Abstract

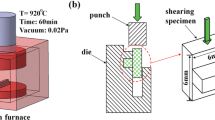

Since the hot forming of TC4 alloy after diffusion bonding has extensive applications in aerospace and medical industries, it is practically significant to explore the influence of diffusion bonding on the alloy’s hot formability and identify the optimal forming parameters. Therefore, dual-stage diffusion bonding of aviation grade TC4 is carried out firstly at 900 °C for 1 h and then at 930 °C for 2 h under 2-MPa normal pressure in \(5.0\times {10}^{-3}\)-Pa vacuum atmosphere. Another block of the as-received alloy is subjected to the same thermal loading as the diffusion bonding process. The diffusion-bonded and heat-treated alloys are then subjected to uniaxial tensile tests at \(750-900\) °C and \({0.0001-0.1\mathrm{ s}}^{-1}\). Based on the tensile test data, the constitutive and dynamic material models are developed to investigate diffusion bonding effects on the alloy’s hot forming behavior and identify optimal forming conditions. The developed constitutive model showed good predictability. The apparent activation energy of diffusion bonded (440 \(-\) 510 \(\mathrm{kJ}\cdot {\mathrm{mole}}^{-1}\)) and heat-treated (400 \(\mathrm{kJ}\cdot {\mathrm{mole}}^{-1}\)) alloys indicated that dynamic recrystallization and recovery are the primary deformation mechanisms. The processing maps revealed that diffusion bonding expanded the instability domain and lowered the dissipation efficiency, limiting the safe working conditions of the alloy. The analysis of deformed microstructure validated the findings of processing maps. The optimal processing conditions of \(800\) °C /0.0001 s–1 and 850 °C /0.0001 s–1 are discovered for diffusion-bonded and heat-treated alloys, respectively.

Graphical Abstract

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this article.

References

Xun YW, Tan MJ (2000) Applications of superplastic forming and diffusion bonding to hollow engine blades. J Mater Process Technol 99:80–85. https://doi.org/10.1016/S0924-0136(99)00377-5

Hefti LD (2008) Innovations in the superplastic forming and diffusion bonded process. J Mater Eng Perform 17:178–182. https://doi.org/10.1007/s11665-007-9178-0

Burkhart ET, Hefti L (2020) Advancements of superplastic forming and diffusion bonding of titanium alloys for heat critical aerospace applications. SAE Int J Adv Curr Pract Mobil 2:1202–1208. https://doi.org/10.4271/2020-01-0033

Chandrappa K, Sumukha CS, Sankarsh BB, Gowda R (2020) Superplastic forming with diffusion bonding of titanium alloys. Mater Today: Proc 27:2909–2913. https://doi.org/10.1016/j.matpr.2020.03.514

Lee HS, Yoon JH, Yi YM, Shin DH (2007) Superplastic characteristics and diffusion bonding of Ti-6Al-4V alloy. Key Eng Mater 345:549–552. https://doi.org/10.4028/www.scientific.net/KEM.345-346.549

Mosleh AO, Mikhaylovskaya AV, Kotov AD, Kwame JS (2019) Experimental, modelling and simulation of an approach for optimizing the superplastic forming of Ti-6%Al-4%V titanium alloy. J Manuf Process 45:262–272. https://doi.org/10.1016/j.jmapro.2019.06.033

Trân R, Reuther F, Winter S, Psyk V (2020) Process development for a superplastic hot tube gas forming process of titanium (Ti-3Al-2.5V) hollow profiles. Metals 10:1150. https://doi.org/10.3390/met10091150

Australian Transport Safety Bureau (2020) Engine failure involving Airbus A330, 9M-XXE, near Carnarvon, Western Australia, on 25 June 2017. 62 Northbourne Avenue Canberra, Australian Capital Territory

Wu X, Chen M, Xie L, Zhang T, Hu Z (2015) Twist-bend forming of aeroengine titanium TC4 wide-chord hollow fan blade with complex geometries. Acta Aeronaut Astonaut Sin 36:2055–2063. https://doi.org/10.7527/S1000-6893.2014.0271

Chen M, Wu X, Xie L, Wang N, Su N (2019) Two-layer process and optimal blank design for hollow titanium wide-chord fan blades with complex geometries. Rare Met Mater Eng 48:1717–1724

Li C, Sardar MI, Lang L, Guo Y, Li X, Alexandrova S, Zhang D (2022) Hot deformation behavior and strain compensation constitutive model of equiaxed fine grain diffusion-welded micro-duplex TC4 titanium alloy. Chin J Aeronaut. https://doi.org/10.1016/J.CJA.2022.07.025

Ma X, Zeng W, Tian F, Zhou Y, Sun Y (2012) Optimization of hot process parameters of Ti-6.7Al-2Sn-2.2Zr-2.1Mo-1W-0.2Si alloy with lamellar starting microstructure based on the processing map. Mater Sci Eng, A 545:132–138. https://doi.org/10.1016/j.msea.2012.03.011

Seshacharyulu T, Medeiros SC, Frazier WG, Prasad YVRK (2000) Hot working of commercial Ti-6Al-4V with an equiaxed α-β microstructure: Materials modeling considerations. Mater Sci Eng A 284:184–194. https://doi.org/10.1016/s0921-5093(00)00741-3

Park CH, Ko YG, Park JW, Lee CS (2008) Enhanced superplasticity utilizing dynamic globularization of Ti-6Al-4V alloy. Mater Sci Eng A 496:150–158. https://doi.org/10.1016/j.msea.2008.05.001

Peng X, Guo H, Shi Z, Qin C, Zhao Z, Yao Z (2014) Study on the hot deformation behavior of TC4-DT alloy with equiaxed α+β starting structure based on processing map. Mater Sci Eng A 605:80–88. https://doi.org/10.1016/j.msea.2014.03.047

Matsumoto H, Velay V (2017) Mesoscale modeling of dynamic recrystallization behavior, grain size evolution, dislocation density, processing map characteristic, and room temperature strength of Ti-6Al-4V alloy forged in the (α+β) region. J Alloy Compd 708:404–413. https://doi.org/10.1016/j.jallcom.2017.02.285

Zhang W, Ding H, Zhao J, Yang B, Yang W (2018) Hot deformation behavior and processing maps of Ti-6Al-4V alloy with starting fully lamellar structure. J Mater Res 33:3677–3688. https://doi.org/10.1557/jmr.2018.331

Bodunrin MO, Chown LH, van der Merwe JW, Alaneme KK (2019) Hot working of Ti-6Al-4V with a complex initial microstructure. IntJ Mater Form 12:857–874. https://doi.org/10.1007/s12289-018-1457-9

Liu Q, Hui S, Tong K, Yu Y, Ye W, Song SY (2019) Investigation of high temperature behavior and processing map of Ti-6Al-4V-0.11Ru titanium alloy. J Alloys Compd 787:527–536. https://doi.org/10.1016/j.jallcom.2019.02.046

Yang X, Wang Y, Dong X, Peng C, Ji B, Xu Y, Li W (2021) Hot deformation behavior and microstructure evolution of the laser solid formed TC4 titanium alloy. Chin J Aeronaut 34:163–182. https://doi.org/10.1016/j.cja.2020.07.036

Wu H, Li X, Mei Q, Chen J, Wu G (2019) A Flow behavior of diffusion bonding interface of Ti6Al4V alloy over a wide range of strain rates. Mater Sci Eng A 761:138067. https://doi.org/10.1016/j.msea.2019.138067

Zener C, Hollomon JH (1944) Effect of strain rate upon plastic flow of steel. J Appl Phys 15:22–32. https://doi.org/10.1063/1.1707363

Sellars CM, McTegart WJ (1966) On the mechanism of hot deformation. Acta Metall 14:1136–1138. https://doi.org/10.1016/0001-6160(66)90207-0

Wang H, Zhao K, Chu X, Zhao B, Gao J (2019) Constitutive modelling and microscopic analysis of TC4 alloy sheet at elevated temperature. Results Phys 13:102332. https://doi.org/10.1016/j.rinp.2019.102332

N R (2011) Metals for superplastic forming. In: Superplastic Forming of Advanced Metallic Materials. Woodhead Publishing, pp 3–33

Ling CP, McCormick PG (1993) Constitutive modelling of strain rate sensitivity. In: Advances in Engineering Plasticity and its Applications, p 217–222. https://doi.org/10.1016/B978-0-444-89991-0.50030-5

Yan SL, Yang H, Li HW, Yao X (2016) Variation of strain rate sensitivity of an aluminum alloy in a wide strain rate range: mechanism analysis and modeling. J Alloy Compd 688:776–786. https://doi.org/10.1016/j.jallcom.2016.07.077

Ning Y, Yao Z, Guo H, Fu MW, Li H, Xie X (2010) Investigation on hot deformation behavior of P/M Ni-base superalloy FGH96 by using processing maps. Mater Sci Eng A 527:6794–6799. https://doi.org/10.1016/j.msea.2010.07.040

Du Z, Jiang S, Zhang K (2015) The hot deformation behavior and processing map of Ti-47.5Al-Cr-V alloy. Mater Des 86:464–473. https://doi.org/10.1016/j.matdes.2015.07.027

Ning YQ, Xie BC, Liang HQ, Li H, Yang XM, Guo HZ (2015) Dynamic softening behavior of TC18 titanium alloy during hot deformation. Mater Des 71:68–77. https://doi.org/10.1016/j.matdes.2015.01.009

Chai X, Zhang X, Wang Z, Liu Y (2015) Modeling of the diffusion bond for SPF/DB titanium hollow structures. Int J Aerospace Eng 2015:1–9. https://doi.org/10.1155/2015/694564

Narayana Murty SVS, Nageswara Rao B, Kashyap BP (2000) Instability criteria for hot deformation of materials. Int Mater Rev 45:15–26. https://doi.org/10.1179/095066000771048782

Prasad YVRK (2003) Processing maps: a status report. J Mater Eng Perform 12:638–645. https://doi.org/10.1007/s11665-013-0732-7

Al Omar A, Prado JM (2012) Criteria for prediction of plastic instabilities for hot working processes (part I: theoretical review). Weld Int 26:921–934. https://doi.org/10.1080/09507116.2011.592704

Kumar AK (1987) Criteria for predicting metallurgical instabilities in processing. Indian Institute of Science, Bangalore

Sardar MI, Li C, Lang L, Guo Y, Ali H, Haq F, Alexandrova S, Jiang J, Han H (2022) An investigation into Arrhenius type constitutive models to predict complex hot deformation behavior of TC4 alloy having bimodal microstructure. Mater Today Commun 31:103622. https://doi.org/10.1016/j.mtcomm.2022.103622

Giuliano G (2011) Superplastic forming of advanced metallic materials—methods and applications, 1st edn. Woodhead Publishing Limited, UK

Mavromihales M, Mason J, Weston W (2003) A case of reverse engineering for the manufacture of wide chord fan blades (WCFB) used in Rolls Royce aero engines. J Mater Process Technol 134:279–286. https://doi.org/10.1016/S0924-0136(02)01108-1

Peng Y, Li J, Li Z, Li S, Guo W, Gao X, Xiong J (2022) Interfacial voids and microstructure evolution, bonding behavior and deformation mechanism of TC4 diffusion bonded joints. J Manuf Process 81:837–851. https://doi.org/10.1016/j.jmapro.2022.07.037

Lin Y, Chen M-S, Zhong J (2008) Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput Mater Sci 42:470–477. https://doi.org/10.1016/j.commatsci.2007.08.011

Rudnytskyj A, Simon P, Jech M, Gachot C (2020) Constitutive modelling of the 6061 aluminium alloy under hot rolling conditions and large strain ranges. Mater Des 190:108568. https://doi.org/10.1016/j.matdes.2020.108568

Curtin WA, Olmsted DL, Hector LG (2006) A predictive mechanism for dynamic strain ageing in aluminium–magnesium alloys. Nat Mater 5:875–880. https://doi.org/10.1038/nmat1765

Nieh TG, Wadsworth J (1997) Microstructural characteristics and deformation properties in superplastic intermetallics. Mater Sci Eng A 239–240:88–96. https://doi.org/10.1016/s0921-5093(97)00564-9

Guo W, Jia Q, Li R, Li W (2017) The superplastic deformation behavior and phase evolution of Ti-6Al-4V alloy at constant tensile velocity. High Temp Mater Process (London) 36:55–62. https://doi.org/10.1515/htmp-2015-0205

Seshacharyulu T, Medeiros SC, Morgan JT, Malas JC, Frazier WG, Prasad YVRK (1999) Hot deformation mechanisms in ELI grade Ti-6A1-4V. Scripta Mater 41:283–288. https://doi.org/10.1016/S1359-6462(99)00163-3

Jia W, Zeng W, Zhou Y, Liu J, Wang Q (2011) High-temperature deformation behavior of Ti60 titanium alloy. Mater Sci Eng A 528:4068–4074. https://doi.org/10.1016/j.msea.2011.01.113

Funding

This work was supported by National Natural Science Foundation of China (No. 51675029).

Author information

Authors and Affiliations

Contributions

Conceptualization: all authors. Experimentation and data acquisition: Sardar Muhammad Imran, Can Li, Bo Zang. Analysis and interpretation of data: Sardar Muhammad Imran, Can Li. Modeling and validation: Sardar Muhammad Imran, Can Li. Drafting the manuscript: Sardar Muhammad Imran. Revising the manuscript critically for important intellectual content: Lang Lihui, Jun Jiang, Li Yong, Xiaoxing Li.

Corresponding author

Ethics declarations

Consent to participate

All the authors agreed to participate in this research study and hereby grant consent to The International Journal of Advance Manufacturing Technology, the rights to publish this article. None of the material has been published or is under consideration for publication elsewhere. All the authors hereby confirm that this manuscript is their original work, and the citations have been marked with references.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Imran, S.M., Li, C., Lang, L. et al. An analysis of the hot forming characteristics of diffusion-bonded TC4 alloy using processing maps. Int J Adv Manuf Technol 127, 3239–3253 (2023). https://doi.org/10.1007/s00170-023-11556-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11556-1