Abstract

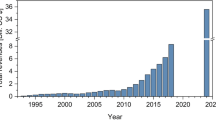

In recent years, fused filament fabrication (FFF) has become the most popular additive manufacturing (AM) process due to its low cost and relative simplicity, which incorporates a variety of sustainable benefits to lower energy use and material waste. Machine learning (ML) methods have been widely applied to evaluate the energy efficiency performance of the designed part, enabling AM designers to minimize the energy consumption of the fabrication process by redesigning part geometry and process parameters before physical fabrication. However, recent ML methods are data-hungry and prone to ignore the difference of spatial size of parts, which thereby causes evaluation performance degradation and intolerable economical burden. To this end, the multi-scale hierarchical transformer (MSHT) network is proposed to economically evaluate energy efficiency performance. The MSHT does not necessitate a substantial number of annotated labels or require training and testing datasets having the same spatial size. MSHT is equipped with the hierarchical transformer encoder that is designed as a four-stage feature hierarchy, efficiently enabling the solid integration of the multi-grained scale embeddings. Extensive numerical and physical experimental results demonstrate that the proposed method consistently outperforms the state-of-the-art networks and enhances the capability of economically evaluating energy efficiency performance for fused filament fabrication.

Similar content being viewed by others

Availability of data and material

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

Code Availability

The codes are available from the corresponding author on reasonable request.

References

Gutierrez-Osorio AH, Ruiz-Huerta L, Caballero-Ruiz A, Siller HR, Borja V (2019) Energy consumption analysis for additive manufacturing processes. Int J Adv Manuf Technol 105(1):1735–1743

Yosofi M, Kerbrat O, Mognol P (2019) Additive manufacturing processes from an environmental point of view: a new methodology for combining technical, economic, and environmental predictive models. Int J Adv Manuf Technol 102(9):4073–4085

Cao D, Malakooti S, Kulkarni VN, Ren Y, Lu H (2021) Nanoindentation measurement of core-skin interphase viscoelastic properties in a sandwich glass composite. Mech Time-Depend Mater 25(3):353–363

Cao D, Malakooti S, Kulkarni VN, Ren Y, Liu Y, Nie X, Qian D, Griffith DT, Lu H (2022) The effect of resin uptake on the flexural properties of compression molded sandwich composites. Wind Energy 25(1):71–93

Wang X, Xu T, de Andrade MJ, Rampalli I, Cao D, Haque M, Roy S, Baughman RH, Lu H (2021) The interfacial shear strength of carbon nanotube sheet modified carbon fiber composites. In: Challenges in Mechanics of Time Dependent Materials, vol 2. Springer, pp 25–32

Wang K, Song Y, Sheng H, Xu J, Zhang S, Qin J (2022) Energy efficiency design for eco-friendly additive manufacturing based on multimodal attention fusion. J Manuf Process 79:720–730

Roque R, Barbosa GF, Guastaldi AC (2021) Design and 3d bioprinting of interconnected porous scaffolds for bone regeneration. an additive manufacturing approach. J Manuf Process 64:655–663

Jiang J, Xiong Y, Zhang Z, Rosen DW (2022) Machine learning integrated design for additive manufacturing. J Intell Manuf 33(4):1073–1086

Kumar R, Kumar M, Chohan JS (2021) The role of additive manufacturing for biomedical applications: a critical review. J Manuf Process 64:828–850

Baumers M, Duflou JR, Flanagan W, Gutowski TG, Kellens K, Lifset R (2017) Charting the environmental dimensions of additive manufacturing and 3D printing. J Ind Econ 21(S1)

Xu J, Wang K, Sheng H, Gao M, Zhang S, Tan J (2020) Energy efficiency optimization for ecological 3d printing based on adaptive multi-layer customization. J Clean Prod 245:118826

Wang K, Xu J, Zhang S, Tan J (2022) Antivibration and energy efficiency design for large stroke additive manufacturing based on dynamic trajectory adaption. Int J Adv Manuf Technol 118(9):3015–3034

Kellens K, Mertens R, Paraskevas D, Dewulf W, Duflou JR (2017) Environmental impact of additive manufacturing processes: does AM contribute to a more sustainable way of part manufacturing? Procedia Cirp 61:582–587

Gutowski T, Jiang S, Cooper D, Corman G, Hausmann M, Manson JA, Schudeleit T, Wegener K, Sabelle M, Ramos-Grez J et al (2017) Note on the rate and energy efficiency limits for additive manufacturing. J Ind Ecol 21(S1):S69–S79

Baumers M, Tuck C, Bourell D, Sreenivasan R, Hague R (2011) Sustainability of additive manufacturing: measuring the energy consumption of the laser sintering process. Proc Inst Mech Eng B J Eng Manuf 225(12):2228–2239

Yi L, Ravani B, Aurich JC (2020) Development and validation of an energy simulation for a desktop additive manufacturing system. Addit Manuf 32:101021

Baumers M, Tuck C, Wildman R, Ashcroft I, Rosamond E, Hague R (2013) Transparency built-in: energy consumption and cost estimation for additive manufacturing. J Ind Ecol 17(3):418–431

Qin J, Hu F, Liu Y, Witherell P, Wang CC, Rosen DW, Simpson T, Lu Y, Tang Q (2022) Research and application of machine learning for additive manufacturing. Addit Manuf 102691

Wang K, Song Y, Huang Z, Sun Y, Xu J, Zhang S (2022) Additive manufacturing energy consumption measurement and prediction in fabricating lattice structure based on recallable multimodal fusion network. Measurement 196:111215

Wang K, Yu L, Xu J, Zhang S, Qin J (2022b) Energy consumption intelligent modeling and prediction for additive manufacturing via multisource fusion and inter-layer consistency. Comput Ind Eng 108720

Majeed A, Zhang Y, Ren S, Lv J, Peng T, Waqar S, Yin E (2021) A big data-driven framework for sustainable and smart additive manufacturing. Robot Comput Integr Manuf 67:102026

Huff TJ, Ludwig PE, Zuniga JM (2018) The potential for machine learning algorithms to improve and reduce the cost of 3-dimensional printing for surgical planning. Expert Rev Med Devices 15(5):349–356

Sreenivasan R, Bourell DL (2009) Sustainability study in selective laser sintering–an energy perspective. In: 2009 International Solid Freeform Fabrication Symposium, University of Texas at Austin

Watson J, Taminger K (2018) A decision-support model for selecting additive manufacturing versus subtractive manufacturing based on energy consumption. J Clean Prod 176:1316–1322

Li Y, Hu F, Qin J, Ryan M, Wang R, Liu Y (2021) A hybrid machine learning approach for energy consumption prediction in additive manufacturing. In: Pattern Recognition. ICPR International Workshops and Challenges: Virtual Event, January 10–15, 2021, Proceedings, Part IV. Springer, pp 622–636

Hu F, Qin J, Li Y, Liu Y, Sun X (2021) Deep fusion for energy consumption prediction in additive manufacturing. Procedia CIRP 104:1878–1883

Wang K, Xu J, Zhang S, Tan J, Qin J (2023) Towards low-budget energy efficiency design in additive manufacturing based on variational scale-aware transformer. J Clean Prod 136168. https://doi.org/10.1016/j.jclepro.2023.136168

Nieto DM, Molina SI (2020) Large-format fused deposition additive manufacturing: a review. Rapid Prototyp J 26(5):793–799

He K, Zhang X, Ren S, Sun J (2016) Deep residual learning for image recognition. In: Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition. pp 770–778

Wang F, Jiang M, Qian C, Yang S, Li C, Zhang H, Wang X, Tang X (2017) Residual attention network for image classification. In: Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition. pp 3156–3164

Hu J, Shen L, Sun G (2018a) Squeeze-and-excitation networks. In: Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition. pp 7132–7141

Hu J, Shen L, Albanie S, Sun G, Vedaldi A (2018b) Gather-excite: Exploiting feature context in convolutional neural networks. Adv Neural Inf Proces Syst 31

Tan M, Le Q (2019) Efficientnet: rethinking model scaling for convolutional neural networks. In: International Conference on Machine Learning. PMLR, pp 6105–6114

Wang X, Girshick R, Gupta A, He K (2018) Non-local neural networks. In: Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition. pp 7794–7803

Vaswani A, Shazeer N, Parmar N, Uszkoreit J, Jones L, Gomez AN, Kaiser Ł, Polosukhin I (2017) Attention is all you need. In: Proceedings of the 31st International Conference on Neural Information Processing Systems. pp 5998–6008

Dosovitskiy A, Beyer L, Kolesnikov A, Weissenborn D, Zhai X, Unterthiner T, Dehghani M, Minderer M, Heigold G, Gelly S, et al (2020) An image is worth 16x16 words: transformers for image recognition at scale. Preprint at http://arxiv.org/abs/2010.11929

Heo B, Yun S, Han D, Chun S, Choe J, Oh SJ (2021) Rethinking spatial dimensions of vision transformers. Preprint at http://arxiv.org/abs/2103.16302

Touvron H, Cord M, Douze M, Massa F, Sablayrolles A, Jégou H (2021) Training data-efficient image transformers & distillation through attention. In: International Conference on Machine Learning. PMLR, pp 10347–10357

Liu Z, Lin Y, Cao Y, Hu H, Wei Y, Zhang Z, Lin S, Guo B (2021) Swin transformer: hierarchical vision transformer using shifted windows. Preprint at http://arxiv.org/abs/2103.14030

Chollet F (2017) Xception: deep learning with depthwise separable convolutions. In: Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition. pp 1251–1258

Howard AG, Zhu M, Chen B, Kalenichenko D, Wang W, Weyand T, Andreetto M, Adam H (2017) Mobilenets: efficient convolutional neural networks for mobile vision applications. Preprint at http://arxiv.org/abs/1704.04861

Baevski A, Auli M (2018) Adaptive input representations for neural language modeling. Preprint at http://arxiv.org/abs/1809.10853

Xu W, Xu Y, Chang T, Tu Z (2021) Co-scale conv-attentional image transformers. In: Proceedings of the IEEE/CVF International Conference on Computer Vision. pp 9981–9990

Tuli S, Dasgupta I, Grant E, Griffiths TL (2021) Are convolutional neural networks or transformers more like human vision? Preprint at http://arxiv.org/abs/2105.07197

Islam MA, Jia S, Bruce ND (2020) How much position information do convolutional neural networks encode? Preprint at http://arxiv.org/abs/2001.08248

Ozdemir Z, Hernandez-Nava E, Tyas A, Warren JA, Fay SD, Goodall R, Todd I, Askes H (2016) Energy absorption in lattice structures in dynamics: experiments. Int J Impact Eng 89:49–61

Zhao C, Lui CF, Du S, Wang D, Shao Y (2023) An earth mover’s distance based multivariate generalized likelihood ratio control chart for effective monitoring of 3D point cloud surface. Comput Ind Eng 175:108911

Selvaraju RR, Cogswell M, Das A, Vedantam R, Parikh D, Batra D (2017) Grad-cam: visual explanations from deep networks via gradient-based localization. In: Proceedings of the IEEE International Conference on Computer Vision. pp 618–626

Wang K (2023) Contrastive learning-based semantic segmentation for In-situ stratified defect detection in additive manufacturing. J Manuf Syst 68:465–476. https://doi.org/10.1016/j.jmsy.2023.05.001

Funding

This research was funded by Key Laboratory of Advanced Manufacturing Technology of Zhejiang Province (No. 2023KF04).

Author information

Authors and Affiliations

Contributions

Kang WANG: Conceptualization, Methodology, Software, Formal analysis, Writing - original draft, Writing - review & editing, Visualization. Jinghua XU: Resources. Shuyou ZHANG: Supervision. Jianrong TAN: Resources.

Corresponding author

Ethics declarations

Ethical Approval

The type of study is non-human subject research, and waived the need for informed consent.

Consent to participate

All authors have read and agreed to participate the manuscript.

Consent for publication

All authors have read and agreed to the published version of the manuscript.

Conflicts of Interest

The authors declare no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, K., Xu, J., Zhang, S. et al. Economically evaluating energy efficiency performance in fused filament fabrication using a multi-scale hierarchical transformer. Int J Adv Manuf Technol 128, 329–343 (2023). https://doi.org/10.1007/s00170-023-11553-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11553-4