Abstract

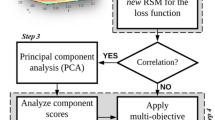

This report presents a methodical approach for enhancing industrial production revenue in TIX cable industry. Taguchi robust design approaches were applied to cable insulation process lines in order to appraise and reset process parameters. L9 (34) orthogonal array was used to design and conduct experiments for measuring the quality characteristics. Minitab17.0 software was used to evaluate the signal-to-noise ratio (SNR) for the optimization of process line machines’ parameters and responses for compounding extrusion and cable insulation process lines. Also, L18 (35) was utilized in the design of experiments for optimal formulation of new insulation compound that would optimize the performance characteristics of the product. The optimal control factor levels that minimized the variabilities in the electrical cable manufacturing process and product were determined and established for TIX industry. In coded units, the compounding extruder parameter setting should be A21B22C23D21, the insulation extruder parameter should be set at BZ1CZ1DZ1 and BZ2CZ1DZ1, and the new insulation compound should be A1B1C1D1E1 for optimal output. The results of this study, when compared with the established standard requirements in electrical cable insulation, met the standards. This shows the importance of Taguchi robust design in optimization of manufacturing processes and products. The findings of this study show that Taguchi robust design is a powerful tool that can improve the product quality, reduce product costs, and achieve significant economic benefits in the manufacturing sector.

Similar content being viewed by others

References

Hicks BJ, Culley SJ (2002) Compatibility issues for mechanical system modelling with standard components. Proc Inst Mech Eng Part B: J Eng Manuf 216(2):235–249

Yusuf YY, Adeleye EO (2002) A comparative study of lean and agile manufacturing with a related survey of current practices in the UK. Int J Prod Res 40(17):4545–4562

Wang W, Koren Y (2012) Scalability planning for reconfigurable manufacturing systems. J Manuf Syst 31:83–91

Plecka P, Bzdyra K (2013) Algorithm of selecting cost estimation methods for ERP software implementation. Appl Comput Sci 9(2):5–19

Gola A (2014) Economical aspects of manufacturing systems design. Actual Problems Econ 156(6):1–9

Aljorephani SK, ElMaraghy HA (2016) Impact of product platform and market demand on manufacturing system performance and production cost. Procedia CIRP 52:74–79

Kemmler S, Fuchs A, Leopold T, Bertsche B (2015) Comparison of Taguchi method and robust design optimization (RDO)-by application of a functional adaptive simulation model for the robust product-optimization of an adjuster unit. 12th Welmar Optimization and Stochastic, Stuttgart

Biron M (2016) Thermoplastics: economic overview. In: Biron M (ed) Material selection for thermoplastic parts. William Andrew Publishing, Oxford, pp 77–111. https://doi.org/10.1016/B978-0-7020-6284-10003-9

Taguchi G (1986) Quality engineering through design optimization. Krauss International Publications White Plains, New York

Ihueze CC, Okafor EC, Ujam AJ (2012) Optimization of tensile strengths response of Plantain fibres reinforced Polyesters composites (PFRP) applying Taguchi robust design. Innov Syst Des Eng 3(7):62–76

Ihueze CC, Okpala CC (2012) Application of Taguchi robust design as optimized lean production system in manufacturing companies. Res J Eng Appl Sci 1(1):45–50

Radhwan H, Rozaimi MS, Raizaidi H, Mohd SIMD (2012) An optimization of plastic injection molding parameters using Taguchi optimization method. Asian Trans Eng 2(2):75–80

Rishi P, Jaiprakash B (2013) Optimization of injection moulding process using Taguchi and ANOVA. Int J Sci Eng Res 4(1):1–5

Jou YT, Lin WT, Lee WC, Yeh TM (2014) Integrating the Taguchi method and response surface methodology for process parameter optimization of the injection molding. Appl Math Inform Sci 8(3):1277–1285

Hamzaçebi C (2016) Optimization of process parameters in oriented strand board manufacturing by Taguchi method. BioResource 11(3):5987–5993

Alafaghani A, Qattawi A (2018) Investigating the effect of fused deposition modeling processing parameters using Taguchi design of experiment method. J Manuf Process 36:164–174

Okpala CC, Ihueze CC (2019) Robust design for optimal setting of process wastes parameters in an automotive parts manufacturing company. Int J Ind Manuf Eng 13(2):101–106

Terzioğlu H (2020) Analysis of effect factors on thermoelectric generator using Taguchi method. Measurement 149:106992

Viswanathan R, Ramesh S, Maniraj S, Subburam V (2020) Measurement and multi-response optimization of turning parameters for magnesium alloy using hybrid combination of Taguchi-GRA-PCA. Measurement 159(5):107800

Goetz S, Roth M, Schleich B (2021) Early robust design – its effect on parameter and tolerance optimization. Appl Sci 11:9407

Armando MC (2021) Robust parameter design and economical multi-objective optimization on characterizing rubber for shoe soles. DYNA 88(216):160–169

Ihueze CC, Obiuto CC, Okafor CE, Okpala CC (2013) Orthogonal array application and response surface method approach for optimal product values: an application for Oil blending process. World Acad Sci Eng Technol 76:558–562

Behera SK, Meena H, Chakraborty S, Meikap BC (2018) Application of response surface methodology (RSM) for optimization of leaching parameters for ash reduction from low-grade coal. Int J Min Sci Technol 28(4):621–629

Agrawal S, Gaur MK, Kasdekar DK, Agrawal S (2018) Optimization of machining parameters of hard porcelain on a CNC machine by Taguchi-and RSM method. Int J Eng Sci Technol 10(1):13–22

Abubakar IK, Ibrahim A, Muhammad YY (2021) Optimization of biogas production from cow dung using response surface methodology. Asian J Res Biosci 3(2):14–20

Elganidi I, Elarbe B, Ridzuan N, Abdullah N (2022) Optimization of reaction parameters for novel polymeric additives as flow improvers of crude oil using response surface methodology. J Pet Explor Prod Technol 12:437–449

Choudhary AK, Pramanik H (2021) Optimization and validation of process parameters via RSM for minimizing use of resources to generate electricity from a DEFC. Int J Energy Res 45(14):20413–20429

Nguyen V, Altarazi F, Tran T (2022) Optimization of process parameters for laser cutting process of stainless steel 304: a comparative analysis and estimation with Taguchi method and response surface methodology. Math Problems Eng ID6677586. https://doi.org/10.1155/2022/6677586.

Razaviye MK, Tafti RA, Khajehmohammadi M (2022) An investigation on mechanical properties of PA12 parts produced by a SLS 3D printer: an experimental approach. CIRP J Manuf Sci Technol 38:760–768. https://doi.org/10.1016/j.cirpj.2022.06.016

Kuma L, Kumar K, Chhabra D (2022) Experimental investigations of electrical discharge micro-drilling for Mg-alloy and multi-response optimization using MOGA-ANN. CIRP J Manuf Sci Technol 38:774–786. https://doi.org/10.1016/j.cirpj.2022.06.014

Ihueze CC, Okpala CC (2014) The tools and techniques of lean production system of manufacturing. Int J Adv Eng Technol 5(4):22–27

Ihueze CC, Okpala CC (2011) A survey of optimum manufacturing strategy as a tool for enhanced industrial revenue. Aust J Basic Appl Sci 5(12):1321–1329

Okpala CC, Ihueze CC (2017) Ergonomics improvements in a paint manufacturing company. Int Res J Eng Technol 4(17):1985–1993

Alejandro AI, Jorge LGA, Manual IRB (2013) Optimization of injection molding process parameters by a hybrid of artificial Bee colony algorithm. Rev Fac Ing Univ Antioquia 67:43–51

Jamalian HM, Eskander MT, Chamanara A, Karimzadeh R, Yousefian R (2021) An artificial neural network model for multi-pass tool pin varying FSW of AA5086-H34 plates reinforced with Al2O3 nanoparticles and optimization for tool design insight. CIRP J Manuf Sci Technol 35:69–79. https://doi.org/10.1016/j.cirpj.2021.05.007

Krishna PR, Veena NR, Preeti S, Nando GB (2010) Optimization of processing parameters for a Polymer blend using Taguchi method. Yambu J Eng Sci 1:

Załuski D, Stolarski MJ, Krzyżaniak M (2022) Validation of the Taguchi method on the example of evaluation of willow biomass production factors under environmental stress. Ind Crops Prod 185:115170

Park SH (1996) Robust design and analysis for quality engineering. Chapman and Hall, London

Yang S, Wang J, Tu Y (2022) Bayesian robust parameter design for ordered response. Int J Prod Res 60(12):3630–3650

Hasanzadeh R, Mojaver P, Chitsaz A, Mojaver M, Jalili M, Rosen MA (2022) Biomass and low-density polyethylene waste composites gasification: orthogonal array design of Taguchi technique for analysis and optimization. Int J Hydrogen Energy 47(67):28819–28832

Hamzaçebi C (2020) Taguchi method as a robust design tool [Online]. Accessed on 8 August 2022, from https://www.researchgate.net/publication/347858318

Phadke MS (1989) Quality Engineering using Robust Design. Prentice-Hall, Englewood Cliffs

Usman Jan QM, Habib T, Noor S, Abas M, Azim S, Yaseen QM (2020) Multi response optimization of injection moulding process parameters of polystyrene and polypropylene to minimize surface roughness and shrinkage’s using integrated approach of S/N ratio and composite desirability function. Cogent Eng 7(1):1781424

Kurnia JC, Haryoko LA, Taufiqurrahman I, Chen L, Jiang L, Sasmito AP (2022) Optimization of an innovative hybrid thermal energy storage with phase change material (PCM) wall insulator utilizing Taguchi method. J Energy Storage 49:104067

Gu YP, Cheng LS, Xu LJ, Chen XL (2019) Optimization of cable insulation eccentricity by Taguchi robust design. J Ind Prod Eng 36(5):271–275

Krishnaiah K, Shahabudeen P (2012) Applied design of experiments and Taguchi methods. PHI Learning Private Ltd, New Delhi

Hussein R, MohdSaad R, Hussin R, MohdDawi MSI (2012) An optimization of plastic injection molding parameters using Taguchi optimization method. Asian Trans Eng 2(5):75–80

Dieter GE (2000) Materials and processing approach engineering design, 3rd edn. Mc Graw-Hill Informational, Singapore

Ihueze CC, Okoli NC, Onwurah UO, Okafor EC, Kingsley-Omoyibo QA (2023) Intelligent assessment of quality characteristics of miscanthus fiber reinforced polypropylene for sustainable products development. J Process Mech Eng. https://doi.org/10.1177/09544089231167761

Radharamanan R, Ansuj AP (2001) Quality improvement of a production process using Taguchi methods. Proceedings of Institute of Industrial Engineers Annual conference, Dallas, pp 20–22

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Christopher Chukwutoo Ihueze, Uchendu Onwusoronye Onwurah, Nnaemeka Sylvester Obuka, Ndubuisi Celestine Okoli, Constance Obiuto Nwankwo, Charles Chikwendu Okpala, Christian Emeka Okafor, and Adesuwa Kingsley-Omoyibo. The first draft was written by Onwurah Uchendu Onwusoronye and Ihueze Christopher Chukwutoo and all the authors commented on previous versions of the manuscript. All the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ihueze, C.C., Onwurah, U.O., Okafor, C.E. et al. Robust design and setting process and material parameters for electrical cable insulation. Int J Adv Manuf Technol 126, 3887–3904 (2023). https://doi.org/10.1007/s00170-023-11359-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11359-4