Abstract

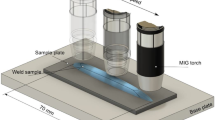

This paper presents the uncertainty quantification (UQ) framework with a data-driven approach using experimental data in wire + arc additive manufacturing (WAAM). This framework consists of four steps. First, the experimental data, including process parameters and signatures, are obtained by performing tests in various conditions. Next, the model is constructed by surrogate modeling or a machine learning algorithm using the obtained data. Then, the uncertainties in a quantity of interest (QoI), such as bead geometry, surface roughness, microstructure, or mechanical properties, are quantified. Lastly, the UQ is verified and validated using the experimental data. The proposed framework is demonstrated with the data-driven UQ of the bead geometry on the bead-on-plate in gas tungsten arc welding (GTAW)-based WAAM. In this case study, the uncertainty sources are process parameters and signatures, and the QoI is bead geometry. The process parameters are wire feed rate (WFR), travel speed (TS), and current, while the process signatures are voltage-related features. The bead geometry includes the width and height of single-layer single bead. The results of the case study has revealed that (1) verifying and validating the data-driven UQ of bead geometry with the normal beads is conducted, and the predicted values are within the 99% confidence intervals, (2) the bead width is negatively correlated with TS, and (3) the bead height has a positive and negative correlation with WFR and TS, respectively.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Tennøe S, Halnes G, Einevoll GT (2018) Uncertainpy: a Python toolbox for uncertainty quantification and sensitivity analysis in computational neuroscience. Front Neuroinformatics 12:49. https://doi.org/10.3389/fninf.2018.00049

Shridhar K, Laumann F, Liwicki M (2019) A comprehensive guide to bayesian convolutional neural network with variational inference. arXiv preprint arXiv:1901.02731. https://doi.org/10.48550/arXiv.1901.02731

Hu Z, Mahadevan S (2017) Uncertainty quantification and management in additive manufacturing: current status, needs, and opportunities. Int J Adv Manuf Technol 93(5):2855–2874. https://doi.org/10.1007/s00170-017-0703-5

Hamdia KM, Msekh MA, Silani M, Vu-Bac N, Zhuang X, Nguyen-Thoi T, Rabczuk T (2015) Uncertainty quantification of the fracture properties of polymeric nanocomposites based on phase field modeling. Compos Struct 133:1177–1190. https://doi.org/10.1016/j.compstruct.2015.08.051

Nath P, Hu Z, Mahadevan S (2018) Modeling and uncertainty quantification of material properties in additive manufacturing. In: Proceedings of 2018 AIAA Non-Deterministic Approaches Conference. p 0923. https://doi.org/10.2514/6.2018-0923

Roy M, Wodo O (2020) Data-driven modeling of thermal history in additive manufacturing. Addit Manuf 32:101017. https://doi.org/10.1016/j.addma.2019.101017

Wang Z, Liu P, Hu Z, Chen L (2019) Simulation-based process optimization of metallic additive manufacturing under uncertainty. Int Des Eng Tech Conf Comput Inf Eng Conf 59186:V02AT03A030. https://doi.org/10.1115/DETC2019-97492

Kapusuzoglu B, Mahadevan S (2020) Physics-informed and hybrid machine learning in additive manufacturing: application to fused filament fabrication. Jom 72(12):4695–4705. https://doi.org/10.1007/s11837-020-04438-4

Guo M, Brune C (2021) Uncertainty quantification for physics-informed deep learning. In: Mathematics: Key Enabling Technology for Scientific Machine Learning. p 47–51.

Wang Z, Liu P, Ji Y, Mahadevan S, Horstemeyer MF, Hu Z, Chen L, Chen LQ (2019) Uncertainty quantification in metallic additive manufacturing through physics-informed data-driven modeling. Jom 71(8):2625–2634. https://doi.org/10.1007/s11837-019-03555-z

Wang Z, Liu P, Xiao Y, Cui X, Hu Z, Chen L (2019) A data-driven approach for process optimization of metallic additive manufacturing under uncertainty. J Manuf Sci Eng 141(8):081004. https://doi.org/10.1115/1.4043798

Zhang Y, Moon SK (2021) Data-driven design strategy in fused filament fabrication: status and opportunities. J Comput Des Eng 8(2):489–509. https://doi.org/10.1093/jcde/qwaa094

Mozaffar M, Paul A, Al-Bahrani R, Wolff S, Choudhary A, Agrawal A, Kornel E, Cao J (2018) Data-driven prediction of the high-dimensional thermal history in directed energy deposition processes via recurrent neural networks. Manuf Lett 18:35–39. https://doi.org/10.1016/j.mfglet.2018.10.002

Wang Z, Jiang C, Liu P, Yang W, Zhao Y, Horstemeyer M, Chen L, Hu Z, Chen L (2020) Uncertainty quantification and reduction in metal additive manufacturing. NPJ Comput Mater 6(1):1–10. https://doi.org/10.1038/s41524-020-00444-x

Hashemi SM, Parvizi S, Baghbanijavid H, Tan AT, Nematollahi M, Ramazani A, Fang N, Elahinia M (2022) Computational modelling of process–structure–property–performance relationships in metal additive manufacturing: a review. Int Mater Rev 67(1):1–46. https://doi.org/10.1080/09506608.2020.1868889

Lee SH (2020) Optimization of cold metal transfer-based wire arc additive manufacturing processes using gaussian process regression. Metals 10(4):461. https://doi.org/10.3390/met10040461

Barnes J, Kingsbury A, Bono E (2016) Does low cost titanium powder yield low cost titanium parts. In: Proceedings of PowderMet 2016 international conference on powder metallurgy. Boston, MA

Kim DB, Witherell P, Lu Y, Feng S (2017) Toward a digital thread and data package for metals-additive manufacturing. Smart Sustain Manuf Syst 1(1):75. https://doi.org/10.1520/SSMS20160003

Seo G, Ahsan MR, Lee Y, Shin JH, Park H, Kim DB (2021) A functional modeling approach for quality assurance in metal additive manufacturing. Rapid Prototyp J 27(2):288–303. https://doi.org/10.1108/RPJ-12-2018-0312

Olson GB (1997) Computational design of hierarchically structured materials. Science 277(5330):1237–1242. https://doi.org/10.1126/science.277.5330.1237

Olson GB (2001) Brains of steel: mind melding with materials. Int J Eng Educ 17(4/5):468–471

McDowell DL, Olson GB (2008) Concurrent design of hierarchical materials and structures. In: Yip S, Rubia T (eds) Scientific modeling and simulations. Springer, Dordrecht, pp 207–240

Huang DJ, Li H (2021) A machine learning guided investigation of quality repeatability in metal laser powder bed fusion additive manufacturing. Mater Des 203:109606. https://doi.org/10.1016/j.matdes.2021.109606

Lopez F, Witherell P, Lane B (2016) Identifying uncertainty in laser powder bed fusion additive manufacturing models. J Mech Des 138(11):114502. https://doi.org/10.1115/1.4034103

Tang S, Wang G, Song H, Li R, Zhang H (2021) A novel method of bead modeling and control for wire and arc additive manufacturing. Rapid Prototyp J 27:311–320. https://doi.org/10.1108/RPJ-05-2020-0097

Kats D, Wang Z, Gan Z, Liu WK, Wagner GJ, Lian Y (2022) A physics-informed machine learning method for predicting grain structure characteristics in directed energy deposition. Comput Mater Sci 202:110958. https://doi.org/10.1016/j.commatsci.2021.110958

Mondal B, Mukherjee T, DebRoy T (2022) Crack free metal printing using physics informed machine learning. Acta Mater 226:117612. https://doi.org/10.1016/j.actamat.2021.117612

Schwalbach EJ, Donegan SP, Chapman MG, Chaput KJ, Groeber MA (2019) A discrete source model of powder bed fusion additive manufacturing thermal history. Addit Manuf 25:485–498. https://doi.org/10.1016/j.addma.2018.12.004

Singh SR, Khanna P (2021) Wire arc addtivie menufacturing (WAAM): A new process to shape engineering materials. Mater Today: Proc 44:118–128. https://doi.org/10.1016/j.matpr.2020.08.030

Rosli NA, Alkahari MR, Bin Abdollah MF, Maidin S, Ramli FR, Herawan SG (2021) Review on effect of heat input for wire arc additive manufacturing process. J Mater Res Technol 11:2127–2145. https://doi.org/10.1016/j.jmrt.2021.02.002

Ding D, Pan Z, Cuiuri D, Li H, Van Duin S, Larkin N (2016) Bead modelling and implementation of adaptive MAT path in wire and arc additive manufacturing. Robot Comput-Integr Manuf 39:32–42. https://doi.org/10.1016/j.rcim.2015.12.004

Ding D, Pan Z, Cuiuri D, Li H, Larkin N (2016) Adaptive path planning for wire-feed additive manufacturing using medial axis transformation. J Clean Prod 133:942–952. https://doi.org/10.1016/j.jclepro.2016.06.036

Ding D, Pan Z, Dominic C, Li H (2015) A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures. Robot Comput-Integr Manuf 34:8–19. https://doi.org/10.1016/j.rcim.2015.01.003

Ding D, Pan Z, Cuiuri D, Li H (2015) Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int J Adv Manuf Technol 81:465–481. https://doi.org/10.1007/s00170-015-7077-3

Tanvir M, Ahsan R, Ji C, Hawkins W, Bates B, Kim D (2019) Heat treatment effects on Inconel 625 components fabricated by wire+ arc additive manufacturing (WAAM)—part 1: microstructural characterization. Int J Adv Manuf Technol 103(9):3785–3798. https://doi.org/10.1007/s00170-019-03828-6

Lee C, Seo G, Kim D, Kim M, Shin J (2021) Development of defect detection AI model for wire+ arc additive manufacturing using high dynamic range images. Appl Sci 11(16):7541. https://doi.org/10.3390/app11167541

Cho HW, Shin SJ, Seo GJ, Kim DB, Lee DH (2022) Real-time anomaly detection using convolutional neural network in wire arc additive manufacturing: molybdenum material. J Mater Process Technol 302:117495. https://doi.org/10.1016/j.jmatprotec.2022.117495

Nath P, Hu Z, Mahadevan S (2017) Mutli-level uncertainty quantification in additive manufacturing. In: Proceedings of 2017 International Solid Freeform Fabrication Symposium, University of Texas at Austin. p 922–937. https://hdl.handle.net/2152/89891

Hu Z, Mahadevan S (2017) Uncertainty quantification in prediction of material properties during additive manufacturing. Scripta Mater 135:135–140. https://doi.org/10.1016/j.scriptamat.2016.10.014

Tian C, Li T, Bustillos J, Bhattacharya S, Turnham T, Yeo J, Moridi A (2021) Data-driven approaches toward smarter additive manufacturing. Adv Intell Syst 3(12):2100014. https://doi.org/10.1002/aisy.202100014

Ding D, Pan Z, Cuiuri D, Li H (2015) A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot Comput-Integr Manuf 31:101–110. https://doi.org/10.1016/j.rcim.2014.08.008

Li Y, Sun Y, Han Q, Zhang G, Horváth I (2018) Enhanced beads overlapping model for wire and arc additive manufacturing of multi-layer multi-bead metallic parts. J Mater Process Technol 252:838–848. https://doi.org/10.1016/j.jmatprotec.2017.10.017

Lambiase F, Scipioni SI, Paoletti A (2022) Accurate prediction of the bead geometry in wire arc additive manufacturing process. Int J Adv Manuf Technol 119:7629–7639. https://doi.org/10.1007/s00170-021-08588-w

Veiga F, Suarez A, Aldalur E, Artaza T (2022) Wire arc additive manufacturing of invar parts: Bead geometry and melt pool monitoring. Measurement 189:110452. https://doi.org/10.1016/j.measurement.2021.110452

Xue Q, Ma S, Liang Y, Wang J, Wang Y, He F, Liu M (2018) Weld bead geometry prediction of additive manufacturing based on neural network. In: Proceedings of 2018 11th International Symposium on Computational Intelligence and Design. p 47–51. https://doi.org/10.1109/ISCID.2018.10112

Dinovitzer M, Chen X, Laliberte J, Huang X, Frei H (2019) Effect of wire and arc additive manufacturing (WAAM) process parameters on bead geometry and microstructure. Addit Manuf 26:138–146. https://doi.org/10.1016/j.addma.2018.12.013

Cho J, Lee D, Seo G, Kim D, Shin S (2022) Optimizing the mean and variance of bead geometry in the wire+arc additive manufacturing using a desirability function method. Int J Adv Manuf Technol 120:7771–7783. https://doi.org/10.1007/s00170-022-09237-6

Frazier WE (2014) Metal additive manufacturing: a review. J Mater Eng Perform 23(6):1917–1928. https://doi.org/10.1007/s11665-014-0958-z

Lewandowski JJ, Seifi M (2016) Metal additive manufacturing: a review of mechanical properties. Annu Rev Mater Res 46:151–186. https://doi.org/10.1146/annurev-matsci-070115-032024

Xia C, Pan Z, Polden J, Li H, Xu Y, Chen S (2022) Modeling and prediction of surface roughness in wire arc additive manufacturing using machine learning. J Intell Manuf 33:1467–1482. https://doi.org/10.1007/s10845-020-01725-4

Xiong J, Li Y, Li R, Yin Z (2018) Influences of process parameters on surface roughness of multi-layer single-pass thin-walled parts in GMAW-based additive manufacturing. J Mater Process Technol 252:128–136. https://doi.org/10.1016/j.jmatprotec.2017.09.020

Yildiz A, Davut K, Koc B, Yilmaz O (2020) Wire arc additive manufacturing of high-strength low alloy steels: study of process parameters and their influence on the bead geometry and mechanical characteristics. Int J Adv Manuf Technol 108:3391–3404. https://doi.org/10.1007/s00170-020-05482-9

Elsokaty A, Oraby O, Sadek S, Salem H (2023) Influence of wire arc additive manufacturing beads’ geometry and building strategy: mechanical and structural behavior of ER70S-6 prismatic blocks. J Manuf Mater Process 7:3. https://doi.org/10.3390/jmmp7010003

Hauser T, Reisch R, Breese P, Lutz B, Pantano M, Nalam Y, Bela K, Kamps T, Volpp J, Kaplan A (2021) Porosity in wire arc additive manufacturing of aluminium alloys. Addit Manuf 41:101993. https://doi.org/10.1016/j.addma.2021.101993

Wang Z, Yang W, Liu Q, Zhao Y, Liu P, Wu D, Mihaela B, Chen L (2022) Data-driven modeling of 2.2 and property in additive manufacturing: a review and future directions. J Manuf Process 77:13–31. https://doi.org/10.1016/j.jmapro.2022.02.053

Yang XS (2020) Nature-inspired optimization algorithms. Academic Press

Chau T, Burovskiy P, Flynn M, Luk W (2017) Advances in dataflow systems. In A. Hurson, V. Milutinović (Eds.). Adv Comput 106:21–62. https://doi.org/10.1016/bs.adcom.2017.04.002. (Elsevier)

Oh Y, Sharp M, Sprock T, Kwon S (2021) Neural network-based build time estimation for additive manufacturing: a performance comparison. J Comput Des Eng 8(5):1243–1256. https://doi.org/10.1093/jcde/qwab044

Francis J, Bian L (2019) Deep learning for distortion prediction in laser-based additive manufacturing using big data. Manuf Lett 20:10–14. https://doi.org/10.1016/j.mfglet.2019.02.001

Chen YC (2017) A tutorial on kernel density estimation and recent advances. Biostat Epidemiol 1(1):161–187. https://doi.org/10.1080/24709360.2017.1396742

Gramacki A (2018) Nonparametric kernel density estimation and its computational aspects, vol 37. Springer International Publishing, Cham

Malato G (2021) How to calculate confidence intervals in Python. https://towardsdatascience.com/how-to-calculate-confidence-intervals-in-python-a8625a48e62b. Accessed 7 June 2022

Saksh (2021) Calculate confidence interval in Python (with examples). https://vedexcel.com/how-to-calculate-confidence-intervals-in-python/. Accessed 7 June 2022

Liang B (2010) Error and uncertainty quantification and sensitivity analysis in mechanics computational models. MS dissertation. Vanderbilt University, Nashville

Liang B, Mahadevan S (2011) Error and uncertainty quantification and sensitivity analysis in mechanics computational models. Int J Uncertain Quantif 1(2):147–161. https://doi.org/10.1615/Int.J.UncertaintyQuantification.v1.i2.30

Sobol IM (1993) Sensitivity analysis for non-linear mathematical models. Math Model Comput Exp 1:407–414

Archer GEB, Saltelli A, Sobol IM (1997) Sensitivity measures, ANOVA-like techniques and the use of bootstrap. J Stat Comput Simul 58(2):99–120. https://doi.org/10.1080/00949659708811825

Saltelli A, Annoni P, Azzini I, Campolongo F, Ratto M, Tarantola S (2010) Variance based sensitivity analysis of model output. Design and estimator for the total sensitivity index. Comput Phys Commun 181(2):259–270. https://doi.org/10.1016/j.cpc.2009.09.018

Sobol IM (2001) Global sensitivity indices for nonlinear mathematical models and their Monte Carlo estimates. Math Comput Simul 55(1–3):271–280. https://doi.org/10.1016/S0378-4754(00)00270-6

Oberkampf WL, Roy CJ (2010) Verification and validation in scientific computing. Cambridge University Press

Oden T, Moser R, Ghattas O (2010) Computer predictions with quantified uncertainty, part I. SIAM News 43(9):1–3

Riedmaier S, Danquah B, Schick B, Diermeyer F (2021) Unified framework and survey for model verification, validation and uncertainty quantification. Arch Comput Methods Eng 28(4):2655–2688. https://doi.org/10.1007/s11831-020-09473-7

Flood A, Liou F (2018) Review of metal AM simulation validation techniques. J Mech Eng Autom 8:43–52. https://doi.org/10.17265/2159-5275/2018.02.001

Geng H, Xiong J, Huang D, Lin X, Li J (2017) A prediction model of layer geometrical size in wire and arc additive manufacture using response surface methodology. Int J Adv Manuf Technol 93(1):175–186. https://doi.org/10.1007/s00170-015-8147-2

Kim J, Seo G, Kim D, Shin J, Park H (2021) Machine learning models for detecting weld bead defects in wire-arc additive manufacturing. Korean J Comput Des Eng 26(2):131–143. https://doi.org/10.7315/CDE.2021.131

Hexagon (2022) PC-DMIS. https://www.hexagonmi.com/products/software/pc-dmis. Accessed 7 June 2022

CloudCompare (2022) 3D point cloud and mesh processing software. https://www.danielgm.net/cc/. Accessed 7 June 2022

Xiong J, Zhang G, Hu J, Wu L (2014) Bead geometry prediction for robotic GMAW-based rapid manufacturing through a neural network and a second-order regression analysis. J Intell Manuf 25:157–163. https://doi.org/10.1007/s10845-012-0682-1

Ding D, Shen C, Pan Z, Cuiuri D, Li H, Larkin N, Duin S (2016) Towards an automated robotic arc-welding-based additive manufacturing system from CAD to finished part. Comput Aided Des 73:66–75. https://doi.org/10.1016/j.cad.2015.12.003

Herman J, Usher W (2017) SALib: an open-source Python library for sensitivity analysis. J Open Source Softw 2(9):97. https://doi.org/10.21105/joss.00097

Debroy T, Zhang W, Turner J, Babu SS (2017) Building digital twins of 3D printing machines. Scripta Mater 135:119–124. https://doi.org/10.1016/j.scriptamat.2016.12.005

Hussein RO, Nie X, Northwood DO (2013) Processing-structure-properties-performance relationships for Mg-alloys coated using plasma electrolytic oxidation (PEO) Method. In: Material Forum Vol 37

Mahadevan S, Nath P, Hu Z (2022) Uncertainty quantification for additive manufacturing process improvement: recent advances. ASCE-ASME J Risk Uncertain Eng Syst, Part B: Mech Eng 8:010801. https://doi.org/10.1115/1.4053184

Srivastava M, Rathee S, Tiwaru A, Dongre M (2023) Wire arc additive manufacturing of metals: a review on processes, materials and their behavior. Mater Chem Phys 294:126988. https://doi.org/10.1016/j.matchemphys.2022.126988

Zhang J, Wang P, Gao R (2019) Deep learning-based tensile strength prediction in fused deposition modeling. Comput Ind 107:11–21. https://doi.org/10.1016/j.compind.2019.01.011

Hönnige J, Seow C, Ganguly S, Xu X, Cabeza S, Coules H, Williams S (2021) Study of residual stress and microstructural evolution in as-deposited and inter-pass rolled wire plus arc additively manufactured Inconel 718 alloy after ageing treatment. Mater Sci Eng: A 801:140368. https://doi.org/10.1016/j.msea.2020.140368

Jafari D, Vaneker T, Gibson I (2021) Wire and arc additive manufacturing: opportunities and challenges to control the quality and accuracy of manufactured parts. Mater Des 202:109471. https://doi.org/10.1016/j.matdes.2021.109471

Chen S, Gao H, Zhang Y, Wu Q, Gao Z, Zhou X (2022) Review on residual stresses in metal additive manufacturing: formation mechanisms, parameter dependencies, prediction and control approaches. J Market Res 17:2950–2974. https://doi.org/10.1016/j.jmrt.2022.02.054

Nath P, Olson J, Mahadevan S, Lee Y (2020) Optimization of fused filament fabrication process parameters under uncertainty to maximize part geometry accuracy. Addit Manuf 35:101331. https://doi.org/10.1016/j.addma.2020.101331

Knapp GL, Mukherjee T, Zuback JS, Wei HL, Palmer TA, De A, DebRoy T (2017) Building blocks for a digital twin of additive manufacturing. Acta Mater 135:390–399. https://doi.org/10.1016/j.actamat.2017.06.039

Mukherjee T, DebRoy T (2019) A digital twin for rapid qualification of 3D printed metallic components. Appl Mater Today 14:59–65. https://doi.org/10.1016/j.apmt.2018.11.003

Gunasegaram DR, Murphy AB, Matthews MJ, DebRoy T (2021) The case for digital twins in metal additive manufacturing. J Phys: Mater 4(4):040401. https://doi.org/10.1088/2515-7639/ac09fb

Kim D, Shao G, Jo G (2022) A digital twin implementation architecture for wire + arc additive manufacturing based on ISO 23247. Manuf Lett 34:1–5. https://doi.org/10.1016/j.mfglet.2022.08.008

Funding

This research was supported by the MSIT (Ministry of Science and ICT), Korea, under the High-Potential Individuals Global Training Program (2021–0-01566), supervised by the IITP (Institute of Information and Communications Technology Planning & Evaluation).

Author information

Authors and Affiliations

Contributions

Junhee Lee preprocessed the real experimental data of wire + arc additive manufacturing; constructed the models; carried out the uncertainty quantification, the global sensitivity analysis, and the analysis of variance; and wrote an original first draft of this paper. Sainand Jadhav conducted experiments on the gas-tungsten arc welding-based wire + arc additive manufacturing. Duck Bong Kim provided the real experimental data of wire + arc additive manufacturing, helped to organize the contents of the writing, and commented on the draft. Kwanghee Ko reviewed and edited the draft of the paper. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The submitted work is original, complete, and has not been accepted/published elsewhere in any form or language.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, J., Jadhav, S., Kim, D.B. et al. Preliminary results for a data-driven uncertainty quantification framework in wire + arc additive manufacturing using bead-on-plate studies. Int J Adv Manuf Technol 125, 5519–5540 (2023). https://doi.org/10.1007/s00170-023-11015-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11015-x