Abstract

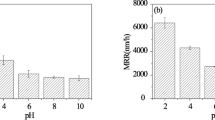

Aiming at these problems of low efficiency, high cost, and environmental pollution in the chemical mechanical polishing (CMP) process of single crystal SiC substrates, a dry-type tribochemical mechanical polishing (DTCMP) method was proposed, and catalysts were added to enhance its efficiency, and the mechanism of catalyst action was investigated. In this study, different contents of nanocatalysts Fe2O3 and Fe3O4 were added to the DTCMP experiments on 6H-SiC substrates, and the material removal characteristics of SiC substrates were investigated under different polishing pressures and rotational speeds with different types of catalysts. Surface morphology, hardness change, surface elements, and crystalline structure of SiC before and after the polishing were analyzed using white light interferometer, nanoindenter, scanning electron microscopes, and X-ray diffractometer. The results show that the catalytic performance of the Fe3O4 catalyst was superior to that of the Fe2O3 catalyst and that the Fe3O4 catalyst can catalyze the production of more ·OH from Na2CO3-1.5H2O2 during the assisted polishing process. The material removal rate (MRR) was higher with the addition of catalyst than without, with MRR as high as 709.2 nm/h and surface roughness as low as 2.257 nm. Based on previous research results, this DTCMP achieves higher MRR compared with traditional CMP. In addition, the catalyst can promote the oxidation reaction on the SiC surface, accelerate the generation of surface oxide films, and thus reduce the surface hardness. Catalyst-assisted DTCMP exhibits superior performance in terms of efficiency, cost-effectiveness, and environmental sustainability, which can be an efficient method for preparing ultra-smooth SiC semiconductor materials and may inspire new ideas for their high-efficiency production.

Similar content being viewed by others

References

Goel S (2014) The current understanding on the diamond machining of silicon carbide. J Phys D Appl Phys 47(24):243001. https://doi.org/10.1088/0022-3727/47/24/243001

Cui J, Zhang Z, Liu D, Zhang D, Hu W, Zou L, Lu Y, Zhang C, Lu H, Tang C, Jiang N, Parkin IP, Guo D (2019) Unprecedented piezoresistance Coefficient in Strained silicon carbide. Nano Lett 19(9):6569–6576. https://doi.org/10.1021/acs.nanolett.9b02821

Kimoto T, Cooper JA (2014) Fundamentals of silicon carbide technology: growth, characterization, devices and applications. John Wiley & Sons

Uneda M, Fujii K (2020) Highly efficient chemical mechanical polishing method for SiC substrates using enhanced slurry containing bubbles of ozone gas. Precis Eng 64:91–97. https://doi.org/10.1016/j.precisioneng.2020.03.015

Zhang Y, Chen H, Liu D, Deng H (2020) High efficient polishing of sliced 4H-SiC (0001) by molten KOH etching. Appl Surf Sci 514:145957. https://doi.org/10.1016/j.apsusc.2020.146532

Zhang P, Yang JF, Li L (2020) Trajectory uniformity of the double-sided mechanical polishing of SiC single crystal substrate. Mat Sci Semicon Proc 107:104814. https://doi.org/10.1016/j.mssp.2019.104814

Deng H, Endo K, Yamamura K (2017) Damage-free finishing of CVD-SiC by a combination of dry plasma etching and plasma-assisted polishing. Int J Mach Tool Manu 115:38–46. https://doi.org/10.1016/j.ijmachtools.2016.11.002

Zhang LF, Deng H (2020) Highly efficient and damage-free polishing of GaN (0001) by electrochemical etching-enhanced CMP process. Appl Surf Sci 514:145957. https://doi.org/10.1016/j.apsusc.2020.145957

Yuan ZW, He Y, Sun XW, Wen Q (2017) UV-TiO2 photocatalysis-assisted chemical mechanical polishing 4H-SiC wafer. Mater Manuf Process 33(11):1214–1222. https://doi.org/10.1080/10426914.2017.1364855

Deng J, Lu J, Zeng S, Xiong Q, Yan Q, Pan J (2022) Preparation and processing properties of magnetically controlled abrasive solidification orientation—solid-phase Fenton reaction lapping-polishing plate for single-crystal 4H-SiC. Surf Interfaces 29:101646. https://doi.org/10.1016/j.surfin.2021.101646

Qian C, Fan Z, Tian Y, Liu Y, Han J, Wang J (2021) A review on magnetic abrasive finishing. Int J Adv Manuf Tech 112:619–634. https://doi.org/10.1007/s00170-020-06363-x

Ma GL, Li SJ, Liu FL, Zhang C, Jia Z, Yin XC (2022) A review on precision polishing technology of single-crystal SiC. Crystals 12(1):101. https://doi.org/10.3390/cryst12010101

Hsieh CH, Chang CY, Hsiao YK, Chen CA, Tu CC, Kuo HC (2022) Recent advances in silicon carbide chemical mechanical polishing technologies. Micromachines (Basel) 13(10):1752. https://doi.org/10.3390/mi13101752

Zantye PB, Kumar A, Sikder AK (2004) Chemical mechanical planarization for microelectronics applications. Mat Sci Eng R 45(3–6):89–220. https://doi.org/10.1016/j.mser.2004.06.002

Lee H, Kim H, Jeong H (2021) Approaches to sustainability in chemical mechanical polishing (CMP): a review. Int J Pr Eng Man-GT 9(1):349–367. https://doi.org/10.1007/s40684-021-00406-8

Zhang ZY, Liu J, Hu W, Zhang LZ, Xie WX, Liao LX (2021) Chemical mechanical polishing for sapphire wafers using a developed slurry. J Manuf Process 62:762–771. https://doi.org/10.1016/j.jmapro.2021.01.004

Lin YC, Kao CH (2004) A study on surface polishing of SiC with a tribochemical reaction mechanism. Int J Adv Manuf Tech 25(1–2):33–40. https://doi.org/10.1007/s00170-003-1873-x

Muratov VA, Fischer TE (2000) Tribochemical polishing. Annu Rev Mater Sci 30(1):27–51. https://doi.org/10.1146/annurev.matsci.30.1.27

Su JX, X R, W YP, L JJ, L HX (2020) Study on lapping paste of 6H–SiC single-crystal substrate in tribochemical mechanical lapping. J Inst Eng (India): Series E 101(2):141-148. https://doi.org/10.1007/s40034-020-00167-0

Yuan S, Guo X, Lu M, Jin Z, Kang R, Guo D (2019) Diamond nanoscale surface processing and tribochemical wear mechanism. Diam Relat Mater 94:8–13. https://doi.org/10.1016/j.diamond.2019.02.012

Rogov VV, Rublev ND, Krotenko TL, Troyan AV (2008) A study of intensity of tribochemical contact interaction between a polishing compound and sapphire in machining. J Superhard Mater 30(4):273–275. https://doi.org/10.3103/S1063457608040072

Chen JP, Peng YA, Wang ZK, Sun T, Su JX, Zuo DW, Zhu YW (2022) Tribological effects of loose alumina abrasive assisted sapphire lapping by a fixed agglomerated diamond abrasive pad (FADAP). Mat Sci Semicon Proc 143:106556. https://doi.org/10.1016/j.mssp.2022.106556

Chen J, Sun T, Su J, Li J, Zhou P, Peng Y, Zhu Y (2021) A novel agglomerated diamond abrasive with excellent micro-cutting and self-sharpening capabilities in fixed abrasive lapping processes. Wear 464–465. https://doi.org/10.1016/j.wear.2020.203531

Zhou Y, Pan GS, Shi XL, Gong H, Luo GH, Gu ZH (2014) Chemical mechanical planarization (CMP) of on-axis Si-face SiC wafer using catalyst nanoparticles in slurry. Surf Coat Tech 251:48–55. https://doi.org/10.1016/j.surfcoat.2014.03.044

Zhang P, Chen G, Ni Z, Wang Y, Teng K, Qian S, Bian D, Zhao Y (2021) The effect of Cu2+ ions and glycine complex on chemical mechanical polishing (CMP) Performance of SiC substrates. Tribol Lett 69(3):1–10. https://doi.org/10.1007/s11249-021-01468-0

Xu SP, Lu JB, Yan QS, Song T, Pan JS (2017) Solid catalysts based on fenton reaction for sic wafer in chemical mechanical polishing. J Mech Eng 53(21). https://doi.org/10.3901/jme.2017.21.167

Deng H, Liu N, Endo K, Yamamura K (2018) Atomic-scale finishing of carbon face of single crystal SiC by combination of thermal oxidation pretreatment and slurry polishing. Appl Surf Sci 434:40–48. https://doi.org/10.1016/j.apsusc.2017.10.159

Saitoh Y, Itoh H, Wada K, Sakai M, Horii T, Hiratsuka K, Tanaka S, Mikamura Y (2016) 150 A SiC V-groove trench gate MOSFET with 6× 6 mm2 chip size on a 150 mm C-face in-house epitaxial wafer. Jpn J Appl Phys 55(4S):04ER05. https://doi.org/10.7567/JJAP.55.04ER05

Wang X, Chen J, Bu Z, Wang H, Wang W, Li W, Sun T (2021) Accelerated C-face polishing of silicon carbide by alkaline polishing slurries with Fe3O4 catalysts. J Environ Chem Eng 9(6):106863. https://doi.org/10.1016/j.jece.2021.106863

Liu X, He S, Yang Y, Yao B, Tang Y, Luo L, Zhi D, Wan Z, Wang L, Zhou Y (2021) A review on percarbonate-based advanced oxidation processes for remediation of organic compounds in water. Environ Res 200:111371. https://doi.org/10.1016/j.envres.2021.111371

Zhang BT, Kuang LL, Teng YG, Fan MH, Ma Y (2021) Application of percarbonate and peroxymonocarbonate in decontamination technologies. J Environ Sci 105:100–115. https://doi.org/10.1016/j.jes.2020.12.031

Qi W, Cao X, Xiao W, Wang Z, Su J (2021) Study on the mechanism of solid-Phase oxidant action in tribochemical mechanical polishing of SiC single crystal substrate. Micromachines (Basel) 12(12):1547. https://doi.org/10.3390/mi12121547

Wada T, Nakano M, Koga N (2015) Multistep kinetic behavior of the thermal decomposition of granular sodium percarbonate: hindrance effect of the outer surface layer. J Phys Chem A 119(38):9749–9760. https://doi.org/10.1021/acs.jpca.5b07042

Pan G, Zhou Y, Luo G, Shi X, Zou C, Gong H (2013) Chemical mechanical polishing (CMP) of on-axis Si-face 6H-SiC wafer for obtaining atomically flat defect-free surface. J Mater Sci-Mater El 24(12):5040–5047. https://doi.org/10.1007/s10854-013-1519-1

Liu B, Zhan Y, Xie R, Huang H, Li K, Zeng Y, Shrestha RP, Kim Oanh NT, Winijkul E (2019) Efficient photocatalytic oxidation of gaseous toluene in a bubbling reactor of water. Chemosphere 233:754–761. https://doi.org/10.1016/j.chemosphere.2019.06.002

Yin T, Zhao P, Doi T, Kurokawa S, Jiang J (2021) Effect of using high-pressure gas atmosphere with UV photocatalysis on the CMP characteristics of a 4H-SiC substrate. ECS J Solid State Sc Technol. 10(2):024010. https://doi.org/10.1149/2162-8777/abe7a8

Poddar MK, Ryu HY, Yerriboina NP, Jeong Y-A, Lee JH, Kim TG, Kim JH, Park JD, Lee MG, Park CY, Han SJ, Choi JG, Park JG (2019) Nanocatalyst-induced hydroxyl radical (·OH) slurry for tungsten CMP for next-generation semiconductor processing. J Mater Sci 55(8):3450–3461. https://doi.org/10.1007/s10853-019-04239-4

Hariharaputhiran M, Zhang J, Ramarajan S, Keleher JJ, Li Y, Babu SV (2000) Hydroxyl radical formation in H2O2 - amino acid mixtures and chemical mechanical polishing of copper. J Electrochem Soc 147(10):3820–3826. https://doi.org/10.1149/1.1393979

Chen CQ, Ren HJ, Zhou JK, Luo Y, Zhan YY, Au CT, Lin XY, Jiang LL (2020) Cu/Fe3O4 catalyst for water gas shift reaction: insight into the effect of Fe2+ and Fe3+ distribution in Fe3O4. Int J Hydrogen Energ 45(15):8456–8465. https://doi.org/10.1016/j.ijhydene.2020.01.023

Kubota A, Yoshimura M, Fukuyama S, Iwamoto C, Touge M (2012) Planarization of C-face 4H-SiC substrate using Fe particles and hydrogen peroxide solution. Precis Eng 36(1):137–140. https://doi.org/10.1016/j.precisioneng.2011.09.003

Oh S, Seok J (2008) Modeling of chemical–mechanical polishing considering thermal coupling effects. Microelectron Eng 85(11):2191–2201. https://doi.org/10.1016/j.mee.2008.04.037

Wang W, Zhang B, Shi Y, Zhou D, Wang R (2022) Improvement in dispersion stability of alumina suspensions and corresponding chemical mechanical polishing performance. Appl Surf Sci 597:153703. https://doi.org/10.1016/j.apsusc.2022.153703

Presser V, Krummhauer O, Nickel KG, Kailer A, Berthold C, Raisch C (2009) Tribological and hydrothermal behaviour of silicon carbide under water lubrication. Wear 266(7–8):771–781. https://doi.org/10.1016/j.wear.2008.10.001

Hornetz B, Michel HJ, Halbritter J (1994) ARXPS studies of SiO2-SiC interfaces and oxidation of 6H-SiC single crystal Si-(001) and C-(001) surfaces. J Mater Res 9(12):3088–3094. https://doi.org/10.1557/JMR.1994.3088

Wang W, Zhang B, Shi Y, Zhou J, Wang R, Zeng N (2022) Improved chemical mechanical polishing performance in 4H-SiC substrate by combining novel mixed abrasive slurry and photocatalytic effect. Appl Surf Sci 575:151676. https://doi.org/10.1016/j.apsusc.2021.151676

Chen JP, Zhu YW, Peng YA, Guo JT, Ding C (2020) Silica-assisted fixed agglomerated diamond abrasive polishing. J Manuf Processes 59:595–603. https://doi.org/10.1016/j.jmapro.2020.09.013

Yuan Z, He Y, Jin Z, Zheng P, Li Q (2017) Prediction of the interface temperature rise in tribochemical polishing of CVD diamond. Chin J Mech Eng-en 30(2):310–320. https://doi.org/10.1007/s10033-017-0087-3

Kuhlmann-Wilsdorf D (1985) Flash temperatures due to friction and Joule heat at asperity contacts. Wear 105(3):187–198. https://doi.org/10.1016/0043-1648(85)90067-5

Lipkin L, Palmour J (1996) Improved oxidation procedures for reduced SiO2/SiC defects. J Electron Mater 25:909–915. https://doi.org/10.1007/BF02666657

Liu GL, Huang ZR, Liu XJ, Jiang DL (2010) Removal Behaviors of different SiC ceramics during polishing. J Mater Sci Technol 26(2):125–130. https://doi.org/10.1016/S1005-0302(10)60020-5

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. U1804142) and the Science and Technology Research Project of Henan Province (Grant No.192102210058).

Author information

Authors and Affiliations

Contributions

Mingpu Xue: investigation, data curation, and writing—original draft preparation. Wen Xiao: investigation and resources. Tianyi Zhang: investigation. Zhankui Wang: supervision and funding acquisition. Jianxiu Su: conceptualization, methodology, validation, and writing—review & editing, supervision, project administration, and funding acquisition. The authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare have no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xue, M., Xiao, W., Zhang, T. et al. Catalytic mechanism of tribochemical mechanical polishing on (0001) C-face of single crystal 6H-SiC substrate. Int J Adv Manuf Technol 131, 2311–2323 (2024). https://doi.org/10.1007/s00170-023-11494-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11494-y