Abstract

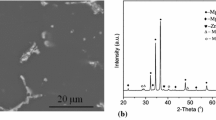

The rise of machine learning (ML) has taken materials development into a radically distinct realm. In this study, a framework based on ML and rate-dependent crystal plasticity finite elements were established to predicted flow stress and texture evolution of Inconel 740H alloy under uniaxial compression. First, the initial characterization data were used to construct a representative volume unit (RVE) model with an approximate structure to the real material microstructure, and then, the crystal plasticity finite element method (CPFEM) and its verification were carried out. Second, the dataset obtained from CPFEM and experimental data were used as training and test sets for the genetic algorithm optimized neural network (GA-BP) model. The results indicated that the proposed framework can well describe the macroscopic and microscopic response of Inconel 740H during uniaxial compression, which was in line with the experimental findings. Moreover, the GA-BP model had higher prediction accuracy and better prediction performance than the CPFE model; the root-mean-square error (RMSE) and mean square correlation coefficient (R2) of stress and texture were 0.46156, 0.99282 and 2.7567, 0.9655, respectively. It is clear that the GA-BP is more efficient than the physical mechanism based CPFE model.

Similar content being viewed by others

Data availability

The authors confirm that the data and material supporting the findings of this work are available within the article.

References

Chong Y, Liu ZD, Godfrey A, Liu W, Weng YQ (2014) Microstructure evolution and mechanical properties of Inconel 740H during aging at 750 °C. Mat Sci Eng A-Struct 589:153–164. https://doi.org/10.1016/j.msea.2013.09.076

Evans ND, Maziasz PJ, Swindeman RW, Smith GD (2004) Microstructure and phase stability in INCONEL alloy 740 during creep. Scr Mater 51:503–507. https://doi.org/10.1016/j.scriptamat.2004.05.047

Zhao S, Xie X, Smith GD (2006) Research and improvement on structure stability and corrosion resistance of nickel-base superalloy INCONEL alloy 740. Mater Des 27:1120–1127. https://doi.org/10.1016/j.matdes.2005.03.015

Hill R, Rice RJ (1972) Constitutive analysis of elastic-plastic crystals at arbitrary strain. J Mech Phys Solids 20:401–413. https://doi.org/10.1016/0022-5096(72)90017-8

Huang SY, Zhang SR, Yong LD, Peng YH (2011) Simulation of texture evolution during plastic deformation of FCC, BCC and HCP structured crystals with crystal plasticity based finite element method. T Nonferr Metal Soc 21:1817–1825. https://doi.org/10.1016/S1003-6326(11)60936-9

Chandra S, Samal MK, Kumar NN, Chavan VM (2021) Simulation of Hall-Petch effect in alloy 690 using crystal plasticity model considering effect of grain boundaries. Mater Lett 297:129915. https://doi.org/10.1016/j.matlet.2021.129915

Qian Y, Fan Q, Liu X, Wang D, Zhou Y (2020) Crystal plasticity finite element method for slip systems evolution analysis of α/β duplex titanium alloys during quasi-static tensile testing. Appl Sci 10:7782. https://doi.org/10.3390/app10217782

Li YZ, Huang MX (2021) A dislocation-based flow rule with succinct power-law form suitable for crystal plasticity finite element simulations. Int J Plasticity 138:102921. https://doi.org/10.1016/j.ijplas.2020.102921

Zhao M, Ji X, Liang SY (2019) Force prediction in micro-grinding maraging steel 3J33b considering the crystallographic orientation and phase transformation. Int J Adv Manuf Technol 103:2821–2836. https://doi.org/10.1007/s00170-019-03724-z

Zhang C, Xu YJ, Zhang LW, Zhou XG (2020) Crystal plasticity analysis of the relation between micro-texture and surface ridging for a 21%Cr ferritic stainless steel. Steel Res Int 91:2000109. https://doi.org/10.1002/srin.202000109

Liu JQ, Huang MS, Li ZH, Zhao L, Zhu YX (2021) Microvoid growth mechanism in FCC polycrystals and a statistical damage model. Int J Plast 137:102888. https://doi.org/10.1016/j.ijplas.2020.102888

Hu L, Jiang SY, Tu J, Zhou ZM (2019) Subgrain effect on grain scale plasticity of NiTi shape memory alloy under canning compression: a crystal plasticity finite element analysis. Met Mater Int 25:333–342. https://doi.org/10.1007/s12540-018-0178-4

Min KM, Jeong W, Hong SH, Lee CA, Cha PR, Han HN, Lee MG (2020) Integrated crystal plasticity and phase field model for prediction of recrystallization texture and anisotropic mechanical properties of cold-rolled ultra-low carbon steels. Int J Plast 127:102644. https://doi.org/10.1016/j.ijplas.2019.102644

Lefik M, Schrefler BA (2003) Artificial neural network as an incremental non-linear constitutive model for a finite element code. Comput Meth Appl Mech Eng 192:3265–3283. https://doi.org/10.1016/S0045-7825(03)00350-5

Zhu YL, Cao Y, Liu CJ, Luo R, Li N, Shu G, Huang GJ, Liu Q (2021) Dynamic behavior and modified artificial neural network model for predicting flow stress during hot deformation of Alloy 925. Mater Today Commun 25:101329. https://doi.org/10.1016/j.mtcomm.2020.101329

Mahalle G, Salunke O, Kotkunde N, Gupta AK, Singh SK (2019) Neural network modeling for anisotropic mechanical properties and work hardening behavior of Inconel 718 alloy at elevated temperatures. J Mater Res Technol 8:2130–2140. https://doi.org/10.1016/j.jmrt.2019.01.019

Luo JT, Zhao JQ, Yang ZY, Jin YB, Zhang CX (2022) Microstructure prediction of multi-directional forging for 30Cr2Ni4MoV steel by the secondary development of Deform software and BP neural network. Int J Adv Manuf Technol 119:2971–2984. https://doi.org/10.1007/s00170-021-08615-w

Koenuma K, Yamanaka A, Watanabe I, Kuwabara T (2020) Estimation of texture-dependent stress-strain curve and r-value of aluminum alloy sheet using deep learning. Mater Trans 61:2276–2283. https://doi.org/10.2320/matertrans.P-M2020853

Dewangan SK, Samal S, Kumar V (2020) Microstructure exploration and an artificial neural network approach for hardness prediction in AlCrFeMnNiWx High-Entropy Alloys. J Alloy Compd 823:153766. https://doi.org/10.1016/j.jallcom.2020.153766

Gui YW, Li QA, Zhu KG, Xue YB (2021) A combined machine learning and EBSD approach for the prediction of 10–12 twin nucleation in an Mg-RE alloy. Mater Today Commun 27:102282. https://doi.org/10.1016/j.mtcomm.2021.102282

Brahme A, Winning M, Raabe D (2009) Prediction of cold rolling texture of steels using an artificial neural betwork. Comp Mater Sci 46:800–804. https://doi.org/10.1016/j.commatsci.2009.04.014

Ji YF, Song LB, Sun J, Peng W, Li HY, Ma LF (2021) Application of SVM and PCA-CS algorithms for prediction of strip crown in hot strip rolling. J Cent South Univ 28:2333–2344. https://doi.org/10.1007/s11771-021-4773-z

Ye WY, Hohl J, Mushongera LT (2022) Prediction of cyclic damage in metallic alloys with crystal plasticity modeling enhanced by machine learning. Mater 22:101388. https://doi.org/10.1016/j.mtla.2022.101388

Ali U, Muhammad W, Brahme A, Skiba O, Inal K (2019) Application of artificial neural networks in micromechanics for polycrystalline metals. Int J Plast 120:205–219. https://doi.org/10.1016/j.ijplas.2019.05.001

Montenegro C, Abolghasem S, Osorio-Pinzon JC, Casas-Rodriguez JP (2020) Microstructure prediction in low and high strain deformation of Al6063 using artificial neural network and finite element simulation. Int J Adv Manuf Technol 106:2101–2117. https://doi.org/10.1007/s00170-019-04704-z

Peirce D, Asaro RJ, Needleman A (1983) Material rate dependence and localized deformation in crystalline solids. Acta Mater 31:1951–1976. https://doi.org/10.1016/0001-6160(83)90014-7

Peirce D, Asaro RJ, Needleman A (1982) An analysis of nonuniform and localized deformation in ductile single crystals. Acta Mater 30:1087–1119. https://doi.org/10.1016/0001-6160(82)90005-0

Asaro RJ (1983) Micromechanics of crystals and polycrystals. Adv Appl Mech 23:1–115. https://doi.org/10.1016/S0065-2156(08)70242-4

Funding

This work is financially supported by the National Natural Science Foundation of China (No. 52005358), the Key R&D Program of Shanxi Province(No.202102020101011), and the Natural Science Foundation of Shanxi Province (No. 201901D111243, 201901D211305).

Author information

Authors and Affiliations

Contributions

Research conception and method design: Yafeng Ji; material preparation, data collection, and analysis: Yaohui Song, Xiaojun Wang; numerical modelling: Xiaojun Wang, Yu Liu; writing (original draft preparation): Xiaojun Wang; writing (review and editing): Yafeng Ji, Huaying Li, Xiao Hu; funding support: Yafeng Ji.

Corresponding author

Ethics declarations

Ethical approval

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent to participate

Not applicable.

Consent for publication

This work is approved by all authors for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Liu, Y., Song, Y. et al. Application of neural network in micromechanical deformation behaviors of Inconel 740H alloy. Int J Adv Manuf Technol 125, 2339–2348 (2023). https://doi.org/10.1007/s00170-023-10908-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-10908-1