Abstract

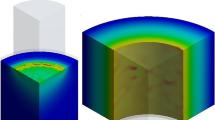

To investigate the forming law of an electrolytically modified surface at the intersection of cross holes and predict the radius of transition arc accurately, the numerical solution and data fitting method were conducted. The numerical solution of electrolytic repair under different machining voltages, times, and gaps is carried out on the basis of the established transition arc machining model at the intersection of ECM cross holes. Boundary point is then fitted using least squares method to obtain the radius value of transition arc. Anodic dissolution regression equation R (U, t, θ) is subsequently obtained by fitting transition arc radius values corresponding to each group of processing parameters. Finally, the regression equation is revised according to the test results to approximate real test data. The regression equation R (U, t, θ) presents a high fitting degree (\({\text{R}}_{\text{s}}^{2}\) = 0.96) after calculation. The three-dimensional model of the electrolytically modified surface at the intersection of cross holes can intuitively show the change of the transition arc, and the prediction error of the regression equation RM (U, t, θ) corrected with test data is reduced to 10.82%. Inputting different processing parameters can accurately predict the corresponding transition arc radius value, reduce the test workload, and guide the parameter selection of the actual process test with the modified anodic dissolution regression equation RM (U, t, θ).

Similar content being viewed by others

Data availability

All data and material are true and valid, available.

Code availability

Not applicable.

References

Oguz H, Ogut H, Aydin F, Ciniviz M, Eryilmaz T (2019) Investigation of engine performance and kit design for the usage of safflower oil as in diesel engine. Renew Energy 143:692–702

Scolaro E, Beligoj M, Estevez MP, Alberti L, Renzi M, Mattetti M (2021) Electrification of agricultural machinery: a review. IEEE Access 9:164520–164541

Tuccar G, Uludamar E (2018) Emission and engine performance analysis of a diesel engine using hydrogen enriched pomegranate seed oil biodiesel. Int J Hydrog Energy 43:18014–18019

Liang X, Zheng Z, Zhang H, Wang Y, Yu H (2019) A review of early injection strategy in premixed combustion engines. Appl Sci-Basel 9:3737

Payri R, Salvador F J, Carreres M, Belmar-Gil M (2020) Thermal effects on the diesel injector performance through adiabatic 1D modelling. Part II: model validation, results of the simulations and discussion. Fuel 260:115663

Hu C, He L, Chen Y, Zhao B, Jun D, Qu MJ (2021) Electrical and optical characterizations of a rotating gliding arc plasma-enhanced combustion dome in an aero-engine combustor. J Phys D Appl Phys 54:205202

Fransen S, Fransaer J, Kuhn S (2018) Current and concentration distributions in electrochemical microreactors: numerical calculations and asymptotic approximations for self-supported paired synthesis. Electrochim Acta 292:914–934

Wang D, Zhu Z, Wang H, Zhu D (2016) Convex shaping process simulation during counter-rotating electrochemical machining by using the finite element method. Chin J Aeronaut 29:534–541

Wosiak G, Da Silva J, Sena SS, De Andrade RN, Pereira E (2022) CFD simulation and experimental comparison of bubble-induced convection during electrochemical water splitting. Chem Eng J 433:133194

Zhang M, Wang JY, Cai YB, Jiao CS, Adede SO, Zhu CM (2019) Electroanalytical and electrodeposited simulation of Ce3+ in molten LiCl-KCl. J Electrochem Soc 166:D868–D874

Read TL, Bitziou E, Joseph MB, Macpherson JV (2014) In situ control of local pH using a boron doped diamond ring disk electrode: optimizing heavy metal (mercury) detection. Anal Chem 86:367–371

Pan Z, Chan WP, Veksha A, Giannis A, Dou XM, Wang HM, Lisak G, Lim TT (2019) Thermodynamic analyses of synthetic natural gas production via municipal solid waste gasification, high-temperature water electrolysis and methanation. Energy Conv Manag 202

Goel H, Rath U, Pandey PM (2019) Modelling and simulation of ultrasonic-assisted jet electrochemical micro drilling process. Proc Inst Mech Eng Part C-J Eng Mech Eng Sci 233:4199–4212

Wu M, Liu JW, He JF, Chen XL, Guo ZN (2020) Fabrication of surface microstructures by mask electrolyte jet machining. Int J Mach Tools Manuf 148:103471

Illera M, Lostado R, Martinez RF, Mac Donald BJ (2014) Characterization of electrolytic tinplate materials via combined finite element and regression models. J Strain Anal Eng Des 49:467–480

Prasad YVRK, Rao KP (2011) Materials modeling and finite element simulation of isothermal forging of electrolytic copper. Mater Des 32:1851–1858

Hou WY, Li HS, Li M, Zhang B, Wang YJ, Gao YT (2019) Multi-physical field coupling numerical investigation of alumina dissolution. Appl Math Model 67:588–604

Sun Z, Cai LW, Ni HO, Lu GM, Yu JG (2018) Coupled electro-thermal field in a high current electrolysis cell or liquid metal batteries. R Soc Open Sci 5:171309

Tang L, Yang WL, Shi CJ, Zhang LF, Zhai KG (2022) Cathode structure optimization and process experiment in electrochemical machining of multi-stage internal cone hole. Int J Adv Manuf Technol 120:3901–3910

Wang TL, Qiu QQ, Jing LW, Zhang XB (2018) Design of circular composite sputtering cathode and simulation of its discharge characteristics. Acta Phys Sin 67:070703

Wang DY, Li JZ, Zhu D (2019) Counter-rotating electrochemical machining of a convex array using a cylindrical cathode tool with multifold angular velocity. J Electrochem Soc 166:E412–E419

Chen GH, Shi KJ, Chu JK, Wu H, Zhou C, Xiao S (2021) Numerical simulation and optimization of cooling flow field of cylindrical cathode with annular magnetic field. Acta Phys Sin 70:075203

Fang M, Chen YL, Jiang LJ, Su YS, Liang Y (2019) Optimal design of cathode based on iterative solution of multi-physical model in pulse electrochemical machining (PECM). Int J Adv Manuf Technol 105:3261–3270

Liu Y, Jiang Y, Guo CS, Deng SH, Kong HH (2018) Experimental research on machining localization and surface quality in micro electrochemical milling of nickel-based superalloy. Micromachines 9:402

Tkacheva O, Arkhipov P, Zaykov Y (2020) Solid phase formation during aluminium electrolysis. Electrochem Commun 110:106624

Xu ZY, Wang YD (2021) Electrochemical machining of complex components of aero-engines: developments, trends, and technological advances. Chin J Aeronaut 34:28–53

Zhang CF, Ai H, Yan Z, Jiang X, Cheng P, Hu Y, Tian H (2020) Cathode optimization and multi-physics simulation of pulse electrochemical machining for small inner-walled ring grooves. Int J Adv Manuf Technol 106:401–416

Patro SK, Mishra DK, Arab J, Dixit P (2020) Numerical and experimental analysis of high-aspect-ratio micro-tool electrode fabrication using controlled electrochemical machining. J Appl Electrochem 50:169–184

Kong QC, Liu GL, Fan XH, Wang ZQ, Li D, Song JL (2019) A nested circle-fitting method for micro-hole centering and its application in electrochemical deburring. Proc Inst Mech Eng Part B-J Eng Manuf 233:2292–2305

Shimasaki T, Kunieda M (2016) Study on influences of bubbles on ECM gap phenomena using transparent electrode. CIRP Ann-Manuf Technol 65:225–228

Tanaka T, Miyazaki K, Yabuki T (2020) Electrolytic bubble nucleation activation in pool boiling of water: heat transfer enhancement and reduction of incipient boiling superheat. Int J Heat Mass Transf 157:119755

Funding

Fundamental Research Funds for the Central Universities (Grant number KYLH2022002); financial support for this work was provided by Jiangsu Agricultural Science and Technology Innovation Fund (Grant number CX (20) 3085).

Author information

Authors and Affiliations

Contributions

Conceptualization, Xiuqing Fu and Zhiwen Jin; methodology, Xiuqing Fu and Hongbiao Wang; software, Xiuqing Fu and Zhiwen Jin; validation, Zhiwen Jin and Qingqing Wang; formal analysis, Qingqing Wang and Xiuqing Fu; investigation, Xiuqing Fu and Zhiwen Jin; resources, Xiuqing Fu and Yifan Zhu; data curation, Zhiwen Jin; writing original draft preparation, Xiuqing Fu and Zhiwen Jin; writing review and editing, Xiuqing Fu and Zhiwen Jin; visualization, Qingqing Wang and Hongbiao Wang; supervision; project administration, Xiuqing Fu and Zhiwen Jin; funding acquisition, Xiuqing Fu and Hongwen Zhang.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fu, X., Jin, Z., Wang, Q. et al. Study on the forming law of electrolytically modified surface at the intersection of cross holes. Int J Adv Manuf Technol 125, 5479–5492 (2023). https://doi.org/10.1007/s00170-023-11058-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11058-0