Abstract

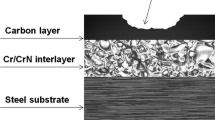

Diamond-like carbon (DLC) coatings have gained wide attraction, due to ultra-low coefficient of friction, high resistance to wear, excellent mechanical properties, and inert to chemical substance, especially in the automobile industry in the last decade. However, a lot of research is still carried out to improve the adhesion properties of DLC coatings to metallic substrate to prevent debonding caused mostly by high internal compressive stress and the difference in thermal expansivity between the metallic substrate and the DLC coatings. Consequently, to improve the adhesion of DLC coatings on metallic substrate, the use of interlayers (Si, SiH and Cr, CrN, Ti and TiN) and metallic (Mo, Ti, Cr, and W) and non-metallic (Si, N, and F) doping elements has been put to use. The interlayers form a transition layer between the metallic substrate and the DLC coating, thereby reducing the thermal expansivity between the metallic substrate and the DLC coatings. On the other hand, the metallic and non-metallic doping elements help in reducing the internal compressive stress in the DLC coatings. The present review article focuses mainly on the deposition techniques, characterisation techniques, and improvement of the adhesion properties of DLC coatings on metallic substrates. It showcases Cr-based interlayers and W/WC dopants as an efficient way to improve adhesion properties of DLC coatings for tribological and tribo-corrosion application in the automobile industry.

Similar content being viewed by others

Data availability

Not applicable.

References

Renub research. Global Automotive Market, Growth & Forecast, September (2021): https://www.researchandmarkets.com/reports/5447681/global-automotive-market-growth-and-forecast. Accessed 30 May 2022

Wood R (2007) Tribo-corrosion of coatings: a review. J Phys D: Appl Phys 40:5502

Kolawole FO, Kolawole SK, Varela LB, Owa AF, Ramirez MA, Tschiptschin AP (2020) Diamond-like carbon (DLC) coatings for automobile applications. In: Mallik A (eds) Engineering applications of diamond, 1st edn. IntechOpen, London, 1–19 https://doi.org/10.5772/intechopen.95063

Gangopadhyay A (2015) Coating technologies for automotive engine applications. In: Cha S, Erdemir A (eds) Coating technology for vehicle applications. Springer, Cham. https://doi.org/10.1007/978-3-319-14771-0_4

Schamel A, Grischke M, Bethke R (1997) Amorphous carbon coatings for low friction and wear in bucket tappet valve trains. Stroke 2015:06–22

Sánchez Egea AJ et al (2019) Friction capabilities of graphite-based lubricants at room and over 1400 K temperatures. Int J Adv Manuf Technol 102:1623–1633. https://doi.org/10.1007/s00170-019-03290-4

Tyagia A, Waliaa RS, Murtazaa Q, Pandeya SM, Tyagib PK, Bajaj B (2019) A critical review of diamond like carbon coating for wear resistance applications. Int J Refract Met and Hard Mater 78:107–122. https://doi.org/10.1016/j.ijrmhm.2018.09.006

Kinoshita H, Ippei I, Sakai H, Ohmae N (2007) Synthesis and mechanical properties of carbon nanotube/diamond-like carbon composite films. Diam Relat Mater 16(11):1940–1944. https://doi.org/10.1016/j.diamond.2007.08.004

Bewilogua K, Hofmann D (2014) History of diamond-like carbon films — from first experiments to worldwide applications. Surf Coat Technol 242:214–225. https://doi.org/10.1016/j.surfcoat.2014.01.031

Oksanen J, Hakala TJ, Tervakangas S, Laakso P, Kilpi L, Ronkainen H, Koskinen J (2014) Tribological properties of laser textured and ta-C coated surfaces with burnished WS2 at elevated temperatures. Tribol Int 70:94–103. https://doi.org/10.1016/j.triboint.2013.09.005

Kousaka DX, Tokoroyama H, Umehara T (2014) Tribological behavior of tetrahedral amorphous carbon (ta-C) coatings at elevated temperatures. Tribol Int 75:98–103. https://doi.org/10.1016/j.triboint.2014.04.002

Tasdemir H, Wakayama M, Tokoroyama T, Kousaka H, Umehara N, Mabuchi Y, Higuchi T (2014) The effect of oil temperature and additive concentration on the wear of non-hydrogenated DLC coating. Tribol Int. https://doi.org/10.1016/j.triboint.2014.04.015

Erdemir A, Donnet C (2006) Tribology of diamond-like carbon films: recent progress and future prospects. J Phys D Appl Phys 39(18):311–327. https://doi.org/10.1088/0022-3727/39/18/r01

Dalibon EL, Trava-Airoldi V, Pereira LA, Cabo A, Brühl SP (2014) Wear resistance of nitrided and DLC coated PH stainless steel. Surf Coat Technol 255:22–27

Fedosenko G, Schwabedissen A, Engemann J, Braca E, Valentini L, Kenny JM (2002) Pulsed PECVD deposition of diamond-like carbon films. Diam Relat Mater 11:1047–1052

Lin CR, Wei DH, Chang CK, Liao WH (2011) Optical properties of diamond-like carbon films for antireflection coating by RF magnetron sputtering method. Phys Procedia 18:46–50

Lackner JM, Stottera C, Waldhauser W, Ebner R, Lenz W, Beutl M (2003) Pulsed laser deposition of diamond-like carbon coatings for industrial tribological applications. Surf Coat Technol 174:402–407

Lawes SDA, Fitzpatrick ME, Hainsworth SV (2007) Evaluation of the tribological properties of DLC for engine applications. J Phys D Appl Phys 40(18):5427–5437. https://doi.org/10.1088/0022-3727/40/18/s03

Vengudusamy B, Grafl A, Preinfalk K (2014) Tribological properties of hydrogenated amorphous carbon under dry and lubricated conditions. Diam Relat Mater 41:53–64. https://doi.org/10.1016/j.diamond.2013.11.009

Sniderman D (2016) Coatings and engineering are shaping tomorrow’s world, Tribology & Lubrication Technology 52–63

Cutiongco EC, Li D, Chung YW, Bhatia CS (1996) Tribological behavior of amorphous carbon nitride overcoats for magnetic thin-film rigid disks. J Tribol 118(3):543–548

Qian F, Craciun V, Singh R, Dutta S, Pronko P (1999) High intensity femtosecond laser deposition of diamond-like carbon thin films. J Appl Phys 86(4):2281–2290

Garrelie F, Loir A, Donnet C, Rogemond F, Le Harzic R, Belin M, Audouard E, Laporte P (2003) Femtosecond pulsed laser deposition of diamond-like carbon thin films for tribological applications. Surf Coat Technol 163:306–312

Grill A (1999) Diamond-like carbon: state of the art. Diam Relat Mater 8(2):428–434

Ronkainen H, Varjus S, Koskinen J, Holmberg K (2001) Differentiating the tribological performance of hydrogenated and hydrogen-free DLC coatings. Wear 249(3):260–266

Donnet C, Fontaine J, Grill A, Le Mogne T (2001) The role of hydrogen on the friction mechanism of diamond-like carbon films. Tribol Lett 9(3–4):137–142

Neuville S, Matthews A (2007) A perspective on the optimisation of hard carbon and related coatings for engineering applications. Thin Solid Films 515(17):6619–6653. https://doi.org/10.1016/j.tsf.2007.02.011

Von Fraunhofer J (2012) Adhesion and cohesion. Int J Dent. https://doi.org/10.1155/2012/951324

Morshed MM, Cameron DC, McNamara BP, Hashmi MSJ (2003) Pre-treatment of substrates for improved adhesion of diamond-like carbon films on surgically implantable metals deposited by saddle field neutral beam source. Surf Coatings Technol 579–583

Lin J, Sproul WD, Wei R, Chistyakov R (2014) Diamond like carbon films deposited by HiPIMS using oscillatory voltage pulses. Surf Coat Technol 258:1212–1222

Sharma N, Kumar N, Dash S, Das CR, Subba-Rao RV, Tyagi AK, Raj B (2012) Scratch resistance and tribological properties of DLC coatings under dry and lubrication conditions. Tribol Int 56:129–140

Claver A, Jiménez-Piqué E, Palacio JF, Almandoz E, De Ara JF, Fernández I, Santiago JA, Barba E, García JA (2021) Comparative study of tribomechanical properties of HiPIMS with positive pulses DLC coatings on different tools steels. Coatings 11(1):1–28. https://doi.org/10.3390/coatings11010028

Donnet C, Grill A, Fontaine J, Le Mogne F, Lefebvre C, Jannes, C (1998) Fundamental on the friction mechanism of diamond like carbon films. In: Proceedings of 25th Leeds-Lyon Symposium on Tribology, Lyon

Jokari-Sheshdeh M, Mahboubi F, Dehghani K (2018) Structure and tribological behavior of diamond-like carbon coatings deposited on the martensitic stainless steel: The influence of gas composition and temperature. Diam Relat Mater 81:77–88

Santiago JA, Fernández-Martínez I, Sánchez-López JC, Rojas TC, Wennberg A, Bellido-González V, Molina-Aldareguia JM, Monclús MA, González-Arrabal R (2019) Tribomechanical properties of hard Cr-doped DLC coatings deposited by low-frequency HiPIMS. Surf Coat Technol 382:124899. https://doi.org/10.1016/j.surfcoat.2019.124899

Morshed MM (2003) Adhesion and cohesion properties of diamond-like carbon coatings deposited on biomaterials by saddle field neutral fast atom beam source; measurement and modelling. PhD Thesis, Faculty of Engineering and Design, School of Mechanical and Manufacturing Engineering of Dublin City University, pp 41–42

Zhang S, Bui XL, Fu Y (2004) Magnetron-sputtered nc-TiC/a-C(Al) tough nano-composite coatings. Thin Solid Films 467:261–266

Siegal MP, Tallant DR, Provencio PN (2000) Ultra-hard carbon nano-composite films. Appl Phys Lett 76:3052

Qiang L, Zhang B, Zhou Y, Zhang JY (2013) Improving the internal stress and wear resistance of DLC film by low content Ti doping. Solid State Sci 20:17–22

Cui J, Qiang L, Zhang B, Ling X, Yang T, Zhang J (2012) Mechanical and tribological properties of Ti-DLC films with different Ti content by magnetron sputtering technique. Appl Surf Sci 258:5025–5030

Dearnley PA, Neville A, Turner S, Scheibe HJ, Tietema R, Tap R, Stuber M, Hovsepian P, Layyous A, Stenbom B (2010) Coatings tribology drivers for high density plasma technologies. Surf Eng 26(1–2):80–96

Michalewicz ZS (1954) Corrosion in the motor-car: 1. corrosive wear of piston rings and cylinders. Anti-Corros Methods Mater 1(6):194–199. https://doi.org/10.1108/eb018953

Mattox D (1987) Thin solid films. J Appl Phys 53:81–96

Mattox D (1963) J. McDonald. J Appl Phys 34:2493–2494

Marin E, Lanzutti A, Nakamura M, Zanocco M, Zhu W, Pezzotti G, Andreatta F (2019) Corrosion and scratch resistance of DLC coatings applied on chromium molybdenum steel. Surf Coat Technol 378:124944. https://doi.org/10.1016/j.surfcoat.2019.124944

Holmberg K, Matthews A (1994) Coatings tribology — properties, techniques and applications in surface engineering. Tribol Ser 442

Ronkainen H, Varjus S, Koskinen J (1992) Tribological properties of diamond-like carbon films. Tribological 11:133–141

Memming R, Tolle HJ, Wierenga PE (1986) Properties of polymeric layers of hydrogenated amorphous carbon produced by a plasma-activated chemical vapour deposition process, Tribological and mechanical properties. Thin Solid Films 143(1):31–41. https://doi.org/10.1016/0040-6090(86)90144-6

Robertson J (2002) Diamond-like amorphous carbon. Mater Sci Eng, R 37(4–6):129–281. https://doi.org/10.1016/s0927-796x(02)00005-0

Jansen F, Machonkin M, Kaplan S, Hark S (1985) The effects of hydrogenation on the properties of ion beam sputter deposited amorphous carbon. J Vac Sci Technol A: Vac Surf Films 3(3):605–609. https://doi.org/10.1116/1.572960

Savvides N (1984) Deposition parameters and film properties of hydrogenated amorphous silicon prepared by high rate dc planar magnetron reactive sputtering. J Appl Phys 55(12):4232–4238. https://doi.org/10.1063/1.333024

Lifshitz Y (1996) Hydrogen-free amorphous carbon films: correlation between growth conditions and properties. Diamond Relat Mater 5(3–5):388–400. https://doi.org/10.1016/0925-9635(95)00445-9

Aisenberg S, Chabot R (1971) Ion-beam deposition of thin films of diamond-like carbon. J Appl Phys 42(7):2953–2958. https://doi.org/10.1063/1.1660654

Collins CB, Davanloo F, Jander DR, Lee TJ, Park H, You JH (1991) Microstructure of amorphic diamond films. J Appl Phys 69(11):7862. https://doi.org/10.1063/1.347519

McKenzie DR, Muller D, Pailthorpe BA (1991) Compressive-stress-induced formation of thin-film tetrahedral amorphous carbon. Phys Rev Lett 67(6):773–776. https://doi.org/10.1103/PhysRevLett.67.773

Catherine Y (1991) Preparation techniques for diamond-like carbon. In: Clausing RE, Horton LL, Angus JC, Koidl P (eds) Diamond and diamond-like films and coatings. NATO ASI Series, vol 266. Springer, Boston. https://doi.org/10.1007/978-1-4684-5967-8_10

McKenzie DR (1996) Tetrahedral bonding in amorphous carbon. Rep Prog Phys 59(12):1611–1664. https://doi.org/10.1088/0034-4885/59/12/002

Bubenzer A, Dischler B, Brandt G, Koidl P (1983) RF-plasma deposited amorphous hydrogenated hard carbon thin films: preparation, properties, and applications”. J Appl Phys 54(8):4590–4595. https://doi.org/10.1063/1.332613

Wild C, Koidl P (1989) Structured ion energy distribution in radio frequency glow-discharge systems. Appl Phys Lett 54(6):505–507. https://doi.org/10.1063/1.100913

Moriguchi H, Ohara H, Tsujioka M (2016) History and applications of diamond-like carbon manufacturing processes. SEI Tech Rev 82:52–58

Koidl P, Wild CH, Dischler B, Wagner J, Ramsteiner M (1991) Plasma deposition, properties and structure of amorphous hydrogenated carbon films. Mater Sci Forum 52–53:41–70

Lieberman MA, Lichtenberg JA (2005) Principles of plasma discharges and materials processing: second edition 1–757 https://doi.org/10.1002/0471724254

Bonetti LF, Capote G, Santos LV, Corat EJ, Trava-Airoldi VJ (2006) Adhesion studies of diamond-like carbon films deposited on Ti6Al4V substrate with a silicon interlayer. Thin Solid Films 515(1):375–379. https://doi.org/10.1016/j.tsf.2005.12.154

Capote G, Bonetti LF, Trava-Airoldi VJ, Santos LV, Corat EJ (2008) Deposition of adherent DLC films using a low-cost enhanced pulsed- DC PECVD method. Revista Brasileira de Aplicações de Vácuo 25(4):209–213

Trava-Airoldi VJ, Bonetti LF, Capote G, Santos LV, Corat EJ (2007) A comparison of DLC film properties obtained by r.f. PACVD, IBAD, and enhanced pulsed-DC PACVD Surface and Coatings Technology 202 3 549–554 https://doi.org/10.1016/j.surfcoat.2007.06.030

Weiler M et al (1996) Preparation and properties of highly tetrahedral hydrogenated amorphous carbon. Phys Rev B Condens Matter Mater Phys 53(3):1594–1608. https://doi.org/10.1103/physrevb.53.1594

Weiler M, Lang K, Li E, Robertson J (1998) Deposition of tetrahedral hydrogenated amorphous carbon using a novel electron cyclotron wave resonance reactor. Appl Phys Lett 72(11):1314–1316. https://doi.org/10.1063/1.121069

Faraji G, Kim HS, Kashi HT (2018) Fundamentals of severe plastic deformation. Severe Plastic Deformation 19–36. https://doi.org/10.1016/B978-0-12-813518-1.00001-1

Baptista A, Silva F, Porteiro J, Míguez J, Pinto G (2018) Sputtering physical vapour deposition (PVD) coatings: A critical review on process improvement andmarket trend demands Coatings 8 11 https://doi.org/10.3390/Coatings8110402

Karabacak T, Jay J, Senkevich G, Wang C, Lu TM (2005) Stress reduction in sputter deposited films using nanostructured compliant layers by high working-gas pressures. J Vac Sci Technol A: Vac Surf Films 23(4):986–990. https://doi.org/10.1116/1.1861940

Helfrick AD, Cooper WD (1990) Modern electronic instrumentation and measurement techniques, Prentice Hall of India Private Limited, New Delhi

West AR (1987) Solid state chemistry and its applications. John Wiley Publications

Phillips VA (1972) Modern metallographic techniques and their applications. John Wiley & Sons Inc

Hall CE (1966) Introduction to electron microscopy. McGraw-Hill

Williams DB, Carter CB (2009) Transmission electron microscopy—a text book of materials science. Springer

Cullity BD (1956) Elements of X ray diffraction. In: Addison-Wesley M S (ed) Practical materials characterization, Springer Science+Business Media New York.

Ferrari AC, Robertson J (2000) Interpretation of Raman spectra of disordered and amorphous carbon. Phys Rev B 61(20):14095–14107. https://doi.org/10.1103/PhysRevB.61.14095

Briggs D, Wiley J (1983) Practical surface analysis by Auger and X-ray photoelectron spectroscopy. Pract Surf Anal by Auger X-ray Photoelectron Spectrosc 1:1–8. https://doi.org/10.1016/0368-2048(84)80044-4

Smith GC (1994) Surface analysis by electron spectroscopy. Plenum, New York, Estados Unidos, p 1994

Scofield J (1976) Hartree-Slater subshell photoionization cross-sections at 1254 and 1487 eV Journal of Electron Spectroscopy and Related Phenomena 8 2 129–137 https://doi.org/10.1016/0368-2048(76)80015-1

Bomben KD, Moulder JF, Stickle WF, Sobol PE (1992) Handbook of X-ray photoelectron spectroscopy, Perkin-Elmer Corporation Physical Electronics Division

Naumkin A, Kraut-Vass A, Gaarenstroom SW, Powell CJ (2014) NIST X-ray photoelectron spectroscopy database. NIST Standard Reference Database 20 20 https://doi.org/10.6028/NIST.NSRDS.164

ASTM (2015) ASTM C1624–05 standard test method for adhesion strength and mechanical failure modes of ceramic coatings by quantitative single point scratch testing https://doi.org/10.1520/C1624-05R15

ASTM (2009) ASTM G171 standard test method for scratch hardness of materials using a diamond stylus. ASTM Stand, 03

Bull SJ (1991) Failure modes in scratch adhesion testing. Surf Coat Technol 50(1):25–32. https://doi.org/10.1016/0257-8972(91)90188-3

Malkow T, Bull SJ (2001) Hardness measurements on thin IBAD CNx films — a comparative study. Surf Coat Technol 137(2–3):197–204. https://doi.org/10.1016/S0257-8972(00)01101-4

Burnett PJ, Rickerby DS (1987) The relationship between hardness and scratch adhesion. Thin Solid Films 154(1–2):403–416. https://doi.org/10.1016/0040-6090(87)90382-8

Hedenqvist P, Hogmark S (1997) Experiences from scratch testing of tribological PVD coatings. Tribol Int 30(7):507–516. https://doi.org/10.1016/s0301-679x(97)00014-5

Vidakis N, Antoniadis A, Bilalis N (2003) The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds. J Mater Process Technol 143–144(1):481–485. https://doi.org/10.1016/S0924-0136(03)00300-5

Zahid R, Masjuki HH, Varman M, Mufti RA, Kalam MA, Gulzar M (2015) Effect of lubricant formulations on the tribological performance of self-mated doped DLC contacts: a review. Tribol Lett 58(2):32. https://doi.org/10.1007/s11249-015-0506-5

Cavaleiro A, De Hosson J T M (2006) Nanostructured coatings. Nanostruct Sci Technol 1, 69

Isono R et al (1929) Improvement of adhesion of hydrogen-free DLC film by employing an interlayer of tungsten carbide. AIP Conf Proceed 1929(1):020019. https://doi.org/10.1063/1.5021932

Cemin F, Boeira CD, Figueroa CA (2016) On the understanding of the silicon-containing adhesion interlayer in DLC deposited on steel. Tribol Int 94:464–469. https://doi.org/10.1016/j.triboint.2015.09.044

Madej M (2014) The effect of TiN and CrN interlayers on the tribological behavior of DLC coatings. Wear 317(1–2):179–187. https://doi.org/10.1016/j.wear.2014.05.008

Wu G, Sun L, Dai W, Song L, Wang A (2009) Influence of interlayers on corrosion resistance of diamond-like carbon coating on magnesium alloy. Surf Coat Technol 204(14):2193–2196. https://doi.org/10.1016/j.surfcoat.2009.12.009

Kasiorowski T et al (2020) Microstructural and tribological characterization of DLC coatings deposited by plasma enhanced techniques on steel substrates. Surf Coatings Technol 389(March):125615. https://doi.org/10.1016/j.surfcoat.2020.125615

Bhowmick S, Banerji A, Lukitsch MJ, Alpas AT (2015) The high temperature tribological behavior of Si, O containing hydrogenated diamond-like carbon (a-C:H/a-Si:O) coating against an aluminum alloy. Wear 330–331:261–271. https://doi.org/10.1016/j.wear.2015.01.072

Banerji A, Bhowmick S (2014) Alpas AT (2014) High temperature tribological behavior of W containing diamond-like carbon (DLC) coating against titanium alloys. Surf Coat Technol 241:93–104. https://doi.org/10.1016/j.surfcoat.2013.10.075

Segura-Giraldo B, Restrepo-Parra E, Arango-Arango PJ (2009) On the influence of a TiN interlayer on DLC coatings produced by pulsed vacuum arc discharge: compositional and morphological study. Appl Surf Sci 256(1):136–141. https://doi.org/10.1016/j.apsusc.2009.07.094

Wang X et al (2021) Impacts of the a-Si: H interlayer nanostructure on the adhesion of the thick DLC coatings prepared by PECVD. Appl Surf Sci 565(July):150539. https://doi.org/10.1016/j.apsusc.2021.150539

Azzi M, Amirault P, Paquette M, Klemberg-Sapieha JE, Martinu L (2010) Corrosion performance and mechanical stability of 316L/DLC coating system: role of interlayers. Surf Coat Technol 204(24):3986–3994. https://doi.org/10.1016/j.surfcoat.2010.05.004

Bobzin K et al (2012) Behavior of DLC coated low-alloy steel under tribological and corrosive load: effect of top layer and interlayer variation. Surf Coat Technol 215:110–118. https://doi.org/10.1016/j.surfcoat.2012.08.075

Ilic E, Pardo A, Suter T, Mischler S, Schmutz P, Hauert R (2019) A methodology for characterizing the electrochemical stability of DLC coated interlayers and interfaces. Surf Coat Technol 375:402–413. https://doi.org/10.1016/j.surfcoat.2019.07.055

Shahsavari F, Ehteshamzadeh M, Amin MH, Barlow AJ (2019) A comparative study of surface morphology, mechanical and tribological properties of DLC films deposited on Cr and Ni nanolayers. Ceram Int 46(4):5077–5085. https://doi.org/10.1016/j.ceramint.2019.10.251

Patnaik L, Maity SR, Kumar S (2020) Comprehensive structural, nanomechanical and tribological evaluation of silver doped DLC thin film coating with chromium interlayer (Ag-DLC/Cr) for biomedical application. Ceram Int 46(14):22805–22818. https://doi.org/10.1016/j.ceramint.2020.06.048

Hincapie WSC, Gutiérrez JMB., Trava-Airoldi VJ, Olaya JJF, Alfonso JE, Capote G (2020) Influence of the TixSi and TixSi/a-Si:H interlayers on adherence of diamond-like carbon coatings. Diamond Relat Mater 109 https://doi.org/10.1016/j.diamond.2020.108079

Choudhury D, Lackner J, Fleming RA, Goss J, Chen J, Zou M (2017) Diamond-like carbon coatings with zirconium-containing interlayers for orthopedic implants. J Mech Behav Biomed Mater 68:51–61. https://doi.org/10.1016/j.jmbbm.2017.01.023

Takashima M, Ohtake N (2011) Influence of interlayer on wear and corrosion resistance of DLC film. J Solid Mech Mater Eng 5(12):938. https://doi.org/10.1299/jmmp.5.938

Liu L et al (2017) Excellent adhered thick diamond-like carbon coatings by optimizing hetero-interfaces with sequential highly energetic Cr and C ion treatment. J Alloy Compd 735:155–162. https://doi.org/10.1016/j.jallcom.2017.11.057

Weicheng K, Kangmei L, Jun H (2021) TEM structure, nanomechanical property, and adhesive force of magnetron-sputtered Cr-DLC coating on a nitrided Ti6Al4V Alloy. J Phys Chem C 125(30):16733–16745. https://doi.org/10.1021/acs.jpcc.1c03987

Pang X, Yang H, Gao K, Wang Y, Volinsky AA (2011) AlTiN layer effect on mechanical properties of Ti-doped diamond-like carbon composite coatings. Thin Solid Films 519(16):5353–5357. https://doi.org/10.1016/j.tsf.2011.02.040

Ward L, Junge F, Lampka A, Dobbertin M, Mewes C, Wienecke M (2014) The effect of bias voltage and gas pressure on the structure, adhesion and wear behavior of diamond-like carbon (DLC). Coatings Si interlayers Coatings 4(2):214–230. https://doi.org/10.3390/coatings4020214

Huang Z, Chen Z, Lang W, Wang W (2021) Adhesion studies of CrC/a-c:H coatings deposited with anode assisted reactive magnetron sputtering combined with DC-pulsed plasma enhanced chemical vapor deposition. Materials 14(11) https://doi.org/10.3390/ma14112954

Wang L, Li L, Kuang X (2018) Effect of substrate bias on microstructure and mechanical properties of WC-DLC coatings deposited by HiPIMS. Surf Coat Technol 352:33–41. https://doi.org/10.1016/j.surfcoat.2018.07.088

Evaristo M, Fernandes F, Cavaleiro A (2020) Room and high temperature tribological behaviour of W-DLC coatings produced by DCMS and hybrid DCMS-HiPIMS configuration. Coatings 10(4):319. https://doi.org/10.3390/coatings10040319

Lofaj F, Kabátová M, Klich M, Medve D, Girman V (2019) Tribological behavior of hydrogenated W-C/a-C: H coatings deposited by three different sputtering techniques. Ceramica 65:58–69. https://doi.org/10.1590/0366-6913201965S12577

Sun J et al (2013) Friction and wear of Cr-doped DLC films under different lubrication conditions. Vacuum 94:1–5. https://doi.org/10.1016/j.vacuum.2013.01.010

Ji L et al (2015) The role of trace Ti concentration on the evolution of microstructure and properties of duplex doped Ti(Ag)/DLC films. Vacuum 115:23–30. https://doi.org/10.1016/j.vacuum.2015.01.023

Amanov A, Watabe T, Tsuboi R, Sasaki S (2013) Fretting wear and fracture behaviors of Cr-doped and non-doped DLC films deposited on Ti-6al-4V alloy by unbalanced magnetron sputtering. Tribol Int 62:49–57. https://doi.org/10.1016/j.triboint.2013.01.020

Veverkova J, Hainsworth SV (2007) Effect of temperature and counterface on the tribological performance of W-DLC on a steel substrate. Wear 264(7–8):518–525. https://doi.org/10.1016/j.wear.2007.04.003

Ren Z, Qin H, Dong Y, Doll GL, Ye C (2019) A boron-doped diamond like carbon coating with high hardness and low friction coefficient. Wear 436–437(July):203031. https://doi.org/10.1016/j.wear.2019.203031

Bootkul D, Supsermpol B, Saenphinit N, Aramwit C, Intarasiri S (2014) Nitrogen doping for adhesion improvement of DLC film deposited on Si substrate by filtered cathodic vacuum arc (FCVA) technique. Appl Surf Sci 310:284–292. https://doi.org/10.1016/j.apsusc.2014.03.059

Guo T, Kong C, Li X, Guo P, Wang Z, Wang A (2017) Microstructure and mechanical properties of Ti/Al co-doped DLC films: Dependence on sputtering current, source gas, and substrate bias. Appl Surf Sci 410:51–59. https://doi.org/10.1016/j.apsusc.2017.02.254

Kalin M, Vižintin J (2006) Differences in the tribological mechanisms when using non-doped, metal-doped (Ti, WC), and non-metal-doped (Si) diamond-like carbon against steel under boundary lubrication, with and without oil additives. Thin Solid Films 515(4):2734–2747. https://doi.org/10.1016/j.tsf.2006.03.034

Kalin M, Roman E, Ožbolt L, Vižintin J (2010) Metal-doped (Ti, WC) diamond-like-carbon coatings: reactions with extreme-pressure oil additives under tribological and static conditions. Thin Solid Films 518(15):4336–4344. https://doi.org/10.1016/j.tsf.2010.02.066

Chou CC, Wu YY, Lee JW, Huang JC (2013) Yeh CH (2013) Mechanical properties of fluorinated DLC and Si interlayer on a Ti biomedical alloy. Thin Solid Films 528:136–142. https://doi.org/10.1016/j.tsf.2012.06.089

Müller IC, Sharp J, Rainforth WM, Hovsepian P, Ehiasarian A (2017) Tribological response and characterization of Mo–W doped DLC coating. Wear 376–377:1622–1629. https://doi.org/10.1016/j.wear.2016.11.036

Ren Z et al (2020) Tribological performance of 52,100 steel subjected to boron-doped DLC coating and ultrasonic nanocrystal surface modification. Wear 458–459:203398. https://doi.org/10.1016/j.wear.2020.203398

Bai M, Yang L, Li J, Luo L, Sun S, Inkson B (2021) Mechanical and tribological properties of Si and W doped diamond-like carbon (DLC) under dry reciprocating sliding conditions. Wear 484–485:204046. https://doi.org/10.1016/j.wear.2021.204046

Chang CL, Jao JY, Chang TC, Ho WY, Wang DY (2005) Influences of bias voltage on properties of TiAl-doped DLC coatings synthesized by cathodic arc evaporation. Diamond Relat Mater 14(11):2127–2132. https://doi.org/10.1016/j.diamond.2005.06.034

Pandey B, Pal PP, Bera S, Ray SK, Kar AK (2012) Effect of nickel incorporation on microstructural and optical properties of electrodeposited diamond like carbon (DLC) thin films. Appl Surf Sci 261:789–799. https://doi.org/10.1016/j.apsusc.2012.08.101

Kržan B, Novotny-Farkas F, Vižintin J (2009) Tribological behavior of tungsten-doped DLC coating under oil lubrication. Tribol Int 42(2):229–235. https://doi.org/10.1016/j.triboint.2008.06.011

Hovsepian PE, Mandal P, Ehiasarian AP, Sáfrán G, Tietema R, Doerwald D (2016) Friction and wear behaviour of Mo-W doped carbon-based coating during boundary lubricated sliding. Appl Surf Sci 366:260–274. https://doi.org/10.1016/j.apsusc.2016.01.007

Mutafov P, Lanigan J, Neville A, Cavaleiro PT (2014) DLC-W coatings tested in combustion engine — frictional and wear analysis. Surf Coat Technol 260:284–289. https://doi.org/10.1016/j.surfcoat.2014.06.072

Fu RKY, Mei YF, Fu MY, Liu XY (2005) Chu PK (2005) Thermal stability of metal-doped diamond-like carbon fabricated by dual plasma deposition. Diam Relat Mater 14(9):1489–1493. https://doi.org/10.1016/j.diamond.2005.03.006

Kolawole FO, Varela LB, Kolawole RMA, Tschiptschin AP (2020) Deposition and characterization of tungsten oxide (WO3) nanoparticles incorporated diamond-like carbon coatings using pulsed-DC PECVD. Mater Lett. https://doi.org/10.1016/j.matlet.2020.128645

Kolawole FO, Ramirez MA, Kolawole SK, Varela LB, Tschiptschin AP (2020) Deposition and characterization of molybdenum oxide (MoO3) nanoparticles incorporated diamond-like carbon coatings using pulsed-DC PECVD. Mater Lett 278 https://doi.org/10.1016/j.matlet.2020.128420

Tang XS, Wang HJ, Feng L, Shao ZCW (2014) Mo doped DLC nanocomposite coatings with improved mechanical and blood compatibility properties. Appl Surf Sci 311:758–762. https://doi.org/10.1016/j.apsusc.2014.05.155

Qiang L, Gao K, Zhang L, Wang J, Zhang B, Zhang J (2015) Further improving the mechanical and tribological properties of low content Ti-doped DLC film by W incorporating. Appl Surf Sci 353:522–529. https://doi.org/10.1016/j.apsusc.2015.06.040

Yue W, Wang S, Fu Z, Gao X, Yu X, Liu J (2012) Influence of W content on microstructural, mechanical and tribological properties of sulfurized W-doped diamond-like carbon coatings. Surf Coatings Technol 218(1):47–56. https://doi.org/10.1016/j.surfcoat.2012.12.026

Manninen NK, Ribeiro F, Escudeiro A, Polcar T, Carvalho S, Cavaleiro A (2013) Influence of Ag content on mechanical and tribological behavior of DLC coatings. Surf Coat Technol 232:440–446. https://doi.org/10.1016/j.surfcoat.2013.05.048

Lukaszkowicz K, Paradecka A, Wiśniewska J (2013) Structure and properties of CrN/DLC coating deposited by PVD ARC-cathodes and PACVD technology. Arch Mater Sci Eng 64(1):40–44

Mulligan CP, Senick M, Schmidt DP, Khominich V, Gay Z, Bell D (2014) CrN, CrN/SiC, and CrN/DLC coatings deposited by a novel arc plasma acceleration process: Processing and properties. Mater Manuf Process 29(9):1037–1043. https://doi.org/10.1080/10426914.2014.880470

Conde FF, Diaz JA ávila, Da Silva GF, Tschiptschin AP (2019) Dependence of wear and mechanical behavior of nitrocarburized/Crn/Dlc layer on film thickness. Mater Res 22(2):1–10. https://doi.org/10.1590/1980-5373-MR-2018-0499

Bujak J, Michalczewski R (2011) Characterization and properties of low-friction, multilayered Cr-doped diamond-like carbon coatings prepared by pulse biased filtered cathodic arc deposition. Proc Inst Mech Eng Part J: J Eng Tribol 225(8):875–882. https://doi.org/10.1177/1350650111411380

Solis J, Zhao H, Wang C, Verduzco JA, Bueno AS, Neville A (2016) Tribological performance of an H-DLC coating prepared by PECVD. Appl Surf Sci 383:222–232. https://doi.org/10.1016/j.apsusc.2016.04.184

Capote G, Mastrapa GC, Trava-Airoldi VJ (2015) Influence of acetylene precursor diluted with argon on the microstructure and the mechanical and tribological properties of a-C: H films deposited via the modified pulsed-DC PECVD method. Surf Coat Technol 284:145–152. https://doi.org/10.1016/j.surfcoat.2015.08.065

Takeno T, Sugawara T, Miki H, Takagi T (2009) Diamond & related materials deposition of DLC film with adhesive W-DLC layer on stainless steel and its tribological properties. Diam Relat Mater 18(5–8):1023–1027. https://doi.org/10.1016/j.diamond.2009.01.029

Gu K, Zheng Y, Luo J, Qin X, Yang X, Abbas N, Tang J (2019) Microstructure, mechanical and tribological properties of DLC/Cu-DLC/W-DLC composite films on SUS304 stainless steel substrates. Mater Res Express 6(8) https://doi.org/10.1088/2053-1591/ab197b.

Cao L, Liu J, Wan Y, Pu J (2020) Corrosion and tribocorrosion behavior of W doped DLC coating in artificial seawater. Diamond Relat Mater 109(April):108019. https://doi.org/10.1016/j.diamond.2020.108019

Shahsavari F, Ehteshamzadeh M, Naimi-Jamal MR, Irannejad A (2016) Nanoindentation and nanoscratch behaviors of DLC films growth on different thickness of Cr nanolayers. Diam Relat Mater 70:76–82. https://doi.org/10.1016/j.diamond.2016.10.003

Pu J, He D, Wang L (2015) Effects of WC phase contents on the microstructure, mechanical properties and tribological behaviors of WC/a-C superlattice coatings. Appl Surf Sci 357:2039–2047. https://doi.org/10.1016/j.apsusc.2015.09.181

Vijai BP, Yang Q, Kiran MSRN, Rha J, Nataraj D, Mangalaraj D (2012) Reactive biased target ion beam deposited W-DLC nanocomposite thin films - Microstructure and its mechanical properties. Diam Relat Mater 23:34–43. https://doi.org/10.1016/j.diamond.2011.12.016

Wang AY, Lee KR, Ahn JP, Han JH (2006) Structure and mechanical properties of W incorporated diamond-like carbon films prepared by a hybrid ion beam deposition technique. Carbon 44(9):1826–1832. https://doi.org/10.1016/j.carbon.2005.12.045

Sánchez-López JC, Fernández A (2008) Doping and alloying effects on DLC coatings. Tribology of diamond-like carbon films: fundamentals and applications, DLC 311–328 https://doi.org/10.1007/978-0-387-49891-1_12.

Yong Q, Ma G, Wang H, Chen S, Xu B (2016) Influence of tungsten content on microstructure and properties of tungsten-doped graphite-like carbon films. J Mater Res 31(23):3766–3776. https://doi.org/10.1557/jmr.2016.433

Miki H, Takeno T, Takagi T (2008) Tribological properties of multilayer DLC / W-DLC films on Si. Th Sol Fil 516(16):5414–5418. https://doi.org/10.1016/j.tsf.2007.07.113

Arslan A, Masjuki HH, Quazi MM, Kalam MA, Varman M, Jamshaid M, Rahman SMA, Imran M, Zulfattah ZM, Anwar MT, Gohar GA, Mandalan SM, Harith MH (2019) Experimental investigation of tribological properties of laser textured tungsten doped diamond like carbon coating under dry sliding conditions at various loads. Mater Res Express 6(10):106444. https://doi.org/10.1088/2053-1591/ab408c

Le Huu T, Zaidi H, Paulmier D, Voumard P (1996) Transformation of sp3 to sp2 sites of diamond like carbon coatings during friction in vacuum and under water vapour environment. Thin Solid Films 290–291(1996):126–130. https://doi.org/10.1016/S00406090(96)09198-5

Czyzniewski A, Gulbinski W, Radnóczi G, Szerencsi M, Pancielejko M (2011) Microstructure and mechanical properties of W-C: H coatings deposited by pulsed reactive magnetron sputtering. Surf Coat Technol 205(19):4471–4479. https://doi.org/10.1016/j.surfcoat.2011.03.062

Bhowmick S, Banerji A, Alpas AT (2015) Tribological behaviour of W-DLC against an aluminium alloy subjected to lubricated sliding. Tribol Ind 37(3):277–283

Konca E, Cheng YT, Weiner AM, Dasch JM, Alpas AT (2006) Elevated temperature tribological behavior of non-hydrogenated diamond-like carbon coatings against 319 aluminum alloy. Surf Coat Technol 200(12–13):3996–4005. https://doi.org/10.1016/j.surfcoat.2005.02.202

Mistry KK, Morina A, Erdemir A, Neville A (2013) Extreme pressure lubricant additives interacting on the surface of steel- and tungsten carbide-doped diamond-like carbon. Tribol Trans 56(4):623–629. https://doi.org/10.1080/10402004.2013.771415

Yang W et al (2014) Microstructure and properties of (Cr:N)-DLC films deposited by a hybrid beam technique. Surf Coat Technol 261:398–403. https://doi.org/10.1016/j.surfcoat.2014.10.044

Fu ZQ et al (2013) Influence of W content on tribological performance of W-doped diamond-like carbon coatings under dry friction and polyalpha olefin lubrication conditions. Mater Des 51:775–779. https://doi.org/10.1016/j.matdes.2013.04.098

Ye T, Ma J, Jia Z, Li T, Liu W, Yu W (2022) Microstructure, mechanical properties and low-temperature tribological behavior of Cr/Cr-W/W-DLC/DLC multilayer coatings on 5A06 Al alloy. J Mater Res Technol 18:810–819. https://doi.org/10.1016/j.jmrt.2022.03.002

M. Yan et al (2020) Friction and wear properties of GLC and DLC coatings under ionic liquid lubrication. Tribol Int 143 https://doi.org/10.1016/j.triboint.2019.106067

Reisel G, Irmer G, Wielage B (2006) Dorner-Reisel A (2006) Electrochemical corrosion behavior of carbon-based thin films in chloride ions containing electrolytes. Thin Solid Films 515(3):1038–1042. https://doi.org/10.1016/j.tsf.2006.07.063

Marin E et al (2019) Corrosion and scratch resistance of DLC coatings applied on chromium molybdenum steel. Surf Coatings Technol 378(July):124944. https://doi.org/10.1016/j.surfcoat.2019.124944

Zhu H et al (2017) Improvement in anti-corrosion property of hydrogenated diamond-like carbon film by modifying CrC interlayer. Diam Relat Mater 72:99–107. https://doi.org/10.1016/j.diamond.2017.01.013

Viswanathan S et al (2018) (2018) Corrosion and wear resistance properties of multilayered diamond-like carbon nanocomposite coating. Surf Interface Anal 50(3):265–276. https://doi.org/10.1002/sia.6353

Funding

The authors received financial support from the Petroleum Technology Development Funds (PTDF), Nigeria, and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) — Brazil process 141991/2019–4.

Author information

Authors and Affiliations

Contributions

Funsho Olaitan Kolawole — conceptualisation of the research work and writing, revision and editing of original draft. Olawale Samson Kolade — writing, revision and editing of original draft. Sefiu Adekunle Bello — writing, revision and editing of original draft. Shola Kolade Kolawole — writing, revision and editing of original draft. Aduramigba Toluwani Ayeni — writing of original draft and drawing diagrams. Temidayo Foluso Elijah — writing of original draft and drawing diagrams. André Paulo Tschiptschin — conceptualisation of the research work, supervision, revision and editing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Authors’ information

Not applicable.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kolawole, F.O., Kolade, O.S., Bello, S.A. et al. The improvement of diamond-like carbon coatings for tribological and tribo-corrosion applications in automobile engines: an updated review study. Int J Adv Manuf Technol 126, 2295–2322 (2023). https://doi.org/10.1007/s00170-023-11282-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11282-8