Abstract

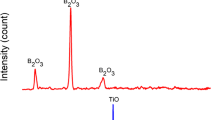

Metal matrix nanocomposites have attracted worldwide interest due to their applications in several industrial sectors. However, metal matrix powder preparation is an important factor to consider during additive manufacturing of composites. In this work, the potential of laser metal deposition (LMD) to produce composite deposits from powders feedstock obtained by high-energy ball milling materials is presented. Inconel 718/Al2O3 nanocomposite processed by sonication-assisted high-energy ball milling was deposited in the form of single-clad track via LMD. Commercial Inconel 718 powder without alumina was also evaluated to compare the effect of the ceramic nanoparticles. IN718/Al2O3 composite was successfully deposited by LMD on IN718 substrates. It was found that Al2O3 nanoparticles were partially retained and mostly distributed at the upper regions of the single-clad tracks. Alumina-enriched zones were formed in situ during solidification at the surface of the single-clad tracks. These segregation regions were identified as spinel-type oxides based on Al–Ti–Cr constituents. Al–Ti and/or Al–Ti–O reaction occurs during melting due to their high reactivity as elemental materials.

Similar content being viewed by others

References

Brandt M (2016) Laser additive manufacturing: materials, design, technologies, and applications. Woodhead Publishing, Sawston

Wohlers T, Campbell I (2016) Wohlers report 2016. Wohlers Associates. Inc.: Fort Collins, CO, USA

Toyserkani E, Khajepor A, Corbin S (2005) Laser cladding. CRC Press LLC, USA

Bambach M, Sizova I, Silze F, Schnick M (2018) Hot workability and microstructure evolution of the nickel-based superalloy Inconel 718 produced by laser metal deposition. J Alloys Compd 740:278–287. https://doi.org/10.1016/j.jallcom.2018.01.029

Han P (2017) Additive design and manufacturing of jet engine parts. Engineering 3(5):648–652. https://doi.org/10.1016/J.ENG.2017.05.017

López-Baltazar EA, Ruiz-Luna H, Baltazar-Hernández VH, Ruiz-Mondragón JJ, Ibarra-Medina J, Alvarado-Orozco JM (2019) Effect of the average energy on WC grain growth of WC-10Co-4Cr composite by laser cladding. Metals 9:19–22

Yu WH, Sing SL, Chua CK, Kuo CN, Tian XL (2019) Particle-reinforced metal matrix nanocomposites fabricated by selective laser melting: a state of the art review. Prog Mater Sci J 104:330–379

Song B, Wang Z, Yan Q, Zhang Y, Zhang J, Cai C, Wei Q, Shi Y (2017) A integral method of preparation and fabrication of metal matrix composite: selective laser melting of in-situ nano/submicro-sized carbides reinforced iron matrix composites. Mater Sci Eng A 707:478–487. https://doi.org/10.1016/j.msea.2017.09.092

Zhou Y, Wen S, Wang C, Duan L, Wei Q, Shi Y (2019) Effect of TiC content on the Al-15Si alloy processed by selective laser melting: microstructure and mechanical properties. Opt Laser Technol 120:105719

Miracle DB, Donaldson SL, ASM H (2001) Vol. 21: Composites. ASM International, Metals Park, OH, USA

Chen H, Gu D, Deng L, Lu T, Kühn U, Kosiba K (2021) Laser additive manufactured high-performance Fe-based composites with unique strengthening structure. J Mater Sci Technol 89:242–252

Chen T, Wu F, Wang H, Liu D (2018) Laser cladding in-situ Ti(C, N) particles reinforced Ni-based composite coatings modified with CeO2 nanoparticles. Metals 8:601

Reed RC (2006) The superalloys fundamentals and applications. Press CU, UK

Schafrik RE, Ward DD, Groh JR (2001) Application of alloy 718 in GE aircraft engines: past, present and next five years. Superalloys 718(625):1–11

Choi J, Shin G, Yang S, Yang D, Lee J, Brochu M, Yu J (2017) Densification and microstructural investigation of Inconel 718 parts fabricated by selective laser melting. Powder Technol 310:60–66. https://doi.org/10.1016/j.powtec.2017.01.030

Vasudev H, Thakur L, Singh H, Bansal A (2020) An investigation on oxidation behaviour of high velocity oxy-fuel sprayed Inconel718-Al2O3 composite coatings. Surf Coat Technol 393:125770. https://doi.org/10.1016/j.surfcoat.2020.125770

Hong C, Gu D, Dai D, Gasser A, Weisheit A, Kelbassa I, Zhong M, Poprawe R (2013) Laser metal deposition of TiC/Inconel 718 composites with tailored interfacial microstructures. Opt Laser Technol 54:98–109. https://doi.org/10.1016/j.optlastec.2013.05.011

Rong T, Gu D (2016) Formation of novel graded interface and its function on mechanical properties of WC1-x reinforced Inconel 718 composites processed by selective laser melting. J Alloys Compd 680:333–342. https://doi.org/10.1016/j.jallcom.2016.04.107

Zhang H, Gu D, Ma C, Xia M, Guo M (2019) Surface wettability and superhydrophobic characteristics of Ni-based nanocomposites fabricated by selective laser melting. Appl Surf Sci 476:151–160. https://doi.org/10.1016/j.apsusc.2019.01.060

Wilson JM, Shin YC (2012) Microstructure and wear properties of laser-deposited functionally graded Inconel 690 reinforced with TiC. Surf Coat Technol 207:517–522. https://doi.org/10.1016/j.surfcoat.2012.07.058

Tian Z, Zhao Y-T, Jiang Y-J, Ren H-P (2021) Microstructure and properties of Inconel 625 + WC composite coatings prepared by laser cladding. Rare Met 40:2281–2291. https://doi.org/10.1007/s12598-020-01507-0

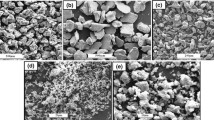

Márquez-Martínez P, Martínez-Franco E, Cuenca-Alvarez R, Hurtado-Macías A, García-Moreno AI, Alvarado-Orozco JM, Ruiz-Luna H (2022) Processing and characterization of Inconel 718/Al2O3 nanocomposite powder fabricated by different techniques. Powder Technol 398:117124. https://doi.org/10.1016/j.powtec.2022.117124

Khalili A, Goodarzi M, Mojtahedi M, Torkamany MJ (2016) Solidification microstructure of in-situ laser-synthesized Fe-TiC hard coating. Surf Coat Technol 307:747–752. https://doi.org/10.1016/j.surfcoat.2016.09.051

Pacheco JT, João L, Barbetta LD, Ferreira HS (2020) Laser cladding of Stellite-6 on AISI 316 L austenitic stainless steel : empirical-statistical modeling and parameter optimization. Lasers Manuf Mater Process 8:1–14

Sá de Sousa JM, de Souza Pinto Pereira A, Pereira M, Gomes R, Silva N (2020) Influence of laser metal deposition direction in the abrasive and adhesive wear resistance of Ni-Cr-B-Si coatings. J Laser Appl 32:1–7

Muvvala G, Karmakar DP, Kumar A (2017) Online monitoring of thermo-cycles and its correlation with microstructure in laser cladding of nickel based super alloy. Opt Lasers Eng 88:139–152. https://doi.org/10.1016/j.optlaseng.2016.08.005

Zhu H, Ouyang M, Hu J, Zhang J, Qiu C (2021) Design and development of TiC-reinforced 410 martensitic stainless steel coatings fabricated by laser cladding. Ceram Int 47(9):12505–12513. https://doi.org/10.1016/j.ceramint.2021.01.108

Gopinath M, Karmakar DP, Nath AK (2018) In-process detection of microstructural changes in laser cladding of in-situ Inconel 718/TiC metal matrix composite coating. J Alloys Compd 740:545–558. https://doi.org/10.1016/j.jallcom.2017.12.364

Sun RL, Lei YW, Niu W (2008) Laser clad TiC reinforced NiCrBSi composite coatings on Ti–6Al–4V alloy using a CW CO2 laser. Surf Coat Technol 203(10–11):1395–1399. https://doi.org/10.1016/j.surfcoat.2008.11.012

Zhou W, Kikuchi K, Nomura N, Yoshimi K, Kawasaki A (2020) In-situ formation of ceramic layer on Mo-based composites via laser powder bed fusion. Materialia 10:100655. https://doi.org/10.1016/j.mtla.2020.100655

Dev Singh D, Arjula S, Raji Reddy A (2021) Functionally graded materials manufactured by direct energy deposition: a review. Mater Today Proc 47:2450–2456

Chen Y, Liou F (2018) Additive manufacturing of metal functionally graded materials: a review. Solid Free Fabr 2018 Proc 29th Annu Int Solid Free Fabr Symp – An Addit Manuf Conf

Pietrzak K, Kaliński D, Chmielewski M (2007) Interlayer of Al2O3–Cr functionally graded material for reduction of thermal stresses in alumina–heat resisting steel joints. J Eur Ceram Soc 27(2–3):1281–1286

Acknowledgements

The authors thanks to CONACYT Consortium in Additive Manufacturing (CONMAD) for the use of experimental facilities for this work.

Funding

This work was financially supported by Consejo Nacional de Ciencia y Tecnología (CONACyT—Mexico) under projects no. CB-2016–01-286086, AEM-275781, TAMU-CONACYT Project ID 2017–007, and master’s scholarship and the program Investigadores por México-Conacyt (Project Numbers 2015–85 and 730), COZCyT.

Author information

Authors and Affiliations

Contributions

Haideé Ruiz-Luna, conceptualization-data curation, investigation, design, formal analysis, writing—original draft, writing—review and editing, funding acquisition, project administration; Pedro Márquez-Martínez, conceptualization-data curation, investigation, design, methodology, data collection; Ángel Iván García-Moreno, writing—review and editing; Juan Manuel Alvarado-Orozco, writing—review and editing, funding acquisition, project administration; Enrique Martínez-Franco, conceptualization-data curation, investigation, design, formal analysis, methodology, data collection, writing—original draft, writing—review and editing, project administration.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ruiz-Luna, H., Márquez-Martínez, P., García-Moreno, Á.I. et al. Laser metal deposition of mechanical milled IN718/Al2O3 nanocomposite. Int J Adv Manuf Technol 127, 1189–1197 (2023). https://doi.org/10.1007/s00170-023-11577-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11577-w