Abstract

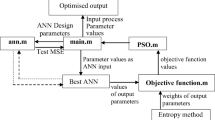

Laser cutting technology has proven advantageous in processing high-hardness metals, ceramics, and composites. However, the process parameters significantly influence the kerf and heat-affected zone widths. Therefore, it is necessary to establish an accurate prediction model of laser cutting quality to optimize the process parameters and improve processing quality and efficiency. This work proposes a laser-cutting quality prediction model based on an artificial neural network optimized by the particle swarm optimization algorithm. The particle swarm optimization algorithm is used to optimize the number of nodes in the hidden layer, activation function, initial weights, and biases for a more accurate model. This model considers the effects of average power, repetition frequency, and scan speed on the kerf width, heat-affected width, and processing efficiency. The non-dominated sorting genetic algorithm II is adopted for the process parameter optimization. Finally, the experiments are carried out to verify the model. The results show that the model has a high accuracy with a prediction error of less than 10% for kerf width and heat-affected zone. Moreover, the optimized process parameters meet the given machining targets and increase the machining efficiency by over 40%.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

Code availability

The authors confirm that the codes supporting the findings of this study are available from the authors.

References

Boudjemline A, Boujelbene M, Bayraktar E (2020) Surface quality of Ti-6Al-4V titanium alloy parts machined by laser cutting. Eng Technol Appl Sci Res 10(4):6062–6067. https://doi.org/10.48084/etasr.3719

Parthiban A, Dhanasekaran C, Sivaganesan S, Sathish S (2020) Modeling on surface cut quality of CO2 laser cutting for austenitic stainless steel sheet. Mater Today: Proc 21:823–827. https://doi.org/10.1016/j.matpr.2019.07.428

Wang J, Sun Z, Gu L, Azimy H (2021) Investigating the effect of laser cutting parameters on the cut quality of Inconel 625 using Response Surface Method (RSM). Infrared Phys Technol 118:103866. https://doi.org/10.1016/j.infrared.2021.103866

Luo Y, Wang H, Li Z, Wang X, Xie G (2019) Morphology investigation of sectional stripes and adhering slag based on vapor-to-melt ratio in Nd: YAG laser cutting of Al2O3 ceramics. J Laser Appl 31(3):032014. https://doi.org/10.2351/1.5093762

Raza MS, Datta S, Bule B, Saha P (2019) Parametric study of laser cutting of carbon fibre reinforced polymer (CFRP) and the effect of fibre orientation on cutting quality. Adv Mater Process Technol 5(2):202–212. https://doi.org/10.1080/2374068X.2018.1564865

Singh Y, Singh J, Sharma S, Aggarwal V, Pruncu CI (2021) Multi-objective optimization of kerf-taper and surface-roughness quality characteristics for cutting-operation on coir and carbon fibre reinforced epoxy hybrid polymeric composites during CO2-pulsed laser-cutting using RSM. Lasers Manuf Mater Process 8(2):157–182. https://doi.org/10.1007/s40516-021-00142-6

Chaki S, Bose D, Bathe RN (2020) Multi-objective optimization of pulsed Nd: YAG laser cutting process using entropy-based ANN-PSO model. Lasers Manuf Mater Process 7(1):88–110. https://doi.org/10.1007/s40516-019-00109-8

Joshi P, Sharma A, Kumar Modi Y (2018) Optimization of process parameters during laser cutting of Ni-based superalloy thin sheet using response surface methodology. Mater Today: Proc 5(11):24231–24239. https://doi.org/10.1016/j.matpr.2018.10.218

Adalarasan R, Santhanakumar M, Rajmohan M (2015) Optimization of laser cutting parameters for Al6061/SiCp/Al2O3 composite using grey based response surface methodology (GRSM). Measurement 73:596–606. https://doi.org/10.1016/j.measurement.2015.06.003

Patel A, Bhavsar SN (2021) Experimental investigation to optimize laser cutting process parameters for difficult to cut die alloy steel using response surface methodology. Mater Today: Proc 43:28–35. https://doi.org/10.1016/j.matpr.2020.11.201

Tamilarasan A, Rajamani D (2017) Multi-response optimization of Nd:YAG laser cutting parameters of Ti-6Al-4V superalloy sheet. J Mech Sci Technol 31(2):813–821. https://doi.org/10.1007/s12206-017-0133-1

Vagheesan S, Govindarajalu J (2019) Hybrid neural network–particle swarm optimization algorithm and neural network–genetic algorithm for the optimization of quality characteristics during CO2 laser cutting of aluminium alloy. J Braz Soc Mech Sci Eng 41(8):328. https://doi.org/10.1007/s40430-019-1830-8

Chaki S, Bathe RN, Ghosal S, Padmanabham G (2018) Multi-objective optimisation of pulsed Nd:YAG laser cutting process using integrated ANN–NSGAII model. J Intell Manuf 29(1):175–190. https://doi.org/10.1007/s10845-015-1100-2

Baldovino RG, Valenzuela IC, Bandala AA, Dadios EP (2018) Optimization of CO2 laser cutting parameters using adaptive neuro-fuzzy inference system (ANFIS). J Telecommun Electron Comput Eng 10(1–9):103–107

Kusuma AI, Huang Y-M (2022) Product quality prediction in pulsed laser cutting of silicon steel sheet using vibration signals and deep neural network. J Intell Manuf. https://doi.org/10.1007/s10845-021-01881-1

Nguyen D-T, Jeng-Rong H, Pi-Cheng T, Chih-Kuang L (2021) Prediction of kerf width in laser cutting of thin non-oriented electrical steel sheets using convolutional neural network mathematics. 9(18):2261. https://doi.org/10.3390/math9182261

Alizadeh A, Omrani H (2019) An integrated multi response Taguchi- neural network- robust data envelopment analysis model for CO2 laser cutting. Measurement 131:69–78. https://doi.org/10.1016/j.measurement.2018.08.054

Yang C-B, Deng C-S, Chiang H-L (2012) Combining the Taguchi method with artificial neural network to construct a prediction model of a CO2 laser cutting experiment. Int J Adv Manuf Technol 59(9):1103–1111. https://doi.org/10.1007/s00170-011-3557-2

Madić MJ, Radovanović MR (2011) Optimal selection of ANN training and architectural parameters using Taguchi method: a case study. FME Trans 39(2):79–86

Yongbin Y, Bagherzadeh SA, Azimy H, Akbari M, Karimipour A (2020) Comparison of the artificial neural network model prediction and the experimental results for cutting region temperature and surface roughness in laser cutting of AL6061T6 alloy. Infrared Phys Technol 108:103364. https://doi.org/10.1016/j.infrared.2020.103364

Wang X (2013) Electric Power client credit assessment based on GA optimized BP neural network. In: Proceedings of the 2nd International Conference on Green Communications and Networks 2012 (GCN 2012). Springer Berlin Heidelberg, Berlin

Chen B, Zhang H, Li M (2019) Prediction of pK(a) values of neutral and alkaline drugs with particle swarm optimization algorithm and artificial neural network. Neural Comput Appl 31(12):8297–8304. https://doi.org/10.1007/s00521-018-3956-5

Qian K, Zhichao H, Dengke S (2020) Sound quality estimation of electric vehicles based on GA-BP artificial neural networks. Appl Sci 10(16):5567. https://doi.org/10.3390/app10165567

Lee Y, Oh SH, Kim MW (1991) The effect of initial weights on premature saturation in back-propagation learning. In: IJCNN-91-Seattle International Joint Conference on Neural Networks. https://doi.org/10.1109/IJCNN.1991.155275.

Jesus RJ, Antunes ML, da Costa RA, Dorogovtsev SN, Mendes JFF, Aguiar RL (2021) Effect of initial configuration of weights on training function of artificial neural networks. Mathematics 9(18):2246. https://doi.org/10.3390/math9182246

Du Y, Li Y (2008) Sonar array azimuth control system based on genetic neural network. In: 2008 7th World Congress on Intelligent Control and Automation. https://doi.org/10.1109/WCICA.2008.4592874

Zhu C, Zhang J, Liu Y, Ma D, Li M, Xiang B (2020) Comparison of GA-BP and PSO-BP neural network models with initial BP model for rainfall-induced landslides risk assessment in regional scale: a case study in Sichuan, China. Nat Hazards 100(1):173–204. https://doi.org/10.1007/s11069-019-03806-x

Han H-G, Qiao J-F (2013) A structure optimisation algorithm for feedforward neural network construction. Neurocomputing 99:347–357. https://doi.org/10.1016/j.neucom.2012.07.023

Kan X, Fan Y, Fang Z, Cao L, Xiong NN, Yang D, Li X (2021) A novel IoT network intrusion detection approach based on adaptive particle swarm optimization convolutional neural network. Inf Sci 568:147–162. https://doi.org/10.1016/j.ins.2021.03.060

Fernandes Junior FE, Yen GG (2019) Particle swarm optimization of deep neural networks architectures for image classification. Swarm Evol Comput 49:62–74. https://doi.org/10.1016/j.swevo.2019.05.010

Jagtap AD, Kawaguchi K, Karniadakis GE (2020) Adaptive activation functions accelerate convergence in deep and physics-informed neural networks. J Comput Phys 404:109136. https://doi.org/10.1016/j.jcp.2019.109136

Wang Y, Yong LYS, Xuewen R (2020) The influence of the activation function in a convolution neural network model of facial expression recognition. Appl Sci 10(5):1897. https://doi.org/10.3390/app10051897

Bülbül MA, Ehsan H, Işık IM, Hosseini SEA, Işık E (2022) A hybrid ANN-GA model for an automated rapid vulnerability assessment of existing RC buildings. Appl Sci 12(10):5138. https://doi.org/10.3390/app12105138

Ding H, Wang Z, Guo Y (2020) Multi-objective optimization of fiber laser cutting based on generalized regression neural network and non-dominated sorting genetic algorithm. Infrared Phys Technol 108:103337. https://doi.org/10.1016/j.infrared.2020.103337

Dupont F, Stoukatch S, Laurent P, Dricot S, Kraft M (2018) 355 nm UV laser patterning and post-processing of FR4 PCB for fine pitch components integration. Opt Lasers Eng 100:186–194. https://doi.org/10.1016/j.optlaseng.2017.08.014

Zhang Y, Gao X, Katayama S (2015) Weld appearance prediction with BP neural network improved by genetic algorithm during disk laser welding. J Manuf Syst 34:53–59. https://doi.org/10.1016/j.jmsy.2014.10.005

Ding H, Wang Z, Guo Y, Yin X (2020) Research on laser processing technology of instrument panel implicit weakening line based on neural network and genetic algorithm. Optik 203:163970. https://doi.org/10.1016/j.ijleo.2019.163970

Jamali B, Rasekh M, Jamadi F, Gandomkar R, Makiabadi F (2019) Using PSO-GA algorithm for training artificial neural network to forecast solar space heating system parameters. Appl Therm Eng 147:647–660. https://doi.org/10.1016/j.applthermaleng.2018.10.070

Ruan X, Zhu Y, Li J, Cheng Y (2020) Predicting the citation counts of individual papers via a BP neural network. J Informet 14(3):101039. https://doi.org/10.1016/j.joi.2020.101039

Funding

This work was supported by the construction of machine tools and equipment CNC interconnection platform and big data center and application platform (grant no. 2021–0171-1–1).

Author information

Authors and Affiliations

Contributions

Xingfei Ren and Jinwei Fan provided the ideas for this study and wrote the code and the manuscript. Ri Pan assisted in revising the manuscript and code. Kun Sun provided support and assistance in conducting the experiments. All authors contributed to this study.

Corresponding author

Ethics declarations

Ethics approval

The research does not involve ethical issues.

Consent for publication

All the authors agreed to publish this paper.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ren, X., Fan, J., Pan, R. et al. Modeling and process parameter optimization of laser cutting based on artificial neural network and intelligent optimization algorithm. Int J Adv Manuf Technol 127, 1177–1188 (2023). https://doi.org/10.1007/s00170-023-11543-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11543-6