Abstract

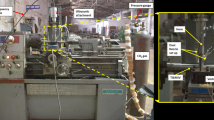

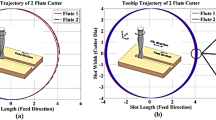

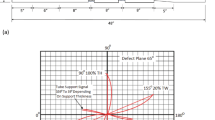

The use of tube hydroforming process to produce integrated parts is growing in various industries. In this research, the hydroforming process has been used to convert the circular cross-section of the tube into a square one. In this process, due to the high hydrostatic pressure of the fluid, the friction in the contact area between the tube and the die surface increases significantly. High friction prevents the metal flowing of the tube material on the die surface, and therefore it becomes very difficult to completely form the tube inside the die and obtain sharp corners. In this research, in order to improve the tube formability, applying ultrasonic vibrations to the hydroforming die has been used, which causes a temporary gap to be created in the contact surface of the tube and the die, and therefore the amount of friction is reduced and the tube material can slide more easily. By developing a 3D finite element model, the ultrasonic tube hydroforming process was evaluated. Modal analysis was used to evaluate the different shape modes of the die. The effects of ultrasonic vibrations on the deformation process have been evaluated using two variables: corner radius of square die and average wall thickness. An ultrasonic hydroforming setup was designed to form the annealed copper tube and was stimulated using selected resonance frequencies. The results of the finite element model were validated with the deformed tube in the experimental test. After confirming the results, the numerical model was used to evaluate the process parameters.

Similar content being viewed by others

References

Saboori M et al (2014) Evaluating the flow stress of aerospace alloys for tube hydroforming process by free expansion testing. Int J Adv Manuf Technol 72(9):1275–1286

Ma J et al (2021) Residual contact pressure and elastic recovery of an assembled camshaft using tube hydroforming. CIRP J Manuf Sci Technol 32:287–298

Ahmetoglu M et al (2000) Tube hydroforming: current research, applications and need for training. J Mater Process Technol 98(2):224–231

Lang L et al (2004) Hydroforming highlights: sheet hydroforming and tube hydroforming. J Mater Process Technol 151(1–3):165–177

Zhu H et al (2020) The development of a novel forming limit diagram under nonlinear loading paths in tube hydroforming. Int J Mech Sci 172:105392

Chan LC, Kot WKR (2014) Determination of loading paths in warm hydroforming reinforced quadrilateral tubular components. Mater Manuf Processes 29(1):32–36

Khalfallah A et al (2020) Constitutive parameter identification of CB2001 yield function and its experimental verification using tube hydroforming tests. Int J Mech Sci 185:105868

Ahmadi Brooghani S et al (2014) Loading path optimization of a hydroformed part using multilevel response surface method. Int J Adv Manuf Technol 70(5):1523–1531

Hwang Y-M, Chen W-C (2005) Analysis of tube hydroforming in a square cross-sectional die. Int J Plast 21(9):1815–1833

Hashemi SJ, Rahmani F (2018) Investigation of the geometry of rectangular cross section aluminum parts in low pressure tube hydroforming process. Trans Indian Inst Met 71(6):1445–1453

Nikhare C, Weiss M, Hodgson P (2009) FEA comparison of high and low pressure tube hydroforming of TRIP steel. Comput Mater Sci 47(1):146–152

Mori K, Maeno T, Maki S (2007) Mechanism of improvement of formability in pulsating hydroforming of tubes. Int J Mach Tools Manuf 47(6):978–984

Loh-Mousavi M et al (2007) 3-D finite element simulation of pulsating T-shape hydroforming of tubes. In Key Engineering Materials. Trans Tech Publ 340:353–358

Loh-Mousavi M et al (2010) Mechanism of filling of die corners in pulsating hydroforming of tube with box die. Modares Mech Eng 37:121–133

Ma J et al (2021) Evaluating the quality of assembled camshafts under pulsating hydroforming. J Manuf Process 61:69–82

Ning F, Cong W (2020) Ultrasonic vibration-assisted (UV-A) manufacturing processes: state of the art and future perspectives. J Manuf Process 51:174–190

Malekipour E et al (2020) Effect of resonant frequency variation on the ultrasonically assisted deep drawing process: numerical and experimental study. Int J Adv Manuf Technol 106(5):2243–2264

Wu L et al (2021) Effect of ultrasonic and low frequency vibrations on friction coefficient at die radius in deep drawing process. J Manuf Process 71:56–69

Malekipour E et al (2022) Observation on the behavior of ultrasonic micro-hammer and its effects on the deep drawing process: numerical simulation and experimental study. Ultrasonics 119:106566

Liu S et al (2020) Finite element analysis on ultrasonic drawing process of fine titanium wire. Metals 10(5):575

Liu S et al (2022) Stress superposition effect in ultrasonic drawing of titanium wires: an experimental study. Ultrasonics 106775

Kang J, Liu X, Xu M (2020) Plastic deformation of pure copper in ultrasonic assisted micro-tensile test. Mater Sci Eng A 785:139364

Cao M et al (2020) Mechanism of ultrasonic vibration assisted upsetting of 6061 aluminum alloy. J Manuf Process 59:690–697

Wang X, Qi Z, Chen W (2021) Investigation of mechanical and microstructural characteristics of Ti–45Nb undergoing transversal ultrasonic vibration-assisted upsetting. Mater Sci Eng A 813:141169

Zhai J et al (2022) The surface effect of ultrasonic vibration in double cup extrusion test. J Mater Process Technol 299:117344

Xu L et al (2019) Research on the micro-extrusion process of copper T2 with different ultrasonic vibration modes. Metals 9(11):1209

Han G et al (2021) Experimental investigation into effects of different ultrasonic vibration modes in micro-extrusion process. J Manuf Process 67:427–437

Su CJ et al (2018) Plastic deformation of magnesium alloy with different forming parameters during ultrasonic vibration-assisted single-point incremental forming. Rare Metals 1–9

Sedaghat H, Xu W, Zhang L (2019) Ultrasonic vibration-assisted metal forming: constitutive modelling of acoustoplasticity and applications. J Mater Process Technol 265:122–129

Mousavi SA, Feizi H, Madoliat R (2007) Investigations on the effects of ultrasonic vibrations in the extrusion process. J Mater Process Technol 187:657–661

Hung J-C, Tsai Y-C, Hung C (2007) Frictional effect of ultrasonic-vibration on upsetting. Ultrasonics 46(3):277–284

Bunget C, Ngaile G (2011) Influence of ultrasonic vibration on micro-extrusion. Ultrasonics 51(5):606–616

Yao Z et al (2012) Effects of superimposed high-frequency vibration on deformation of aluminum in micro/meso-scale upsetting. J Mater Process Technol 212(3):640–646

Siddiq A, El Sayed T (2011) Acoustic softening in metals during ultrasonic assisted deformation via CP-FEM. Mater Lett 65(2):356–359

Siddiq A, El Sayed T (2012) Ultrasonic-assisted manufacturing processes: variational model and numerical simulations. Ultrasonics 52(4):521–529

Blaha F, Langenecker B (1955) Tensile deformation of zinc crystal under ultrasonic vibration. Naturwissenschaften 42(556):1–10

Langenecker B (1961) Work-softening of metal crystals by alternating the rate of glide strain. Acta Metall 9(10):937–940

Langenecker B (1966) Effects of ultrasound on deformation characteristics of metals. IEEE Trans Sonics Ultrason 13(1):1–8

Eftekhari SE et al (2014) Improve the formability in tube hydroforming process using ultrasonic vibrations. Modares Mechanical Engineering 14(5):63–72

Rose JL (2014) Ultrasonic guided waves in solid media. Cambridge University Press

Rasoli M et al (2012) Influence of ultrasonic vibrations on tube spinning process. J Mater Process Technol 212(6):1443–1452

Cheers CF (1995) Design and optimisation of an ultrasonic die system for forming metal cans. Loughborough University

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by Seyyed Ehsan Eftekhari Shahri. Numerical simulation, formal analysis, and validation were performed by Mohammad Lakhi and Iman Taheri Doostabad. The first draft of the manuscript was written by Seyyed Ehsan Eftekhari Shahri, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Eftekhari Shahri, S.E., Lakhi, M. & Taheridoustabad, I. Numerical and experimental investigation of the ultrasonic vibration effects on the tube hydroforming process in a die with a square cross-section. Int J Adv Manuf Technol 126, 197–207 (2023). https://doi.org/10.1007/s00170-023-11081-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11081-1