Abstract

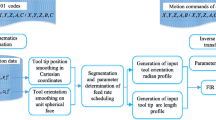

Five-axis linear commands are blended as the local smoothed toolpaths by inserting clothoid and airthoid splines at corners in five-axis CNC machining. The contour error is the bottleneck to achieve the precise dimension of the machined parts, when following the local smoothed toolpaths. This paper presents a contour error estimation and control method for the five-axis smoothed toolpaths with airthoid splines, according to the geometric characteristics of the toolpaths. The tool-tip contour error is analytically calculated based on the expression of the smoothed toolpaths. Consequently, the tool-orientation contour error is obtained by synchronizing the tool-orientation contour point with the tool-tip item based on the motion time through the designed time scale coefficient, when the toolpaths are scheduled by the time-synchronization scheme. Furthermore, a contour error compensation strategy is constructed to adaptively determine the compensator gain. It can be qualified to maximally eliminate the contour errors and steadily hold the control stability of the feed drives, in spite of the modeling error between the nominal and actual control models. The simulation and experiment results show that the estimation algorithm has higher accuracy than traditional methods, and the compensation strategy effectively eliminates the five-axis contour error.

Similar content being viewed by others

References

Li XF, Huang T, Zhao H et al (2022) A review of recent advances in machining techniques of complex surfaces. Sci China Tech Sci 65:1915–1939. https://doi.org/10.1007/s11431-022-2115-x

Lyu D, Liu Q, Luo SY, Wang DW, Liu H et al (2021) The influence of dynamic error outside servo-loop on the trajectory error. Int J Advan Manuf Techn 113:1517–1525. https://doi.org/10.1007/s00170-021-06668-5

Huang XY, Zhao F, Mei XS et al (2019) A novel triple-stage friction compensation for a feed system based on electromechanical characteristics. Prec Eng 56:113–122. https://doi.org/10.1016/j.precisioneng.2018.11.006

Kaan E, Altintas Y (1998) High speed contouring control algorithm for CNC machine tools. Proc ASME Dyn Syst Contr Div 463–469. https://doi.org/10.1115/IMECE1998-0290

Cheng MY, Lee CC (2007) Motion controller design for contour-following tasks based on real-time contour error estimation. IEEE Trans on Industr Elec 54(3):1686–1695. https://doi.org/10.1109/TIE.2007.894691

Huo F, Poo AN (2012) Improving contouring accuracy by using generalized cross-coupled control. Int J Mach Tool Manuf 63:49–57. https://doi.org/10.1016/j.ijmachtools.2012.07.012

Yang JZ, Li ZX (2010) A novel contour error estimation for position loop-based cross-coupled control. IEEE/ASME Trans Mech 16(4):643–655. https://doi.org/10.1109/TMECH.2010.2048718

Yao B, Hu CX, Wang QF (2012) An orthogonal global task coordinate frame for contouring control of biaxial system. IEEE/ASME Trans Mech 17(4):622–634. https://doi.org/10.1109/TMECH.2011.2111377

Zhu LM, Zhao H, Ding H (2013) Real-time contouring error estimation for multi-axis motion systems using the second-order approximation. Int J Mach Tool Manuf 68:75–80. https://doi.org/10.1016/j.ijmachtools.2013.01.008

Wang Z, Hu CX, Zhu Y et al (2018) Newton-ILC contouring error estimation and coordinated motion control for precision multiaxis systems with comparative experiments. IEEE Trans Ind Electron 65(2):1470–1480. https://doi.org/10.1109/TIE.2017.2733455

Song DN, Zhong YG, Ma JW (2019) Third-order contour-error estimation for arbitrary free-form paths in contourfollowing tasks. Prec Eng 60:85–92. https://doi.org/10.1016/j.precisioneng.2019.07.009

Khalick M, Naoki U (2013) Estimation of tool orientation contour errors for five-axismachining. Rob Comp Int Manuf 29(5):271–277. https://doi.org/10.1016/j.rcim.2013.01.002

Yang JX, Altintas Y (2015) A generalized on-line estimation and control of five-axis contouring errors of CNC machine tools. Int J Mach Tools Manuf 88:9–23. https://doi.org/10.1016/j.ijmachtools.2014.08.004

Li XF, Zhao H, Zhao X et al (2018) Interpolation-based contour error estimation and component-based contouring control for five-axis CNC machine tools. Sci China Tech Sci 61:1666–1678. https://doi.org/10.1007/s11431-017-9204-y

Pi SW, Liu Q, Liu QT (2018) A novel dynamic contour error estimation and control in high-speed CNC. Int J Advan Manuf Techn 96(1):547–560. https://doi.org/10.1007/s00170-018-1629-2

Yang M, Yang J, Ding H (2018) A high accuracy on-line estimation algorithm of five-axis contouring errors based on three-point arc approximation. Int J Mach Tool Manuf 130:73–84. https://doi.org/10.1016/j.ijmachtools.2018.04.001

Yang M, Yang J, Zhu LM (2020) A novel curvature circle iterative algorithm for contour error control of multi-axis CNC machine tools. Prec Eng 65:23–31. https://doi.org/10.1016/j.precisioneng.2020.05.005

Yuen A, Zhang K, Altintas Y (2013) Smooth trajectory generation for five-axis machine tools. Int J Mach Tool Manuf 71:11–19. https://doi.org/10.1016/j.ijmachtools.2013.04.002

Sun YW, Zhao Y, Xu JT et al (2014) The feedrate scheduling of parametric interpolator with geometry, process and drive constraints for multi-axis CNC machine tools. Int J Mach Tool Manuf 85:49–57. https://doi.org/10.1016/j.ijmachtools.2014.05.001

Nurnberg, Siemens AG (2017) SINUMERIK 840D sl/828D Fundamentals: Programming Manual

Yamanashi, Fanuc Corporation (2017) Nano CNC for High-Speed, High-Accuracy machining

Li XF, Zhao H, Zhao X et al (2016) Dual sliding mode contouring control with high accuracy contour error estimation for five-axis CNC machine tools. Int J Mach Tool Manuf 108:74–82. https://doi.org/10.1016/j.ijmachtools.2016.05.007

Jia ZY, Song DN, Ma JW et al (2018) High-precision estimation and double-loop compensation of contouring errors in five-axis dual-NURBS toolpath following tasks. Prec Eng 54:243–253. https://doi.org/10.1016/j.precisioneng.2018.06.001

Liu Y, Wan M, Xiao QB, Qin XB (2022) Combined predictive and feedback contour error control with dynamic contour error estimation for industrial five-axis machine tools. IEEE Trans Ind Elec 69:6668–6677. https://doi.org/10.1109/TIE.2021.3097659

Yang J, Yuen A (2017) An analytical local corner smoothing algorithm for five-axis CNC machining. Int J Mach Tool Manuf 123:22–35. https://doi.org/10.1016/j.ijmachtools.2017.07.007

Wan M, Qin XB, Xiao QB et al (2021) Asymmetrical pythagorean-hodograph (PH) spline-based C3 continuous corner smoothing algorithm for five-axis tool paths with short segments. J Manuf Proc 64:1387–1411. https://doi.org/10.1016/j.jmapro.2021.02.059

Sun SJ, Altintas Y (2021) A G3 continuous tool path smoothing method for 5-axis CNC machining. CIRP J Manuf Sci Techn 32:529–549. https://doi.org/10.1016/j.cirpj.2020.11.002

Yang JX, Li DW, Ye CC, Ding H (2022) An analytical C3 continuous tool path corner smoothing algorithm for 6R robot manipulator. Rob Comp Int Manuf 64:101947. https://doi.org/10.1016/j.rcim.2020.101947

Hu Q, Chen YP, Yang JX (2020) On-line contour error estimation and control for corner smoothed five-axis tool paths. Int J Mech Sci 171:105377. https://doi.org/10.1016/j.ijmecsci.2019.105377

Jiang Y, Han J, Huang XY, Tao TJ (2022) An on-line contour error estimation and compensation strategy for five-axis local smoothed trajectory under motion time synchronization. Int J Mach Tool Manuf 120:3451–3469. https://doi.org/10.1007/s00170-022-08797-x

Shahzadeh A, Khosravi A, Robinette T et al (2018) Smooth path planning using biclothoid fillets for high speed CNC machines. Int J Mach Tool Manuf 132:36–49. https://doi.org/10.1016/j.ijmachtools.2018.04.003

Xiao QB, Wan M, Liu Y et al (2020) Space corner smoothing of CNC machine tools through developing 3D general clothoid. Rob Comp Int Manuf 64:101949. https://doi.org/10.1016/j.rcim.2020.101949

Huang XY, Zhao F, Tao T et al (2021) A newly developed corner smoothing methodology based on clothoid splines for high speed machine tools. Rob Comp Int Manuf 70:102106. https://doi.org/10.1016/j.rcim.2020.102106

Huang XY, Zhao F, Tao T et al (2020) A novel local smoothing method for five-axis machining with time-synchronization feedrate scheduling. IEEE Acc 8:89185–89204. https://doi.org/10.1109/ACCESS.2020.2992022

Zhang DL, Chen YH, Chen YP (2016) Iterative pre-compensation scheme of tracking error for contouring error reduction. Int J Advan Manuf Techn 87(9):3279–3288. https://doi.org/10.1007/s00170-016-8735-9

Tan SZ, Yang JX, Ding H (2023) A Prediction and Compensation Method of Robot Tracking Error Considering Pose-dependent Load Decomposition. Rob Comp Int Manuf 80:102476. https://doi.org/10.1016/j.rcim.2022.102476

Liu RW, Ren F, Sun YW, Jiang SL (2018) Contour error precompensation for three-axis machine tools by using cross-coupled dynamic friction control. Int J Adv Manuf Technol 98:551–563. https://doi.org/10.1007/s00170-018-2189-1

Wan M, Xiao QB, Liu Y, Zhang WH (2020) A new decoupled tangential contouring control scheme for multi-dimensional motion. Mech Mach Theor 151:103944. https://doi.org/10.1016/j.mechmachtheory.2020.103944

Du X, Huang J, Zhu LM et al (2020) Sliding mode control with third-order contour error estimation for free-form contour following. Prec Eng 66:282–294. https://doi.org/10.1016/j.precisioneng.2020.06.015

Zhang K, Yuen A, Altintas Y (2013) Pre-compensation of contour errors in five-axis CNC machine tools. J Mach Tool Manuf 74:1–11. https://doi.org/10.1016/j.ijmachtools.2013.07.003

Wang Z, Hu CX, Zhu Y (2019) Dynamical model based contouring error position-loop feedforward control for multiaxis motion systems. IEEE Trans Ind Inf 15(8):4686–4695. https://doi.org/10.1109/TII.2019.2895071

Jia ZY, Ma JW, Song DN et al (2018) A review of contouring-error reduction method in multi-axis CNC machining. Int J Mach Tool Manuf 125:34–54. https://doi.org/10.1016/j.ijmachtools.2017.10.008

Yeh SS, Hsu PL (1999) Theory and applications of the robust cross-coupled control design. J. Dyn Syst Meas Contr 121(3):524–530. https://doi.org/10.1109/ACC.1997.611911

Alazah M, Chandler-Wilde SN, La Porte S (2014) Computing Fresnel integrals via modified trapezium rules. Num Math 128(4):635–661. https://doi.org/10.1007/s00211-014-0627-z

Liu Y, Wan M, Qin XB et al (2020) FIR filter-based continuous interpolation of G01 commands with bounded axial and tangential kinematics in industrial five-axis machine tools. Int J Mech Sci 169:105325. https://doi.org/10.1016/j.ijmecsci.2019.105325

Feng B, Zhang DS, Mei XS et al (2015) Investigation of the controller parameter optimisation for a servomechanism. Proc I Mech Eng, Part B: J Eng Manuf 229(1):98–110. https://doi.org/10.1177/0954405414558697

Erkorkmaz K, Altintas Y (2001) High speed CNC system design. Part II: modeling and identification of feed drives. J Mach Tool Manuf 41:1487–1509. https://doi.org/10.1016/S0890-6955(01)00003-7

Funding

This work was financially supported by the National Natural Science Foundation of China under Grant nos. 52105512, 52275483, 52075142, the Major Science and Technology Projects of Anhui Province under Grant no.202003a05020033 and the Fundamental Research Funds for the Central Universities under Grant no.JZ2021HGQA0217.

Author information

Authors and Affiliations

Contributions

Xiaoyong Huang: Investigation, Methodology, Writing original draft. Baoqing Chen: Investigation, Validation, Data curation. Xiaoqing Tian: Investigation, Resources, Supervision, Funding acquisition. Shan Chen: Investigation, Validation, Data curation. Daoyang Yu: Investigation, Validation, Data curation. Jiang Han: Project administration, Investigation, Methodology. Xuesong Mei: Project administration, Investigation, Methodology.

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare no competing interests.

Ethical standard

All sources used are properly disclosed. No waivers are applicable for this project.

Consent to participate

All authors have been personally and actively involved in substantial work leading to the paper, and will take public responsibility for its content

Consent for publication

All author(s) and co-authors agreed for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, X., Chen, B., Tian, X. et al. Real-time estimate and control contour errors for five-axis local smoothed toolpaths based on airthoid splines. Int J Adv Manuf Technol 127, 1483–1504 (2023). https://doi.org/10.1007/s00170-023-11363-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11363-8