Abstract

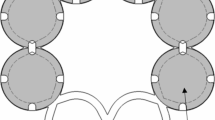

Traditionally manufactured for ropes and fishing lines, braids are now found in structural composite parts used in the transportation industries and the medical sector. Braiding machines are increasing in size and complexity. However, engineers mostly rely on expertise and on trials and errors to select a collision-free carrier arrangement, which is inefficient in terms of both time and resources. In this paper, we propose a method, based on graph theory, to detect collisions between carriers for any braiding machine configuration and for any number of carriers. To do so, the braiding machine is modeled as a graph. Each horngear is represented by a face and each horngear slot is represented by a vertex. A collision detection algorithm is developed, which validates or invalidates the proposed carrier arrangement. Two case studies are carried out to demonstrate the algorithm. The first one is carried out on a traditional maypole braiding machine, while the second one is done on a T-shape braider. The T-shape braider has a more complex configuration with horngears having different number of slots and diameters. The developed solution is an efficient method to detect collisions based on any carrier arrangement.

Similar content being viewed by others

References

Giurgiutiu V (2016) Structural Health Monitoring of Aerospace Composites. Elsevier. https://doi.org/10.1016/C2012-0-07213-4

Slayton R, Spinardi G (2016) Radical innovation in scaling up: Boeing’s Dreamliner and the challenge of socio-technical transitions. Technovation 47:47–58

Mallick PK (2007) Fiber-reinforced composites: materials, manufacturing, and design. CRC Press. https://doi.org/10.1201/9781420005981

Okano M, Nakai A, Hamada H (2005) Axial crushing performance of braided composite tubes. Int J Crashworthiness 10:287–294

Hamada H (1997) Can braided composites be used for crushing elements in cars. Proc. ICCM-11, 1, 218-46

Ko FK, Pastore CM, Head AA (1989) Atkins & Pearce handbook of industrial braiding. Atkins & Pearce, Covington

Potluri P, Rawal A, Rivaldi M, Porat I (2003) Geometrical modelling and control of a triaxial braiding machine for producing 3D preforms. Compos A: Appl Sci Manuf 34:481–492

Harris B (2003) Fatigue in composites: science and technology of the fatigue response of fibre-reinforced plastics. Woodhead Publishing, Sawston

Bilisik K (2013) Three-dimensional braiding for composites: a review. Text Res J 83:1414–1436

Wang Z, Zhang G, Zhu Y, Zhang L, Shi X, Wang W (2019) Theoretical analysis of braiding strand trajectories and simulation of three-dimensional parametric geometrical models for multilayer interlock three-dimensional tubular braided preforms. Text Res J 89(19-20):1306–4322

Yu Q, Sun Z, Qiu Y, Zhou S, Chen Y, Wu J et al (2017) Study on the braiding of preform with special-shaped sections based on the two-dimensional braiding process. Text Res J 89:172–181

de Oliveira Simões J, Marques AT (2001) Determination of stiffness properties of braided composites for the design of a hip prosthesis. Compos A: Appl Sci Manuf 32: 655–662

Mehboob H, Chang S-H (2014) Application of composites to orthopedic prostheses for effective bone healing: A review. Compos Struct 118:328–341

Huang Z ming (2000) The mechanical properties of composites reinforced with woven and braided fabrics. Compos Sci Technol 60(4):479-498

Tada M, Uozumi T, Nakai A, Hamada H (2001) Structure and machine braiding procedure of coupled square braids with various cross sections. Compos A: Appl Sci Manuf 32:1485–1489

Kyosev Y (2014) Machine configurator for braided composite profiles with arbitrary cross section. In: 16th European conference on composite materials ECCM. Vol. 16, 22-26.06.2014. Seville-Spain

Chengjie D, Zhuo M, Yujing Z, Yize S (2019) Modeling and analysis of the carrier arrangement in square rotary braiding. Text Res J 89:4208–4219

Agnarsson G, Greenlaw R (2006) Graph theory: Modeling, applications, and algorithms. Pearson-Prentice Hall, Hoboken

Farrahi AH, Goldberg AT, Bagasol L, Jung J (2017) Applying graph theory to problems in air traffic management. In: 17th AIAA Aviation Technology, Integration, and Operations Conference, p 3775. https://doi.org/10.2514/6.2017-3775

Likaj R, Shala A, Mehmetaj M, Hyseni P, Bajrami X (2013) Application of graph theory to find optimal paths for the transportation problem. IFAC Proc Vol 46:235–240

Farid G, Cocuzza S, Younas T, Razzaqi AA, Wattoo WA, Cannella F et al (2022) Modified A-Star (A*) Approach to Plan the Motion of a Quadrotor UAV in Three-Dimensional Obstacle-Cluttered Environment. Appl Sci 12:5791

Ding Z, Li J, Yang M, Yan Z, Li B, Chen W (2020) A Multi-channel Anti-collision Algorithm in Multi-reader RFID Networks. In: International Conference on Smart Grid and Internet of Things, pp 220–238. https://doi.org/10.1007/978-3-030-69514-9_18

Bondy JA, Murty USR (1976) Graph theory with applications vol. 290. Macmillan, London

Funding

This work was supported by The Natural Sciences and Engineering Research Council of Canada [NSERC, RDCPJ 543847–19]; PRIMA Quebec [R18-13–003]; FilSpec Inc; Pultrusion Techniques; and Bauer Hockey ltd.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Assi, P., Achiche, S. & Laberge Lebel, L. Application of graph theory for detecting carriers’ collisions in braiding machines. Int J Adv Manuf Technol 126, 2337–2348 (2023). https://doi.org/10.1007/s00170-023-11245-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11245-z