Abstract

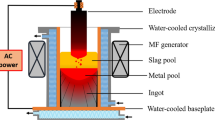

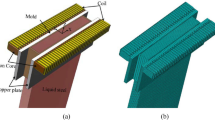

Electromagnetic stirring (EMS) is one of the most used techniques for the preparation of aluminum alloy semi-solid slurry. Compared with other EMS methods, the intermediate frequency electromagnetic stirring (IFEMS) method can achieve the stirring of semi-solid slurry by adjusting the process parameters and realizing the heating of the material. In this study, a 2D symmetric model with coupled magnetic field-flow field simulation was used to study the effects of the input current and input frequency of the induction coil on the magnetic induction intensity and EMS effect in the slurry. The increase of the input current significantly increased the velocity of the slurry at each position but had little effect on the change of the flow direction. The increase of the input frequency improved the stirring effect in some positions of the slurry within a certain range, but the overall intensity of the slurry motion decreased, and the edge effect of the magnetic field and velocity field enhanced. The input current of the induction coil should be less than 100A, and the input frequency should be around 2000 Hz. The experimental platform of the IFEMS was also built to investigate the influence of the input current and stirring time on the microstructure of the prepared samples, and the stirring effects at the center and edge positions of the slurry were compared. Lastly, the microscopic near-spherical structure with an average diameter of 46 μm was obtained using this method, which proved the feasibility of IFEMS for the preparation of aluminum alloy semi-solid slurry.

Similar content being viewed by others

References

Zhao Y (2016) Semi solid forming technology and its application. Appl Technol 2016(8):96–99

Nafari N, Yekani F, Aashuri H (2019) Microstructural investigation of semisolid aluminum A356 alloy prepared by the combination of electromagnetic stirring and gas induction. Solid State Phenom 285:290–295

Flemings MC (1991) Behavior of metal-alloys in the semisolid state. Metall Trans B Process Metall 22(3):269–293

Liao FJ, Wang LD, Zhu DY, Wang QF, Zhang Y (2017) Preparation of aluminum alloy semi-solid slurry by internal cooling process. Special-cast Non-ferrous Alloys 37(11):1208–1211

Pola A, Tocci M, Kapranos P (2018) Microstructure and properties of semi-solid aluminum alloys: a literature review. Metals 8(3):1–17

Mao WM (2012) Research progress of advanced preparation technology for semi-solid metal slurry. Foundry 2012(08):839–855

Kareh K, Lee P, Atwood R, Connolley T, Gourlay C (2014) Revealing the micromechanisms behind semi-solid metal deformation with time-resolved X-ray tomography. Nat Commun 5:4464–4471

Heo M, Jin CK, Roh JS, Kang CG (2020) Investigating the micro-structures of A356 semi-solids based on electromagnetic stirring currents and crucible materials. J Mech Sci Technol 34(9):3807–3813

Zhu YL, Xu XL, Zhao JW, Hu GZ (2021) Effect on microstructure and corrosion resistance of semi-solid slurry of 7A04 aluminum alloy by electromagnetic stirring. Mater Res Express 8(1):16506–16517

Zhang Q, Cao M, Cai J (2015) AlSi9Mg aluminum alloy semi-solid slurry preparation by intermediate frequency electromagnetic oscillation process. J Mater Process Technol 215:42–49

Cheng SJ, Hou H, Zhao YH, Jin YC (2016) Effect of process parameters on the microstructure of semi-solid Zl101 aluminum alloy. Mater Res 19(3):555–561

Bai YL, Xu J, Zhang ZF, Shi LK (2009) Annulus electromagnetic stirring for preparing semisolid A357 aluminum alloy slurry. Trans Nonferrous Met Soc China 19(5):1104–1109

Guan TY, Zhang ZF, Li ZC, Li B, Wang P (2018) Effects of annular electromagnetic stirring melt treatment on microstructure of Al-Zn-Mg-Cu alloy. Special-cast Non-ferrous Alloys 38(8):906–908

He M, Zhang ZF, Mao WM, Xu J, Guan TY, Yang YJ, Li B (2018) Effects of spiral electromagnetic field on multi-physical field and solidification structure of 7075 aluminum alloy in melt treatment process. Special-cast Non-ferrous Alloys 38(10):1045–1049

Liu Z, Chen T, Chen ZP, Liu XM (2019) Two-way slightly electron magnetic stirring and isothermal treatment of A356 aluminum alloy semi-solid slurry. Rare Metal Mater Eng 48(5):1664–1669

Li MJ, Tamura T, Omura N, Murakami YC, Tada SJ (2016) Grain refinement of AZCa912 alloys solidified by an optimized electromagnetic stirring technique. J Mater Process Technol 235:114–120

Qi P, Li BL, Lv WJ, Wang TB, Nie ZR (2017) Effects of electromagnetic stirring frequency on the microstructure and mechanical properties of Al-7Si-0.42 Mg-0.1Cu alloy by semi-solid processing. Mater Sci Forum 898:104–110

Wang Y, Zhao S, Guo Y (2020) Numerical simulation and experimental investigation of the preparation of aluminium alloy 2A50 semi-solid billet by electromagnetic stirring. Materials (Basel) 13(23):1–22

Chen Y, Zhu MY (2009) Simulationon flow field and temperature field of molten steel in bloom mold with ems. Iron Steel Vanadium Titanium 30(4):55–59

Wang H, Zhou JX, Yin YJ (2015) Numerical simulation of heat transfer behavior during aluminum alloys induction melting aluminum alloys induction melting. Special-cast Non-ferrous Alloys 35(8):820–823

Liu H, Zhu SY, Li HB (2016) Magnetic-flow coupled field numerical simulation of electromagnetic stirring in medium frequency furnace. Hot Work Technol 45(11):110–113

Zhou NJ, Yuan LW, Zhou SH, Zhang JQ, Huang Q (2011) Simulation of magnetic field in aluminum melting furnace with electromagnetic stirring. J Cent S Univ (Sci Technol) 42(10):3195–3200

Funding

The authors are grateful for the support of the National Natural Science Foundation of China (Project No. 51875441), the Fundamental Research Funds for the Central Universities (No. zrzd2017027), and the research funds from Shaanxi Provincial Land Engineering Construction Group.

Author information

Authors and Affiliations

Contributions

Yukai Chen: methodology, simulation, test operation, writing-original draft. Miao Cao: conceptualization, resources, test operation. Hao Li: test operation, data analysis. Yin Wang: writing review and editing. Qi Zhang: project administration, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Y., Cao, M., Li, H. et al. Multi-physics coupling simulation investigation of semi-solid A380 aluminum alloy during intermediate frequency electromagnetic stirring process. Int J Adv Manuf Technol 125, 4329–4339 (2023). https://doi.org/10.1007/s00170-023-11027-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11027-7