Abstract

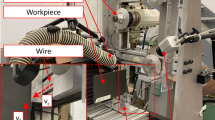

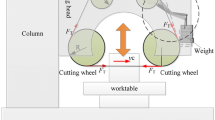

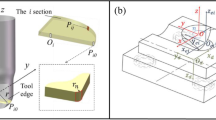

Diamond wire sawing (DWS) is often used to cut and slice crystalline silicon. The machining accuracy of DWS is a key performance of wire sawing. However, due to the inconsistent deformation of diamond wire relative to the workpiece in different sawing directions, the machining accuracy is different. In this paper, the machining accuracy of DWS in rip sawing and cross sawing was compared. Sawing tests were designed for rip sawing and cross sawing in different feed directions. The length of sawing kerf was used for the evaluation of machining accuracy. It was found that the machining accuracy of diamond wire pushing the workpiece (rip +) is obviously better than that of pulling the workpiece (rip −) in rip sawing as the wire stiffness of rip + is higher. The machining accuracy of cross sawing in different feed directions is related not only to wire stiffness, but also related to the wire torsion produced by lateral feed force in cross sawing. Therefore, the order of machining accuracy 1X + > 4Y − > 2Y + > 3X − shows that the cross sawing accuracy does not show an obvious law relative to rip sawing. A diamond wire electrical discharge sawing (DWEDS) was proposed in rip sawing and cross sawing to compare the machining accuracy of DWS. It was found that the machining accuracy of DWEDS is higher than that of DWS. No significant differences were found in machining accuracy between rip sawing and cross sawing in DWEDS. Finally, the characteristics of cutting force in time–frequency domain were analyzed.

Similar content being viewed by others

Data availability

All allowed data has been provided in the manuscript.

References

Hardin CW, Qu J, Shih AJ (2004) Fixed abrasive diamond wire saw slicing of single-crystal silicon carbide wafers. Mater Manuf Process 19(2):355–367

Clark WI, Shih AJ, Hardin CW (2003) Fixed abrasive diamond wire machining-part I: process monitoring and wire tension force. Int J Mach Tool Manu 43(5):523–532

Chakraborty S, Mitra S, Bose D (2021) Experimental investigation on enhancing die corner accuracy during powder mixed wire EDM of Ti6Al4V. Materials Today: Proceedings 38:3097–3102

Li ZQ, Ge PQ, Bi WB, Li CY (2021) Influence of silicon anisotropy on surface shape deviation of wafer by diamond wire saw. Mat Sci Semicon Proc 133:105981

Lin Z, Huang H, Xu X (2019) Experimental and simulational investigation of wire bow deflection in single wire saw. The Int J Adv Manuf Tech 101:687–695

Ebisu T, Kawata A, Okamoto Y, Okada A, Kurihara H (2018) Influence of jet flushing on corner shape accuracy in wire EDM. Procedia CIRP 68:104–108

Sarkar S, Sekh M, Mitra S (2011) A novel method of determination of wire lag for enhanced profile accuracy in WEDM. Precis Eng 35(2):339–347

Sanchez JA, Rodil JL, Herrero A (2007) On the influence of cutting speed limitation on the accuracy of wire-EDM corner-cutting. J Mater Process Technol 182(1–3):574–579

Wang J, Jia Z, Guo YB (2018) Shape-cutting of quartz glass by spark discharge-assisted diamond wire sawing. J Manuf Process 34:131–139

Kimura A, Okamoto Y, Okada A (2013) Fundamental study on multi-wire EDM slicing of SiC by wire electrode with track-shaped section. Procedia Cirp 6:232–237

Chen Z, Zhang G, Yan H (2018) A high-precision constant wire tension control system for improving workpiece surface quality and geometric accuracy in WEDM. Precis Eng 54:51–59

Nakagawa T, Sampei M, Hirata A (2020) High accuracy control with lateral dimension estimator for wire EDM. Procedia CIRP 95(52):255–261

Wang J, Fu C, Jia Z (2017) Cutting of hard and brittle insulating materials using spark discharge-assisted diamond wire sawing. J Mater Process Technol 252:225–232

Funding

This work was supported by Key Research and Development Program of Shandong Province, China (No. 2022CXGC010201), by allowing the facilities to conduct this work.

Author information

Authors and Affiliations

Contributions

Jian Qiu: conceptualization, methodology, data curation, software, writing — original draft, visualization, validation, program. Jianzhuang Lv: validation.

Corresponding author

Ethics declarations

Ethical approval

This work has no research involving human participants and/or animals.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qiu, J., Lv, J. Machining accuracy and force characteristic of diamond wire sawing and diamond wire electrical discharge sawing during rip sawing and cross sawing. Int J Adv Manuf Technol 126, 697–707 (2023). https://doi.org/10.1007/s00170-023-11132-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11132-7