Abstract

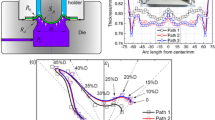

Aluminum alloy thin-walled shells with corner are important components of aircraft lubricating oil tank for protective. The existing process mainly adopts cold stamping combined with manual multi-pass straightening and shape correction. Due to its asymmetrical shape and corner, there are serious defects such as wrinkling and springback during stamping, which restrict the mass production of this kind of products. In this paper, the forming mechanism of defects and the influence of process parameters on it were investigated numerically and experimentally. The results demonstrated that the wrinkling concentrated on the side wall of workpiece was caused by more feeding and metal accumulation in local areas due to stress concentration. There was obvious thinning at the small diameter edge (SDE) of workpiece which can reach 10.0% locally. The springback in different areas of workpiece varied greatly. Massive positive springback occurred at the SDE and the large diameter edge (LDE), and a small amount of negative springback occurred at the top left of the workpiece due to insufficient material extension. The wrinkling and springback can be ameliorated by increasing the blank holder force (BHF) while the thinning will be aggravated. Besides, the increase of friction coefficient and die closing pressure (DCP) can also reduce the wrinkling and springback, respectively. For the workpieces in this paper, the forming defects can be greatly improved within the following process parameters: the BHF of 15 to 20 kN and the stamping speed of not less than 20 mm/s and the DCP of above 350 kN.

Similar content being viewed by others

Data availability

The datasets and material generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Ishchenko YA (2005) High-strength aluminium alloys for welded structures in the aircraft industry. Weld Int 19:173–185. https://doi.org/10.1533/wint.2005.3397

Foster A, Dean TA, Lin J (2009) Process for forming aluminium alloy sheet components. European Patent No EP2324137A1.

Zhou J, Wang B, Lin J, Fu L, Ma W (2014) Forming defects in aluminum alloy hot stamping of side-door impact beam. Trans Nonferrous Metal Soc China 24:3611–3620. https://doi.org/10.1016/S1003-6326(14)63506-8

Meng Q, Wang B, Fu L, Zhou J, Lin J (2012) The influence of process parameters during hot stamping of AA6111 aluminum alloy sheet. Adv Mater Res 572:255–260. https://doi.org/10.4028/www.scientific.net/AMR.572.255

Giuliano G, Samani F (2016) Comparison between superplastic and non-superplastic grade AA5083. J Test Eval 44:2114–2119. https://doi.org/10.1520/JTE20150299

Liu Y, Li J, Wang L, Wang K, Zhu B, Zhang Y (2021) Hot stamping of a B-pillar reinforced panel with 7075 aluminum alloy and the feasibility study of short-time aging. Front Mater 2021:7. https://doi.org/10.3389/fmats.2020.617223

Yang X, Wang B, Zhou J, Dang L, Xiao W, Wang Y (2020) Influence of process parameters on deep drawing of 2060 Al-Li alloy under hot stamping process. Int J Lightweight Mater Manuf 3:36–42. https://doi.org/10.1016/j.ijlmm.2019.09.009

Xu Y, Ke L, Ouyang S, Mao Y, Niu P (2021) Precipitation behavior of intermetallic compounds and their effect on mechanical properties of thick plate friction stir welded Al/Mg joint. J Manuf Process 64:1059–1069. https://doi.org/10.1016/j.jmapro.2020.12.068

Yang X, Chen H, Li M, Bu H, Cai C (2021) Porosity suppressing and grain refining of narrow-gap rotating laser-MIG hybrid welding of 5A06 aluminum alloy. J Manuf Process 68:1100–1113. https://doi.org/10.1016/j.jmapro.2021.06.036

Mori K, Nishijima S, Tan C (2009) Two-stage cold stamping of magnesium alloy cups having small corner radius. Int J Mach Tool Manu 49:767–772. https://doi.org/10.1016/j.ijmachtools.2009.04.005

Gu Z, Li S, Zhao L, Zhu L, Yu G (2019) Finite element simulation and experimental investigations of cold stamping forming defect of A588-A thick weathering steel bogie lower cover. Int J Adv Manuf Tech 104:1275–1283. https://doi.org/10.1007/s00170-019-04148-5

Wang A, Zhong K, Fakir O, Liu J, Dean T (2017) Springback analysis of AA5754 after hot stamping: experiments and FE modelling. Int J Adv Manuf Tech 89:1339–1352. https://doi.org/10.1007/s00170-016-9166-3

Ma W, Wang B, Xiao W, Yang X, Kang Y (2019) Springback analysis of 6016 aluminum alloy sheet in hot V-shape stamping. J Cent South Univ 26:524–535. https://doi.org/10.1007/s11771-019-4024-8

Zhou J, Yang X, Wang B, Xiao W (2021) Springback prediction of 7075 aluminum alloy V-shaped parts in cold and hot stamping. Int J Adv Manuf Tech 119:203–216. https://doi.org/10.21203/rs.3.rs-322846/v1

Zhou J, Wang B, Lin J, Fu L (2013) Optimization of an aluminum alloy anti-collision side beam hot stamping process using a multi-objective genetic algorithm. Arch Civ Mech Eng 13:401–411. https://doi.org/10.1016/j.acme.2013.01.008

Li H, He L, Zhao G, Zhang L (2013) Constitutive relationships of hot stamping boron steel B1500HS based on the modified Arrhenius and Johnson-Cook model. Mater Sci Eng A 580:330–348. https://doi.org/10.1016/j.msea.2013.05.023

Liu S, Wang B, Li W, Liu J (2021) Investigation of cold drawing process of thin-walled ribbed steel tube. J Manuf Process 70:376–388. https://doi.org/10.1016/j.jmapro.2021.08.039

Funding

This work is supported by the Beijing Key Laboratory of Metal Forming Lightweight.

Author information

Authors and Affiliations

Contributions

Jiapeng Wang: conceptualization, investigation, methodology, data curation, writing—original draft, reviewing, and editing.

Jinping Liu: supervision, conceptualization, methodology, resources, funding acquisition, reviewing, and editing.

Bin Wang: supervision, methodology, reviewing, and editing.

Xiaomin Huang: supervision, conceptualization, methodology, reviewing, and editing.

Baoyu Wang: reviewing and editing.

Corresponding authors

Ethics declarations

Ethics approval

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent to participate

Applicable.

Consent for publication

Applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Liu, J., Wang, B. et al. Investigation of forming defects in 5A06 aluminum alloy cold stamping of thin-walled shell with corner. Int J Adv Manuf Technol 125, 2581–2592 (2023). https://doi.org/10.1007/s00170-023-10883-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-10883-7