Abstract

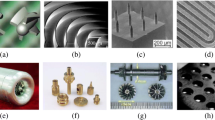

Structured abrasive tools (SATs) are considered as one of the next-generation abrasive tool solutions due to their superior ability to transport cutting fluids into grinding zones to lower grinding temperature and therefore enable high-quality machined surfaces. There are several SAT fabrication methods including mechanical, electroplating, brazing, and laser-based methods. Mechanical methods cannot produce SATs with small-sized structures due to significant contact forces, while electroplating has poor controllability of abrasive grain allocations. Brazing requires special machines with high-precision motion control, while laser-based methods need significant efforts on laser parameter selection and optimization. With this, here, we present a multiple-pass rotary wire electrical discharge machining (MPRWEDM) method to address the aforementioned limitations. We also develop a theoretical model of the created kerf profile during the MPRWEDM so as to enable controllable fabrication of SATs. The model was experimentally validated, showing a decent relative error of 9.8%. The nonlinear multiple-pass effect was studied both analytically and experimentally. Based on MPRWEDM, not only the SAT with designed grooves but also the structured surface (having an array of pyramid geometries) generated by the SAT were successfully created, proving the great potential of MPRWEDM in controllable production of even more advanced tools.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

Abbreviations

- a p :

-

Cut depth (m)

- d m :

-

Melting depth (m)

- h :

-

Equivalent workpiece thickness (m)

- I :

-

Peak discharge current (A)

- K :

-

Kerf width (m)

- k :

-

Gap distance between the kerf profile and any wire electrode point (m)

- L :

-

Distance between wire electrode points and workpiece rotation A-axis

- MRR :

-

Material removal rate (mm3*min−1)

- N :

-

Multiple pass number

- num :

-

The number of non-repeated discharge sparks

- p :

-

Wire feed distance in Y direction (m)

- R c :

-

Single pulse discharge center radius (m)

- R d :

-

Plasma channel radius (m)

- r :

-

Wire electrode radius (m)

- t num :

-

Duration time of num discharge sparks (s)

- t off :

-

The pulse interval (s)

- t on :

-

The pulse width (s)

- v m :

-

Wire moving speed (m*s−1)

- v s :

-

Relative wire cut speed (m*s−1)

- w :

-

Wire feed distance in Y direction (m)

- ∆B n :

-

Increment of kerf depth BBN (m)

- ∆C n :

-

Increment of kerf depth CCN (m)

- θ :

-

The angle of extension line OC0 and line OA (m)

- ω :

-

Workpiece rotation speed (rad*s−1)

References

Dai H, Zhang F, Chen J (2019) A study of ultraprecision mechanical polishing of single-crystal silicon with laser nano-structured diamond abrasive by molecular dynamics simulation. Int J Mech Sci 157–158:254–266

Li H, Zhao Y, Cao S, Chen H, Wu C, Qi H (2021) Controllable generation of 3D textured abrasive tools via multiple-pass laser ablation. J Mater Process Technol 295:117149

Zhang C, Guo B, Zhao Q, Liu H, Wang J, Zhang J (2019) Ultra-precision grinding of AlON ceramics: surface finish and mechanisms. J Eur Ceram Soc 39(13):3668–3676

Kumar V, Verma R, Kango S, Sharma VS (2021) Recent progresses and applications in laser-based surface texturing systems. Mater Today Commun 26:101736

Cui X, Li C, Zhang Y, Said Z, Debnath S, Sharma S, Muhammad Ali H, Yang M, Gao T, Li R (2022) Grindability of titanium alloy using cryogenic nanolubricant minimum quantity lubrication. J Manuf Process 80:273–286. https://doi.org/10.1016/j.jmapro.2022.06.003

Gao T, Li C, Yang M, Zhang Y, Jia D, Ding W, Debnath S, Yu T, Said Z, Wang J (2021) Mechanics analysis and predictive force models for the single-diamond grain grinding of carbon fiber reinforced polymers using CNT nano-lubricant. J Mater Process Technol 290:116976

Chen Z, Zhan S, Zhao Y (2021) Electrochemical jet-assisted precision grinding of single-crystal SiC using soft abrasive wheel. Int J Mech Sci 195:106239

Li H, Axinte D (2016) Textured grinding wheels: a review. Int J Mach Tools Manuf 109:8–35

Walter C, Komischke T, Weingärtner E, Wegener K (2014) Structuring of CBN grinding tools by ultrashort pulse laser ablation. Procedia CIRP 14:31–36

Xiao H, Yin S, Wang H, Liu Y, Wu H, Liang R, Cao H (2021) Models of grinding-induced surface and subsurface damages in fused silica considering strain rate and micro shape/geometry of abrasive. Ceram Int 47(17):24924–24941

Ding W, Zhao B, Zhang Q, Fu Y (2021) Fabrication and wear characteristics of open-porous cBN abrasive wheels in grinding of Ti–6Al–4V alloys. Wear 477:203786. https://doi.org/10.1016/j.wear.2021.203786

Qian H, Chen M, Qi Z, Teng Q, Qi H, Zhang L, Shan X (2023) Review on research and development of abrasive scratching of hard brittle materials and its underlying mechanisms. Crystals 13:428. https://doi.org/10.3390/cryst13030428

Azarhoushang B (2014) Wear of non-segmented and segmented diamond wheels in high-speed deep grinding of carbon fibre-reinforced ceramics. Int J Adv Manuf Technol 74(9–12):1293–1302

Xu W, Li C, Zhang Y, Muhammad Ali H, Sharma S, Li R, Yang M, Gao T, Liu M, Wang X, Said Z, Liu X, Zhou Z (2022) Electrostatic atomization minimum quantity lubrication machining: from mechanism to application. Int J Extrem Manuf 4:042003. https://doi.org/10.1088/2631-7990/ac9652

Sun Y, Su Z, Gong Y, Jin L, Wen Q, Qi Y (2020) An experimental and numerical study of micro-grinding force and performance of sapphire using novel structured micro abrasive tool. Int J Mech Sci 181:105741. https://doi.org/10.1016/j.ijmecsci.2020.105741

Guo B, Wu M, Zhao Q, Liu H, Zhang J (2018) Improvement of precision grinding performance of CVD diamond wheels by micro-structured surfaces. Ceram Int 44(14):17333–17339

Zhang X, Wen D, Shi Z, Li S, Kang Z, Jiang J, Zhang Z (2020) Grinding performance improvement of laser micro-structured silicon nitride ceramics by laser macro-structured diamond wheels. Ceram Int 46(1):795–802

Dabrowski L, Marciniak M (2001) Efficiency of special segmental grinding wheel. J Mater Process Technol 109(3):264–269

Cao Y, Ding W, Zhao B, Wen X, Li S, Wang J (2022) Effect of intermittent cutting behavior on the ultrasonic vibration-assisted grinding performance of Inconel718 nickel-based superalloy. Precis Eng 78:248–260

Cao Y, Yin J, Ding W, Xu J (2021) Alumina abrasive wheel wear in ultrasonic vibration-assisted creep-feed grinding of Inconel 718 nickel-based superalloy. J Mater Process Technol 297:117241

Cao Y, Zhu W, Ding W, Qiu Y, Wang L, Xu J (2022) Vibration coupling effects and machining behavior of ultrasonic vibration plate device for creep-feed grinding of Inconel 718 nickel-based superalloy. Chin J Aeronaut 35(2):332–345

Miao Q, Ding W, Xu J, Cao L, Wang H, Yin Z, Dai C, Kunag W (2021) Creep feed grinding induced gradient microstructures in the superficial layer of turbine blade root of single crystal nickel-based superalloy. Int J Extreme Manuf 3(4):045102

Mark JJ, Michael PH (2012) High performance grinding and advanced cutting tools. Springer, New York, NY

Mohamed A, Bauer R, Warkentin A (2014) A novel method for grooving and re-grooving aluminum oxide grinding wheels. Int J Adv Manuf Technol 73(5–8):715–725

Wang J, Li Y, Zhong M, Zhang H (2021) Investigation on a gas-atomized spray cooling upon flat and micro-structured surfaces. Int J Thermal Sci 161:106751

Silva E, Kirsch B, Bottene A, Simon A, Aurich J, Oliveira J (2017) Manufacturing of structured surfaces via grinding. J Mater Process Technol 243:170–183

Li L, Ren X, Jia W, Liu J, Zhu J (2010) Surface hydrophobic modification of ultra-fine aluminum silicate by mechanically grinding and heating. Appl Surf Sci 256(22):6824–6828

Denkena B, Köhler J, Wang B (2010) Manufacturing of functional riblet structures by profile grinding. CIRP J Manuf Sci Technol 3(1):14–26

Silva E, Oliveira J, Salles B, Cardoso R, Reis V (2013) Strategies for production of parts textured by grinding using patterned wheels. CIRP Ann 62(1):355–358

Aurich J, Kirsch B (2013) Improved coolant supply through slotted grinding wheel. CIRP Ann 62(1):363–366

Kim J, Kang Y, Jin D, Lee Y (1997) Development of discontinuous grinding wheel with multi-porous grooves. Int J Mach Tools Manuf 37(11):1611–1624

Dewar S, Bauer R, Warkentin A (2018) Application of high-angle helical-grooved vitrified wheels to cylindrical plunge grinding. Int J Adv Manuf Technol 96(5–8):2443–2453

Oliveira J, Bottene A, França T (2010) A novel dressing technique for texturing of ground surfaces. CIRP Ann Manuf Technol 59(1):361–364

Denkena B, Grove T, Göttsching T (2015) Grinding with patterned grinding wheels. CIRP J Manuf Sci Technol 8:12–21

Aurich J, Kirsch B, Herzenstiel P, Kugel P (2011) Hydraulic design of a grinding wheel with an internal cooling lubricant supply. Prod Eng Res Devel 5(2):119–126

Gavas M, Kina M, Köklü U (2015) Effects of various helically angled grinding wheels on the surface roughness and roundness in grinding cylindrical surfaces. Materiali in tehnologije 49(6):865–870

Mohamed A, Bauer R, Warkentin A (2013) Application of shallow circumferential grooved wheels to creep-feed grinding. J Mater Process Technol 213(5):700–706

Aurich J, Herzenstiel P, Sudermann H, Magg T (2008) High-performance dry grinding using a grinding wheel with a defined grain pattern. CIRP Ann 57(1):357–362

Yu H, Lyu Y, Wang J, Wang X (2018) A biomimetic engineered grinding wheel inspired by phyllotaxis theory. J Mater Process Technol 251:267–281

Lyu Y, Yu H, Wang J, Zhao G, Liu Z (2017) Improved performance of electroplated grinding wheels using a new method of controlled grain size sorting. J Manuf Process 30:336–342

Ding W, Xu J, Chen Z, Miao Q, Yang C (2013) Interface characteristics and fracture behavior of brazed polycrystalline CBN grains using Cu–Sn–Ti alloy. Mater Sci Eng A 559:629–634

Huang G, Huang J, Zhang M, Mu D, Zhou G, Xu X (2018) Fundamental aspects of ultrasonic assisted induction brazing of diamond onto 1045 steel. J Mater Process Technol 260:123–136

Deng H, Xu Z (2021) Laser dressing of arc-shaped resin-bonded diamond grinding wheels. J Mater Process Technol 288:116884

Li J, Wang W, Mei X, Pan A, Liu B, Cui J (2020) Rapid fabrication of microlens arrays on PMMA substrate using a microlens array by rear-side picosecond laser swelling. Opt Lasers Eng 126:105872

Rao X, Zhang F, Lu Y, Luo X, Ding F, Li C (2019) Analysis of diamond wheel wear and surface integrity in laser-assisted grinding of RB-SiC ceramics. Ceramics Int 45(18, Part A):24355–24364

Chen G, Mei L, Zhang B, Yu C, Shun K (2010) Experiment and numerical simulation study on laser truing and dressing of bronze-bonded diamond wheel. Opt Lasers Eng 48(3):295–304

Hosokawa A, Ueda T, Yunoki T (2006) Laser dressing of metal bonded diamond wheel. CIRP Ann 55(1):329–332

Xie X, Chen G, Li L (2004) Dressing of resin-bonded superabrasive grinding wheels by means of acousto-optic Q-switched pulsed Nd:YAG laser. Opt Laser Technol 36(5):409–419

Westkamper J (1994) Dressing of resin-bonded CBN grinding wheels by means of a pulsed Nd: YAG solid-state laser. Proc. Laser Assisted Net Shape Engineering, LANE'94 1:491

Khangar A, Dahotre N (2005) Morphological modification in laser-dressed alumina grinding wheel material for microscale grinding. J Mater Process Technol 170(1):1–10

Jackson MJ, Robinson G, Dahotre N, Khangar A, Moss R (2003) Laser dressing of vitrified aluminium oxide grinding wheels. Br Ceram Trans 102(6):237–245

Walter C, Komischke T, Kuster F, Wegener K (2014) Laser-structured grinding tools – generation of prototype patterns and performance evaluation. J Mater Process Technol 214(4):951–961

Chen G, Deng H, Zhou X, Zhou C, He J, Cai S (2015) Online tangential laser profiling of coarse-grained bronze-bonded diamond wheels. Int J Adv Manuf Technol 79(9):1477–1482

Chen G, Cai S, Zhou C (2015) On the laser-driven integrated dressing and truing of bronze-bonded grinding wheels. Diam Relat Mater 60:99–110

Guo B, Zhao Q, Fang X (2014) Precision grinding of optical glass with laser micro-structured coarse-grained diamond wheels. J Mater Process Technol 214(5):1045–1051

Li H, Xie K, Wu B, Zhu W (2020) Generation of textured diamond abrasive tools by continuous-wave CO2 laser: laser parameter effects and optimisation. J Mater Process Technol 275:116279

Chen Z, Yan Z, Zhou H, Han F, Zhao L, Yan H (2021) One-step fabrication of the wear-resistant superhydrophobic structure on SiCp/Al composite surface by WEDM. Surf Coat Technol 409:126876

Haddad M, Fadaei TA (2008) Material removal rate (MRR) study in the cylindrical wire electrical discharge turning (CWEDT) process. J Mater Process Technol 199(1):369–378

Wang X, Ying B, Liu W (1996) EDM dressing of fine grain super abrasive grinding wheel. J Mater Process Technol 62(4):299–302

Qu J, Shih A, Scattergood R (2002) Development of the cylindrical wire electrical discharge machining process, part 1: concept, design, and material removal rate. J Manuf Sci Eng 124(3):702–707

Tosun N, Cogun C, Tosun G (2004) A study on kerf and material removal rate in wire electrical discharge machining based on Taguchi method. J Mater Process Technol 152(3):316–322

Yadav V, Jain V, Dixit P (2002) Thermal stresses due to electrical discharge machining. Int J Mach Tools Manuf 42(8):877–888

Kansal H, Singh S, Kumar P (2008) Numerical simulation of powder mixed electric discharge machining (PMEDM) using finite element method. Math Comput Model 47(11):1217–1237

Mulimani P, Bhat R (2020) Investigating the effect of machining parameters on surface roughness in turning of nitrile rubber with conventional grinding wheel: application of Taguchi’s approach. Mater Today: Proc 28:2084–2089

Grützmacher PG, Profito FJ, Rosenkranz A (2019) Multi-scale surface texturing in tribology—current knowledge and future perspectives. Lubricants 7(11):95. https://doi.org/10.3390/lubricants7110095

Nishiyama H, Nishii J, Mizoshiri M, Hirata Y (2009) Microlens arrays of high-refractive-index glass fabricated by femtosecond laser lithography. Appl Surf Sci 255(24):9750–9753

Funding

This work was supported by the National Natural Science Foundation of China (51975302, 52175417), the Zhejiang Provincial Natural Science Foundation (LY20E050014, LQ22E050014, LQ20E050006), the Research Project of Key Laboratory of E&M (Zhejiang University of Technology) (EM202012014), the State Key Laboratory of Mechanical System and Vibration (MSV202120), and the Ningbo Municipal Natural Science Foundation (2019A610154, 202003N4184).

Author information

Authors and Affiliations

Contributions

All authors contributed to the material preparation, data collection, and experimental study. All authors commented on previous versions of the manuscript. The first draft of the manuscript was written by Bixuan Wang, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

This paper is the original research that has not been published previously nor is under consideration for publication elsewhere, in whole or in part.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflicts of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, B., Liu, G., Zhao, Y.J. et al. On the creation of structured abrasive tools via multiple-pass rotary wire EDM: A geometrical model. Int J Adv Manuf Technol 126, 3503–3522 (2023). https://doi.org/10.1007/s00170-023-11276-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11276-6