed by others

Data availability

The datasets supporting the results of this article are included within the article.

References

Wang YM, Suo SF, Li YJ et al (2016) Research report on the development strategy of high end bearings. Tsinghua University Press, Beijing

Kim SJ (2021) Analytical consideration of the radial clearance to reduce cage slip of the turbo engine roller bearing. J Mech Sci Technol 35(7):2827–2839. https://doi.org/10.1007/s12206-021-0606-0

Yang ZH, Chen H, Yu TX (2018) Effects of rolling bearing configuration on stiffness of machine tool spindle. Proc Inst Mech Eng, Part C: J Mech Eng Sci 232(5):775–785. https://doi.org/10.1177/0954406217693659

Zhang YQ, Tan QC, Li JG et al (2012) Fatigue life of taper roller bearings in drive rear axle main gear reducer. Mach , Mater Sci Eng App 510:112–116. https://doi.org/10.4028/www.scientific.net/AMR.510.112

Doll GL (2022) Surface engineering in wind turbine tribology. Surf Coatings Technol 442:128545. https://doi.org/10.1016/j.surfcoat.2022.128545

Yang TY, Ding Q, Guo T et al (2016) Analysis of local damage vibration characteristics in the axle bearings of high-speed train bogies. J Vibr , Meas Diag 36(4):665-673, 808. https://doi.org/10.16450/j.cnki.1004-6801.2016.04.009

Liu TW, Zhang N, Liang W et al (2014) Failure simulation analysis and experimental verification of bearings for spaceborne moving mechanism. China Mec Eng 21:2864–2868. https://doi.org/10.3969/j.issn.1004-132X.2014.21.005

Liu DL, Jiang T, He YH et al (2015) Discussion on failure problems of aero-bearing. Fail Anal Prev 5:324–330. https://doi.org/10.3969/j.issn.1673-6214.2015.05.012

Xiong WL, Yang JP, An Q (2015) Effect of bearing roller machining precision on the dynamic performance of high speed motorized spindle. J East China Univ Sc Technol 45(5):831–838. https://doi.org/10.14135/j.cnki.1006-3080.20180613002

Darisuren S, Amanov A, Pyun YS (2019) Improvement in fatigue life of needle roller bearing. Tribol Lubr 35(4):237–243. https://doi.org/10.9725/kts.2019.35.4.237

Wang W, Hadfield M, Wereszczak AA (2009) Surface strength of silicon nitride in relation to rolling contact performance. Ceram Int 35(8):3339–3346. https://doi.org/10.1016/j.ceramint.2009.05.034

Tong VC, Hong SW (2017) Study on the stiffness and fatigue life of tapered roller bearings with roller diameter error. Proc Inst Mech Eng Part J-J Eng Tribol 231(2):176–188. https://doi.org/10.1177/1350650116649889

GB/T 4661-2015 (2015) Rolling bearings-Cylindrical rollers. https://std.samr.gov.cn/gb/search/gbDetailed?id=71F772D80EB0D3A7E05397BE0A0AB82A

China Bearing Industry Association (2022) Outline of the 14th five year plan for the development of the national bearing industry. http://www.chinacaj.net/i,16,14776,0.html

Wang Y, Wang YH, Han TH et al (2019) Improvement on finishing technology for chamfer of cylindrical rollers. Bearing 10:57. https://doi.org/10.19533/j.issn1000-3762.2019.10.005

Inasaki I, Karpuschewski B, Lee HS (2001) Grinding chatter - origin and suppression. CIRP Annals 50(2):515–534. https://doi.org/10.1016/S0007-8506(07)62992-8

Garitaonandia I, Albizuri J, Hernandez-Vazquez JM et al (2013) Redesign of an active system of vibration control in a centerless grinding machine: Numerical simulation and practical implementation. Precis Eng J Int Soc Precis Eng Nanotechnol 37(3):562–571. https://doi.org/10.1016/j.precisioneng.2013.01.001

Zakharov OV, Datskovskaya EA (2010) Setup of centerless superfinishing machine tools. Russian Eng Res 30(12):1263–1267. https://doi.org/10.3103/S1068798X10120191

Taniguchi N (1983) Current status in, and future trends of, ultraprecision machining and ultrafine materials processing. CIRP Annals – Manufact Technol 32(2):573–582. https://doi.org/10.1016/S0007-8506(07)60185-1

Wang X, Zhao P, Lyu BH et al (2019) Research status of ultra-precision machining technologies for working surfaces of rolling bearings. China Mech Eng 30(11):1301–1309. https://doi.org/10.3969/j.issn.1004-132X.2019.11.006

Zhou FF, Yuan JL, Yao WF et al (2019) Review on ultra-precision machining technology of precision balls. China Mech Eng 30(13):1528–1539. https://doi.org/10.3969/j.issn.1004-132X.2019.13.003

Jiang L, Zheng JX, Peng WM et al (2022) Research progress of ultra-precision polishing technologies for basic components of spacecraft. Surface Technol 51(12):1–19. https://doi.org/10.16490/j.cnki.issn.1001-3660.2022.12.001

Yao WF, Yuan JL, Zhong MP et al (2019) Review on precision machining technology for outer diameters of cylindrical rollers. China Mech Eng 30(10):1195–1206. https://doi.org/10.3969/j.issn.1004-132X.2019.10.009

Chu MQ, Ding RG, Zhang SY et al (2021) Surface integrity for machining aerospace parts. Mater Rep 35(7):7183–7189. https://doi.org/10.11896/cldb.19100143

Wang DF, Yuan JL, Wang YS et al (2022) Research progresses on surface integrity of bearing grooves. China Mech Eng 33(18):2143–2160. https://doi.org/10.3969/j.issn.1004-132X.2022.18.001

Cui L, Su Y (2022) Contact fatigue life prediction of rolling bearing considering machined surface integrity. Indust Lubr Tribol 74(1):73–80. https://doi.org/10.1108/ILT-08-2021-0345

Guan J (2019) Influence of rough surface on damage evolution and fatigue life of M50-bearing steel containing a spherical inclusion. Int J Damage Mech 28(10):1580–1604. https://doi.org/10.1177/1056789519842367

Ueda T, Mitamura N (2009) Mechanism of dent initiated flaking and bearing life enhancement technology under contaminated lubrication condition. Part II. Tribol Int 42(11-12):1832–1837. https://doi.org/10.1016/j.triboint.2008.12.010

Guan J (2019) Research on rolling contact fatigue damage behavior of M50 bearing steel in aeroenging rolling bearing. PhD thesis, Harbin Institute of Technology. https://doi.org/10.27061/d.cnki.ghgdu.2019.000416

Heim LR (1918) Roll grinding machine. US: 1264930. https://patentscope2.wipo.int/search/zh/detail.jsf?docId=US34174939

Cui Q, Cheng K, Chen SJ et al (2017) An innovative investigation on the workpiece kinematics and its roundness generation in through-feed centreless grinding. Proc Inst Mech Eng, Part B: J Eng Manuf 231(7):1131–1143. https://doi.org/10.1177/0954405415585378

Cui Q, Chen SJ, Ding H et al (2016) Dynamic model of material removal process in through-feed centerless grinding based on the Lagrange equation. Key Eng Mater 667(1):173–180. https://doi.org/10.4028/www.scientific.net/KEM.667.173

Safarzadeh H, Leonesio M, Bianchi G et al (2020) Roundness prediction in centreless grinding using physics-enhanced machine learning techniques. Int J Adv Manuf Technol 112(3-4):1051–1063. https://doi.org/10.1007/s00170-020-06407-2

Hashimoto F, Gallego I, Oliveira JFG et al (2012) Advances in centerless grinding technology. CIRP Annals-Manufact Technol 61(2):747–770. https://doi.org/10.1016/j.cirp.2012.05.003

Yalovoy OA, Zakharov OV, Kochetkov AV (2015) The adaptive control of accuracy at centerless grinding of rolling bearings. IOP Conf Series: Mater Sci Eng 93(1):12063. https://doi.org/10.1088/1757-899x/93/1/012063

Cui Q, Ding H, Cheng K (2015) An analytical investigation on the workpiece roundness generation and its perfection strategies in centreless grinding. Proc Inst Mech Eng , Part B: J Eng Manuf 229(3):409–420. https://doi.org/10.1177/0954405414530899

Cui Q, Chen S, Ding H et al (2016) An investigation on the workpiece roundness generation in centerless grinding based on the integration of virtual machine tool and workpiece material removal mechanism. Key Eng Mater 667(1):588–594. https://doi.org/10.4028/www.scientific.net/KEM.667.588

Cui Q (2015) An investigation on the rounding process and virtual machining system for high precision centerless grinding. PhD thesis, Harbin Institute of Technology.

Rowe W (2014) Rounding and stability in centreless grinding. Int J Machine Tools Manuf 82-83:1–10. https://doi.org/10.1016/j.ijmachtools.2014.03.004

Safarzadeh H, Monno H (2022) Continuous multi-angle variation (CMAV) for faster roundness correction in centreless grinding. Int J Adv Manuf Technol 119(11-12):7517–7531. https://doi.org/10.1007/s00170-021-08647-2

Otaghvar MH, Hahn B, Werner H et al (2018) A novel approach to roundness generation analysis in centerless through-feed grinding in consider of decisive parameters of grinding gap by use of 3d kinematic simulation. Procedia CIRP 77:247–250. https://doi.org/10.1016/j.procir.2018.09.007

Otaghvar MH, Hahn B, Werner H et al (2019) Optimization of centerless through-feed grinding using 3d kinematic simulation (conference paper). Procedia CIRP 79:308–312. https://doi.org/10.1016/j.procir.2019.02.072

Adrian C, Daniela P (2016) The study of kinetic energy variation during centerless grinding in the conditions of adaptive control. 2016 International Conference on Applied and Theoretical Electricity (Icate), Craiova, Romania. https://www.webofscience.com/wos/alldb/full-record/WOS:000390767500062

Barrenetxea D, Mancisidor I, Beudaert X et al (2018) Increased productivity in centerless grinding using inertial active dampers. CIRP Annals – Manuf Technol 67(1):337–340. https://doi.org/10.1016/j.cirp.2018.04.093

Gao ZB, Gao HY (2016) Analysis of grinding wheel profile in feeding-through centerless grinding of tapered roller. J Mech Eng Res Dev 39(1):134–141

Hänel A, Teicher U, Pätzold H et al (2018) Investigation of a carbon fibre-reinforced plastic grinding wheel for high-speed plunge-cut centreless grinding application. Proc Inst Mech Eng , Part B: J Eng Manuf 232(14):2663–2669. https://doi.org/10.1177/0954405417690556

Trubitsyn AV, Svirshchev VI, Flegentov VK (2014) Force required in centerless external grinding of superhard powder composites. Russian Eng Res 34(3):180–182. https://doi.org/10.3103/S1068798X14030162

Zhou FF, Zhang XL, Yuan JL et al (2021) Analysis on grinding result for large size cylindrical roller with logarithmic crown. Bearing 2. https://doi.org/10.19533/j.issn1000-3762.2021.02.006

Cernaianu A (2014) The Analysis of the Temperature Influence on the Processing Precision in Centerless Grinding Machines. In: Applied Mechanics and Materials, vol 659. Trans Tech Publications Ltd, pp 331–336

Mondal SC, Mandal P (2015) An application of particle swarm optimization technique for optimization of surface roughness in centerless grinding operation. International Conference on Research into Design, Bangalore. https://d.wanfangdata.com.cn/conference/CC0215050457

Barbosa E, Santos Delfino A, Brandão L (2017) The use of alternative coolant techniques to reduce the environmental impact in the use of water in through-feed centreless grinding. Int J Adv Manuf Technol 91(9-12):3417–3425. https://doi.org/10.1007/s00170-017-0030-x

Neto LMG, Rodriguez RL, Lopes JC et al (2022) Application of optimized lubri-cooling technique in through-feed centerless grinding process of bearing steel sae 52100. Int J Adv Manuf Technol 120(1-2):515–526. https://doi.org/10.1007/s00170-022-08686-3

Xu WX, Wu YB (2018) A novel approach to fabricate high aspect ratio micro-rod using ultrasonic vibration-assisted centreless grinding. Int J Mech Sci 141:21–30. https://doi.org/10.1016/j.ijmecsci.2018.03.038

Xu WX, Wu YB (2012) Simulation investigation of through-feed centerless grinding process performed on a surface grinder. J Mater Proc Technol 212(4):927–935. https://doi.org/10.1016/j.jmatprotec.2011.12.002

Xu WX, Cui DD, Wu YB (2016) Sphere forming mechanisms in vibration-assisted ball centreless grinding. Int J Mach Tools Manuf 108:83–94. https://doi.org/10.1016/j.ijmachtools.2016.06.004

Shuo YQ, Wu X, Wang TJ et al (2006) Manufacturing equipment of rolling bearing. China Machine Press, Beijing

Xia XT, Li H, Hao G et al (2002) Theory and application of centerless grinding. National Defence Industry Press, Beijing

Chang SH, Farris TN, Chandrasekar S (2008) Experimental analysis on evolution of superfinished surface texture. J Mater Proc Technol 203(1-3):365–371. https://doi.org/10.1016/j.jmatprotec.2007.10.032

Puthanangady TK, Malkin S (1995) Experimental investigation of the superfinishing process. Wear 185(1-2):173–182

Yang BS (2017) Research on contact characteristics between oilstones and rollers in through-feed superfinishing of taper rollers. Master thesis, Henan University of Science and Technology.

Chang SH, Farris TN, Chandrasekar S (2000) Contact mechanics of superfinishing. J Tribol 122(2):388–393. https://doi.org/10.1115/1.555374

Chang SH, Farris TN, Chandrasekar S (2003) Experimental characterization of superfinishing. Proc Inst Mech Eng , Part B: J Eng Manuf 217(7):941–951. https://doi.org/10.1243/09544050360686815

Onishi T, Ohashi K, Higashi K et al (2014) Development of an advanced machine control system in superfinishing the automatic determination of the suitable machining time. Adv Mater Res 1017:515–519. https://doi.org/10.4028/www.scientific.net/AMR.1017.515

Varghese B, Malkin S (2000) Selection of optimal superfinishing parameters. J Manuf Proc 2(2):124–130

Varghese B, Malkin S (2001) Rounding and lobe formation during superfinishing. J Manuf Proc 3(2):102–107. https://doi.org/10.1016/S1526-6125(01)70125-9

Soutome T, Sato K (2009) Study on superposition superfinishing (1st report)(Article). Nihon Kikai Gakkai Ronbunshu, C Hen/Transactions of the Japan Society of Mechanical Engineers, Part C 75(751):741–748. https://doi.org/10.1299/kikaic.75.741

Gao ZB, Yang XB, Guo XC (2018) Analysis on convexity during superfinishing of tapered rollers with cone-cylinder matching guide rollers. Bearing 12:17–23. https://doi.org/10.19533/j.issnl000-3762.2018.12.005

Gao ZB, Li QL (2014) Particularity of superfinishing technology for rolling bearings. Bearing 8:53–58

Gao ZB, Ma W, Deng XZ et al (2013) Analysis of crown generating mechanism in fixed posture through-feed superfinishing of taper rollers. J Mech Eng 23:96–104. https://doi.org/10.3901/JME.2013.23.096

Xue JX, Jia SY, Yang BS (2016) The polish properties analysis of through-feed superfinishing tapered roller. Manuf Automat 38(1):33–37

Xue JX, Yang BS, Jia SY (2017) Analysing cutting edge of taper roller and oilstone in fixed posture through-feed superfinishing. Mech Sci Technol Aerosp Eng 36(8):1244–1249. https://doi.org/10.13433/j.cnki.1003-8728.2017.0816

Xue JX, Yang BS, Wang LN et al (2017) Processing characteristic analysis on through-feed superfinishing of tapered rollers. Bearing 6:21–26. https://doi.org/10.19533/j.issnl000-3762.2017.06.005

Jia SY (2016) Study on abrading characteristics and motion stability in through-feed superfinishing for tapered roller. Master thesis, Henan University of Science and Technology.

Wang LN (2018) Study on wear mechanism of oilstone and roller in through-feed superfinishing for tapered roller. Master thesis, Henan University of Science and Technology.

Jia SX, Gao ZB, Tang Z et al (2020) Numerical simulation analysis of crown profiling during median putting through-feed superfinishing of tappered roller. Bearing 5:10–18. https://doi.org/10.19533/j.issn1000-3762.2020.05.003

Di HX, Wang H, Lyu YS et al (2021) Kinetics simulation of the abrasives grain ordered arrangement oilstone in superfinishing uniform texture surface process. Mach Tool Hydr 49(2):10–14. https://doi.org/10.3969/j.issn.1001-3881.2021.02.003

Di HX (2020) Study on several problems of superfinishing structured surface by ordered abrasive oilstone. Master thesis, Shenyang Ligong University.

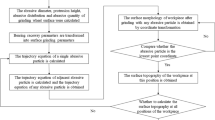

Yao WF, Liu JW, Huang J et al (2022) Improvement of roundness in centerless finishing of bearing steel rollers by taguchi method in experiments and simulation. Int J Adv Manuf Technol 118(9-10):2853–2872. https://doi.org/10.1007/s00170-021-08020-3

Yao WF, Chu QQ, Lyu BH et al (2022) Modeling of material removal based on multi-scale contact in cylindrical polishing. Int J Mech Sci 223:107287. https://doi.org/10.1016/j.ijmecsci.2022.107287

Hu YT (2010) Study on electrochemical-mech finishing of bearing roller. Master thesis, Dalian University of Technology.

Wei ZF, Li L, She DS (2018) Effect of electrochemical mechanical machining on surface quality and convexity of bearing rollers. Surface Technol 47(7):119–124. https://doi.org/10.16490/j.cnki.issn.1001-3660.2018.07.016

Wei ZF (2013) Key issues of electrochemical mechanical machining with non-uniform mechanical effect. PhD thesis, Dalian University of Technology.

Xu WJ, Wei ZF, Sun J et al (2012) Surface quality prediction and processing parameter determination in electrochemical mechanical polishing of bearing rollers. Int J Adv Manuf Technol 63(1-4):129–136. https://doi.org/10.1007/s00170-011-3891-4

Xu WJ, Wei ZF, Sun J et al (2012) Surface quality prediction and processing parameters determination on electrochemical mechanical finishing of bearing roller. China Mech Eng 5:525–530. https://doi.org/10.3969/j.issn.1004-132X.2012.05004

Wei ZF, Zheng XH, Tao B (2013) Research of bearing crown roller-raceway by non-uniform interelectrode gap electrochemical mechanical machining. Mater Des Proc Appl , Parts 1-4(690-693):2475. https://doi.org/10.4028/www.scientific.net/AMR.690-693.2475

Zheng XH, Wei ZF, Bin T (2013) Simulation and experimental research of bearing crown roller-raceway by non-uniform time effect electrochemical mechanical machining. Adv Mater Res 721:377–381. https://doi.org/10.4028/www.scientific.net/AMR.721.377

Wei ZF, Zhang SW, She DS et al (2021) Study on the effect of electrochemical mechanical machining on surface quality of shaft/bearing parts. J Bohai Univ (Natural Science Edition) 42(1):70–77

Umehara N, Kalpakjian S (1994) Magnetic fluid grinding – a new technique for finishing advanced ceramics. CIRP Annals 43(1):185–188. https://doi.org/10.1016/S0007-8506(07)62192-1

Umehara N, Komanduri R (1996) Magnetic fluid grinding of hip-Si3N4 rollers. Wear 192(1):85–93. https://doi.org/10.1016/0043-1648(95)06763-9

Komanduri R, Hou ZB, Umehara N et al (1999) A “gentle” method for finishing Si3N4 balls for hybrid bearing applications. Tribol Lett 7(1):39–49. https://doi.org/10.1023/A:1019144630946

Umehara N, Kirtane T, Gerlick R et al (2005) A new apparatus for finishing large size/large batch silicon nitride (Si3N4) balls for hybrid bearing applications by magnetic float polishing (MFP). Int J Mach Tools Manuf 46(2):151–169. https://doi.org/10.1016/j.ijmachtools.2005.04.015

Umehara N, Kato K (1996) Magnetic fluid grinding of advanced ceramic balls. Wear 200(1):148–153. https://doi.org/10.1016/S0043-1648(96)07297-3

Childs THC, Mahmood S, Yoon HJ (1995) Magnetic fluid grinding of ceramic balls. Tribol Int 28(6):341–348. https://doi.org/10.1016/0301-679X(95)00018-Y

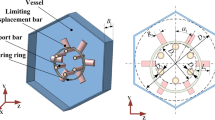

Yang WF (2015) Study on processing method for high precision bearing rollers with high consistency based on uniform distribution of cylindrical processing trajectory. PhD thesis, Zhejiang University of Technology.

Yuan JL, Yao WF, Zhao P et al (2015) Kinematics and trajectory of both-sides cylindrical lapping process in planetary motion type. Int J Mach Tools Manuf 92:60–71. https://doi.org/10.1016/j.ijmachtools.2015.02.004

Yao WF, Yuan JL, Jiang L et al (2018) Study on both-side cylindrical ultra-precision lapping and polishing processes in eccentric rotations. China Mech Eng 29(19):2327–2334. https://doi.org/10.3969/j.issn.1004⁃132X.2018.19.009

Cheng ZD, Yao WF, Zheng B et al (2015) Effect of motion types on cylindrical surface topography. Surface Technol 44(10):117–123. https://doi.org/10.16490/j.cnki.issn.1001-3660.2015.10.020

Su J, Yuan JL, Zhang S et al (2018) Experiment on optimization of lapping cylindrical roller. Diamond and Abrasives. Engineering 38(2):82–88. https://doi.org/10.13394/j.cnki.jgszz.2018.2.0017

Zhang CT (2017) Research on the processing equipment of high precision double plane cylindrical roller. Master thesis, Zhejiang University of Technology.

Jiang L, Yao WF, He YY et al (2016) An experimental investigation of double-side processing of cylindrical rollers using chemical mechanical polishing technique. Int J Adv Manuf Technol 82(1-4):523–534. https://doi.org/10.1007/s00170-015-7370-1

He YL (2015) Research on the double disc and eccentric straight groove lapping method for cylindrical roller. Master thesis, Tianjin University.

Cai ZJ (2017) Design of circulatory system for roller cylindrical surface processing with double-disc straight groove lapping process. Master thesis, Tianjin University.

Deng XF, Ren CZ, Chen Y et al (2020) Research on material selection of lapping tools for double-disc and linear-groove lapping method based on friction and wear experiment. Chinese J Eng Des 27(6):720–728. https://doi.org/10.3785/j.issn.1006-754X.2020.00.086

Chen Y, Ren CZ, Deng XF et al (2021) Research on rotating motion of cylindrical roller based on double-disc straight groove grinding. Chinese J Eng Des 28(2):179–189. https://doi.org/10.3785/j.issn.1006-754X.2021.00.008

Chen Y (2020) Research on rotating motion of cylindrical roller based on double disc straight groove grinding. Master thesis, Tianjin University.

He QS, He CL, Chen G et al (2021) Analysis and experiments of stable rotation conditions for cylindrical rollers in double disc straight groove lapping. China Mech Eng 32(21):2625–2634. https://doi.org/10.3969/j.issn.1004-132X.2021.21.012

Yang L, Ren CZ (2019) Simulation and propulsion experimental analysis of electromagnetic propulsion device for cylindrical roller. Chinese J Eng Des 26(5):611–618. https://doi.org/10.3785/j.issn.1006-754X.2019.05.015

Li M, Lyu BH, Yuan JL et al (2015) Shear-thickening polishing method. Int J Mach Tools Manuf 94:88–99. https://doi.org/10.1016/j.ijmachtools.2015.04.010

Li M, Yuan JL, Lyu BH et al (2017) Shear-thickening polishing of Si3N4 Ceramics. J Mech Eng 53(9):193–200. https://doi.org/10.3901/JME.2017.09.193

Chen SH, Lyu BH, He QK et al (2019) Simulation and experimental study on material removal function of shear thickening polishing cylindrical surface. Surface Technol 48(10):355–362. https://doi.org/10.16490/j.cnki.issn.1001-3660.2019.10.044

Li M (2015) Fundamental research on shear-thickening polishing method. PhD thesis, Hunan University.

Li M, Lyu BH, Yuan JL et al (2016) Material removal mathematics model of shear thickening polishing. J Mech Eng 52(7):142–151. https://doi.org/10.3901/JME.2016.07.142

Li M, Yuan JL, Lyu BH (2015) Preparation of shear thickening polishing abrasive slurries and their polishing properties. Optics Precis Eng 9:2513–2521. https://doi.org/10.3788/OPE.20152309.2513

Dai WT, Lyu BH, Weng HZ et al (2015) Experiments on the effects of acoustic properties in acoustic assisted shear thickening polishing. International Manufacturing Conference In China, Hangzhou

Dai WT (2016) Study on high efficiency acoustic assisted shear thickening polishing method. Master thesis, Zhejiang University of Technology.

Dai WT, Lyu BH, Weng HZ et al (2016) Optimization experiment of acoustic assisted shear thickening polishing of cylindrical surface. Surface Technol 2:188–193. https://doi.org/10.16490/j.cnki.issn.1001-3660.2016.02.030

Li M, Liu MH, Riemer O et al (2021) Origin of material removal mechanism in shear thickening-chemical polishing. Int J Mach Tools Manuf 170:103800. https://doi.org/10.1016/j.ijmachtools.2021.103800

He QK (2019) Research on force-induced rheological polishing slurry based on material characteristics of cemented carbide. Master thesis, Zhejiang University of Technology.

Tang C (2019) Study on preparation and properties of polishing slurry with shear thickening and chemical effect. Master thesis, Hunan University of Science and Technology.

Weng HZ (2017) Basic study on high efficiency electrolysis compounded shear thickening polishing method. Master thesis, Zhejiang University of Technology.

Zhou DD, Huang XM, Ming Y et al (2021) Material removal characteristics of magnetic-field enhanced shear thickening polishing technology. J Mater Res Technol 15:2697–2710. https://doi.org/10.1016/j.jmrt.2021.09.092

Yang SQ, Li WH, Chen HL et al (2011) Surface finishing theory and new technology. National Defense Industry Press, Beijing. https://doi.org/10.16490/j.cnki.issn.1001-3660.2019.10.002

Yang SQ, Li WH, Li XH et al (2019) Research development of mass finishing for high-performance parts. Surface Technol 48(10):13–24

Hashimoto Y, Ito T, Nakayama Y et al (2021) Fundamental investigation of gyro finishing experimental investigation of contact force between cylindrical workpiece and abrasive media under dry condition. Precis Eng 67:123–136. https://doi.org/10.1016/j.precisioneng.2020.09.009

Frechette M, Sroka G, Bell M (2012) High speed, automatable superfinishing of rear-axle hypoid gears. SAE 2012 World Congress & Exhibition. Detroit, Michigan, USA

Chang C, Ma Z, Yang SQ et al (2019) Investigation into the surface integrity of crankshaft by barrel finishing. Proc Inst Mech Eng , Part E: J Proc Mech Eng 235(6):2019–2026. https://doi.org/10.1177/09544089211026865

Boschetto A, Bottini L, Macera L et al (2020) Post-processing of complex SLM parts by barrel finishing. Appl Sci 10(4):1382. https://doi.org/10.3390/app10041382

Eifler M, Garretson I, Linke B et al (2019) Effects of vibratory finishing of 304 stainless steel samples on areal roughness parameters: a correlational analysis for anisotropy parameters. J Mater Proc Technol 273:116256. https://doi.org/10.1016/j.jmatprotec.2019.116256

Bergs T, Müller U, Barth S et al (2021) Experimental analysis on vibratory finishing of cemented carbides. Manuf Lett 28:21–24. https://doi.org/10.1016/j.mfglet.2021.02.004

Plichta J, Juniewicz M (2020) Research on the influence of workpiece orientation during processing in disc centrifugal machine on the geometrical structure of its surface and processing efficiency. J Mech Energy Eng 4(44):221–226. https://doi.org/10.30464/jmee.2020.4.3.221

Hernandez-Garcia C, Bullard D, Hannon F et al (2017) High voltage performance of a dc photoemission electron gun with centrifugal barrel-polished electrodes. Rev Sci Instrum 88(9):093303. https://doi.org/10.1063/1.4994794

Li XH, Li WH, Yang SQ et al (2018) Study on polyurethane media for mass finishing process: dynamic characteristics and performance. Int J Mech Sci 138:250–261. https://doi.org/10.1016/j.ijmecsci.2018.02.017

Han W (2001) Application of Rolling Element Polishing Technology in Practical Production. Bearing 8:21–23

Liu CJ, Chu ZF (2003) Application of Polishing technology in surface machining of bearing rollers. Bearing Indust 12:30–32

Wu GS, Zhang Y (2005) Application of polishing technology in bearings roller process. J Harbin Bearing 26(1):12-13, 15

Hashimoto F, Yamaguchi H, Krajnik P et al (2016) Abrasive fine-finishing technology. CIRP Annals-Manuf Technol 65(2):597–620. https://doi.org/10.1016/j.cirp.2016.06.003

Li XH, Wang XF, Yang YB et al (2022) A multi-chamber ultra-precision centrifugal finishing apparatus and method for bearing rolling element surfaces. China: ZL202210649802.X. https://d.wanfangdata.com.cn/patent/ChJQYXRlbnROZXdTMjAyMjEyMDcSEENOMjAyMjEwNjQ5ODAyLlgaCHlzZ2Zpbjk0

Balan MR, Tufescu A, Cretu SS (2016) A case study on relation between roughness, lubrication and fatigue life of rolling bearings. IOP Conf Series: Mater Sci Eng 147(1):012013. https://doi.org/10.1088/1757-899X/147/1/012013

Lorenz SJ, Sadeghi F, Trivedi HK et al (2021) A continuum damage mechanics finite element model for investigating effects of surface roughness on rolling contact fatigue. Int J Fatigue 143:105986. https://doi.org/10.1016/j.ijfatigue.2020.105986

Yusof NFM, Ripin ZM (2014) Analysis of surface parameters and vibration of roller bearing. Tribol Trans 57(4):715–729. https://doi.org/10.1080/10402004.2014.895887

Yang X, Li YC, Liu GM et al (2019) Effect of surface roughness on elastohydrodynamic lubrication performance of cylindrical roller bearing. Tehnicki vjesnik / Technical Gazette 26(3):710–721. https://doi.org/10.17559/TV-20190104091451

Trung D, Nguyen N (2021) Investigation of the surface roughness in infeed centerless grinding of scm435 steel. Int J Automat Technol 15(1):123–130. https://doi.org/10.20965/ijat.2021.p0123

Khan ZA, Siddiquee AN, Sheikh MH (2012) Selection of optimal condition for finishing of centreless-cylindrical ground parts using grey relational and principal component analyses. Int J Mater Prod Technol 43(1-4):2–21. https://doi.org/10.1504/IJMPT.2012.047636

Sun L (2013) Research on shear thickening mechanism and prescription of non-newtonian polishing slurry. Master thesis, Zhejiang University of Technology.

Dong CC(2015) Research on material removal mechanism of shear thickening polishing and characteristics of polishing slurry. Master thesis, Zhejiang University of Technology.

Khoi PB, Trung DD, Cuong N et al (2015) Research on optimization of plunge centerless grinding process using genetic algorithm and response surface method. Int J Sci Eng Technol 4(3):207–211

Yu YJ, Li JS, Xue YJ (2022) Influence of roundness errors of bearing components on rotational accuracy of cylindrical roller bearings. Sci Rep 12(1):1–17. https://doi.org/10.1038/s41598-022-07718-y

Huang J, Li CY, Chen BK (2021) Mechanical behaviors of cross roller bearings with raceway roundness error. J Central South Univ 28(7):2091–2104. https://doi.org/10.1007/s11771-021-4755-1

Liu J, Li XB, Yu WN (2020) Vibration analysis of the axle bearings considering the combined errors for a high-speed train. Proc Inst Mech Eng , Part K: J Multi-body Dyn 234(3):481–497. https://doi.org/10.1177/1464419320917235

Bu JZ (2020) Study on the influence of inner ring roundness error on vibration in cylindrical roller bearings. Mach China (18):59–61

Zheng HW, He HX, He M et al (2014) Determination of superfinishing process parameters for cylindrical rollers D42218N3W. Bearing 10:16–18

Rascalha A, Brandão LC, Ribeiro Filho SLM (2013) Optimization of the dressing operation using load cells and the taguchi method in the centerless grinding process. Int J Adv Manuf Technol 67(5-8):1103–1112. https://doi.org/10.1007/s00170-012-4551-z

Xu WP (2018) The evolution of contour form on the rotary surface by centerless grinding and electrochemical superfine composite machining. Master thesis, Dalian Polytechnic University.

Hu L, Zha J, Zhao WH et al (2022) Multi-dimensional controllability analysis of precision ball bearing integrity. Adv Manuf. https://doi.org/10.1007/s40436-022-00424-y

Funding

The work was co-supported by the National Natural Science Foundation of China (Grant No. 51975399 and 52075362) and the Central Government Guides Local Foundation for Science and Technology Development (Grant No. YDZJSX2022A020 and YDZJSX2022B004).

Author information

Authors and Affiliations

Contributions

Xingfu Wang designed and performed the manuscript, analyzed the data, and drafted the manuscript. Xiuhong Li provided valuable research suggestions, guidance, and funding support, and participated in the revision and review of the paper. Xiaolong Ma, Wenhui Li and Shengqiang Yang analyzed the data. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent to publication

All authors have consent for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Li, X., Ma, X. et al. Advance on surface finishing technology of precision bearing cylindrical rollers. Int J Adv Manuf Technol 131, 2341–2363 (2024). https://doi.org/10.1007/s00170-023-11595-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11595-8