Abstract

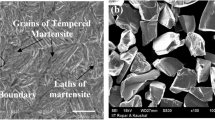

Mathematical techniques such as Support Vector Regression (SVR) and Multi-Objective Genetic Algorithms (MOGA) were used for a multi-objective optimization of corrosion rate (Rcorr) and hardness in an API 5L X70 steel welded by submerged arc welding (SAW) process with a double-V bevel shape. The inner and outer bevels (IB and OB, respectively) were joined at different conditions of voltage (V ), amperage (A) and travel speed in inches per minute (TS (ipm)), with a range in heat input (Q) of 1278–1693 J/mm. As Q is responsible for the microstructural behavior of the welds, their particular characteristics are defined by welding parameters giving as response variables the hardness and Rcorr in the fusion zone (FZ). For the experimental corrosion evaluation, the samples were tested in the FZ and base metal (BM) with potentiodynamic polarization test by three-electrode cell in an H2O + 3.5 wt.% NaCl electrolyte, and the Vickers microhardness (HV ) profiles were measured with a 500 g force. The experimental results (HV and Rcorr) were used for the corresponding prediction and optimization by SVR and MOGA. The main results show that Rcorr using optimized parameters decreases significantly from 2.356 mils per year (mpy) to 0.577 mpy in the FZ with a predominant microstructure of acicular ferrite (AF) and small regions of ferrite at the grain boundary (FGB). For the hardness, the predicted results were 217.36 HV (IB) and 225.63 HV (OB) against the 224.58 HV and 215.75 HV recorded in the validation sample revealing the great effectiveness of the applied method for prediction and optimization.

Similar content being viewed by others

References

Clover D, Kinsella B, Pejcic B, de Marco R (2005) The influence of microstructure on the corrosion rate of various carbon steels. J Appl Electrochem 35:139–149

Tamura H (2008) The role of rusts in corrosion and corrosion protection of iron and steel. Corros Sci 50:1872–1883

Katiyar PK, Misra S, Mondal K (2018) Effect of different cooling rates on the corrosion behavior of high-carbon pearlitic steel. J Mater Eng Perform 27:1753–1762

Cervantes-Tobón A, Díaz-Cruz M, Gónzalez-Velázquez JL, Godínez-Salcedo JG (2014) Effect of corrosion products formed and flow rate over the surface of steels API 5L X-52 and X-70 on the rate of corrosion in brine added with kerosene and H2S. Int J Electrochem Sci 9:2254–2265

Jacobo LR, García-Hernández R, López-Morelos VH, Contreras A (2021) Effect of acicular ferrite and bainite in API X70 steel obtained after applying a heat treatment on corrosion and cracking behaviour. Met Mater Int 27:3750–3746

Alizadeh M, Bordbar S (2013) The influence of microstructure on the protective properties of the corrosion product layer generated on the welded api x70 steel in chloride solution. Corros Sci 70:170–179

Selco JI, Jr. JLR, Wacks DB (2003) The analysis of seawater: a laboratory-centered learning project in general chemistry. J Chem Educ 80:54–57

Al-Fozan SA, Malik AU (2008) Effect of seawater level on corrosion behavior of different alloys. Desalination 228:61–67

Qaban A, Naher S (2019) Investigation of corrosion resistance of high-strength low-alloy (HSLA) steel in fresh and salt water for pipeline application, vol 2146

Larrabee CP (1958) Corrosion-resistant experimental steels for marine applications. CORROSION The Journal of Science & Engineering 14:21–24

Wen YF, Cai CZ, Liu XH-, Pei JF, Zhu XJ, Xiao TT (2009) Corrosion rate prediction of 3C steel under different seawater environment by using support vector regression. Corros Sci 51:349–355

Dearden J, OŃeill H (1940) A guide to the selection and welding of low alloy structural steels. Transactions of the Institute of Welding 3:203–214

Ito Y, Bessyo K (1968) Weldability formula of high strength steels related to heat affected zone cracking. International Institute of Welding IX:576–68

Al-rubaiey IS, Anoon EA, Hanoon MM (2013) The influence of microstructure on the corrosion rate of carbon steels. Engineering and Technology Journal 31:1825–1836

Omweg GM, Frankel GS, Bruce WA, Ramírez JE, Koch G (2003) Underwater welding-recent trends and future scope. Weld J 82:136–144

Balasubramanian M, Jayabalan V, Balasubramanian V (2008) Optimizing pulsed current parameters to minimize corrosion rate in gas tungsten arc welded titanium alloy. International Journal of Advance Manucaturing Technology 39:474–481

Rajakumar S, Balasubramanian V (2012) Optimizing pulsed current parameters to minimize corrosion rate in gas tungsten arc welded titanium alloy. J Mater Eng Perform 21:809– 822

Rambabu G, Naik DB, Rao CHV, Rao KS, Reddy GM (2015) Optimization of friction stir Welding parameters for improved corrosion resistance of AA2219 aluminium alloy joints. Defence Technology 11:330–337

Zhang C, Huang G, Cao Y, Wu X, Liu Q (2019) Optimization of tensile and corrosion properties of dissimilar friction stir welded AA2024-7075 joints. J Mater Eng Perform 28:183–199

Hariharan SJ, Vigneshwar M, Selvamani ST, Shanmugam K, Palanikumar K (2019) Optimizing the plasma arc welding process parameters to attain the minimum corrosion rate in the AISI 409M grade ferritic stainless steel autogenous joints. Materials Today: Proceedings 16:1259–1270

Arunmani A, Senthilkumar T (2020) Enhacing corrosion resistance of A-TIG welded UNS S32750 joint by optimizing its technological parameters. Chemical Industry & Chemical Engineering Quarterly 26:249–257

Lv Y, Wang J, Wang J, Xiong C, Zou L, Li L (2020) Steel corrosion prediction based on support vector machines. Chaos Solitons Fractals 109807:136

Srinivasan L, Chand-Khan M, Bharati T, Sathiya P, Biju S (2018) Appliction of genetic algorithm optimization technique in TIG Welding of 15CDV6 aerospace steel. Silicon 11:459– 469

Xinyu C, Yingbo Z, Jiaheng L, Hui C (2020) Composition design of 7XXX aluminium alloys optimizing stress corrosion cracking resistance using machine learning. Materials Research Express 046506:7

Costa P, Reyes-Valdéz F, na-Garcés RS, González-González D (2015) Optimización de los parámetros de soldadura por arco sumergido en acero hsla: una aplicación para manufactura de tuberías de conducción de hidrocarburos. Soldagem & Inspeção 20:456–466

Society AW (2017) AWS D3.6: Underwater Welding code, pp 148. American Welding Society

Vapnik VN (1999) The Nature of Statistical Learning Theory. Springer, Chap. 6

Deb K, Pratap A, Agarwal S, Meyarivan T (2002) A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Comput 6:182–197

Jorge JCF, de Souza LFG, Mendes MC, Bott IS, Araujo LS, dos Santos VR, Rebello JMA, Evans GM (2021) Microstructure characterization and its relationship with impact toughness of c-mn and high strength low alloy steel weld metals-a review. J Market Res 10:471–501

Abson DJ (2018) Acicular ferrite and bainite in c–mn and low-alloy steel arc weld metals. Sci Technol Weld Join 23:635–648

Loder D, Michelic S, Bernhard C (2017) Acicular ferrite formation and its influencing factors - a review. Journal of Materials Science Research 6:24–43

Choi CL, Hill DC (1978) A study of microstructural progression in as-deposited weld metal. Weld J 57:232–6

Sherif E-SM, Almajid AA (2015) Electrochemical corrosion behavior of API X-70 5L grade steel in 4.0 wt. time. Int J Electrochem Sci 10:34–35

Acknowledgements

The author Luis A. Guía-Hernández is indebted to CONACYT for the provided scholarship to pursue a doctoral degree. Also, the authors would like to thank COMIMSA for the provided equipment facilities.

Funding

This research has been funded by the Tecnológico Nacional de México through the research project 14487.22-P.

Author information

Authors and Affiliations

Contributions

Guía-Hernández, L.A.: experimental methodology, experimental validation, analysis, investigation, writing—original draft, writing review and editing, visualization. Ochoa-Palacios R.M.: experimental methodology, experimental validation, analysis, investigation, writing—original draft, writing review and editing. Reséndiz-Flores, E.O.: conceptualization, mathematical methodology, numerical implementation, numerical analysis, investigation, computational resources, writing—original draft, writing review and editing, supervision, project administration. Costa, P.S.: experimental methodology and resources, investigation, project administration. Reséndiz-Hernández, P.J.: experimental results interpretation. Altamirano-Guerrero, G.: experimental results interpretation.

Corresponding author

Ethics declarations

Ethics approval

The authors declare that this manuscript was not submitted to more than one journal for simultaneous consideration. Also, the submitted work was original and has not been published elsewhere in any form or language.

Consent to participate

It is confirmed that all the authors are aware and satisfied of the authorship order and correspondence of the paper.

Consent for publication

The publisher has the permission of the authors to publish the given article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guía-Hernández, L.A., Ochoa-Palacios, R.M., Reséndiz-Flores, E.O. et al. Optimization of submerged arc welding parameters to improve corrosion resistance and hardness in API 5L X70 steel joins using Support Vector Regression and Multi-Objective Genetic Algorithm. Int J Adv Manuf Technol 126, 531–541 (2023). https://doi.org/10.1007/s00170-023-11070-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11070-4