Abstract

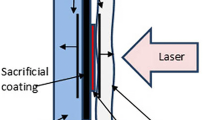

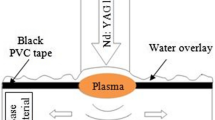

This paper presents a novel hybrid in situ additive manufacturing (AM) method–laser shock forging (LSF), which combines laser shock peening (LSP) with laser melting deposition (LMD). Based on the classical bar-frame model and inherent strain theory, the mechanisms of the effects of pretreatment and posttreatment on AM process have been elaborated for the first time. Towards controlling tensile residual stress (TRS) in the as-built (AB) state of AM parts which has a detrimental effect on their fatigue life, we then developed LSF to introduce tensile inherent strains in LMD built parts in an in situ manner, which will convert TRS to compressive residual stress (CRS). The laser beam used for shock peening can be adjusted to move synchronously with the laser beam used for metal deposition and keep a certain distance, ensuring the laser shock peening to act on the region where the material temperature cools down to the forging temperature range. Then, experimental works have been conducted on 316L stainless steel; residual stress distributions of the AB, LSP, and LSF treated specimens were compared; results show that LSF increases both the magnitude and depth of CRS compared with conventional LSP treatment, thus providing a promising application in enhancing fatigue life in AM process.

Graphical Abstract

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Bartlett JL, Li XD (2019) An overview of residual stresses in metal powder bed fusion. Addit Manuf 27:131–149

Khairallah SA, Anderson A (2014) Mesoscopic simulation model of selective laser melting of stainless steel powder. J Mater Process Tech 214:2627–2636

Loh LE, Chua CK, Yeong WY, Song J, Mapar M, Sing SL, Liu ZH, Zhang DQ (2015) Numerical investigation and an effective modelling on the selective laser melting (SLM) process with aluminium alloy 6061. Int J Heat Mass Transfer 80:288–300

Cheng B, Shrestha S, Chou K (2016) Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit Manuf 12:240–251

Huang Y, Yang LJ, Du XZ, Yang YP (2016) Finite element analysis of thermal behavior of metal powder during selective laser melting. Int J Therm Sci 104:146–157

Prabhakar P, Sames WJ, Dehoff R, Babu BB (2015) Computational modeling of residual stress formation during the electron beam melting process for Inconel 718. Addit Manuf 7:83–91

Yang QC, Zhang P, Cheng L, Min Z, Chyu M, To AC (2016) Finite element modeling and validation of thermomechanical behavior of Ti-6Al-4V in directed energy deposition additive manufacturing. Addit Manuf 12:169–177

Wang JS, Zhang JJ, Liu GT, Liang LJ, Yang G, Huang AG, Pang SY (2022) Effects of scanning strategies on residual stress and deformation by high-power direct energy deposition Island size and laser jump strategy between islands. J Manuf Process 75:23–40

Izadi M, Farzaneh A, Mohammed M, Gibson I, Rolfe B (2020) A review of laser engineered net shaping (LENS) build and process parameters of metallic parts. Rapid Prototyp J 26(6):1059–1078

Liang X, Cheng L, Chen Q, Yang QC, To AC (2018) A modified method for estimating inherent strains from detailed process simulation for fast residual distortion prediction of single-walled structures fabricated by directed energy deposition. Addit Manuf 23:471–486

Vastola G, Zhang G, Pei QX, Zhang YW (2016) Controlling of residual stress in additive manufacturing of Ti6Al4V by finite element modeling. Addit Manuf 12:231–239

Afazov S, Denmark WAD, Toralles BL, Holloway A, Yaghi A (2017) Distortion prediction and compensation in selective laser melting. Addit Manuf 17:15–22

An K, Yuan L, Dial L, Spinelli I, Stoica AD, Gao Y (2017) Neutron residual stress measurement and numerical modeling in a curved thin-walled structure by laser powder bed fusion additive manufacturing. Mater Des 135:122–132

Bugatti M, Semeraro Q (2018) Limitations of the inherent strain method in simulating powder bed fusion processes. Addit Manuf 23:329–346

Chen Q, Liu JK, Liang X, To AC (2020) A level-set based continuous scanning path optimization method for reducing residual stress and deformation in metal additive manufacturing. Comput Method Appl M 360:112719

Liang X, Dong W, Hinnebusch S, Chen Q, Tran HT, Lemon J, Cheng L, Zhou ZK, Hayduke D, To AC (2020) Inherent strain homogenization for fast residual deformation simulation of thin-walled lattice support structures built by laser powder bed fusion additive manufacturing. Addit Manuf 32:101091

Takezawa A, To AC, Chen Q, Liang X, Dugast F, Zhang XP, Kitamura M (2020) Sensitivity analysis and lattice density optimization for sequential inherent strain method used in additive manufacturing process. Comput Method Appl M 370:113231

Chen Q, Taylor H, Takezawa A, Liang X, Jimenez X, Wicker R, To AC (2021) Island scanning pattern optimization for residual deformation mitigation in laser powder bed fusion via sequential inherent strain method and sensitivity analysis. Addit Manuf 46(S1):102116

Dong W, Liang X, Chen Q, Hinnebusch S, Zhou ZK, To AC (2021) A new procedure for implementing the modified inherent strain method with improved accuracy in predicting both residual stress and deformation for laser powder bed fusion. Addit Manuf 47:102345

Liang X, Dong W, Chen Q, To AC (2021) On incorporating scanning strategy effects into the modified inherent strain modeling framework for laser powder bed fusion. Addit Manuf 37:101648

Li YL, Zhou K, Tan PF, Tor SB, Chua CK, Leong KF (2018) Modeling temperature and residual stress fields in selective laser melting. Int J Mech Sci 136:24–35

Parry L, Ashcroft IA, Wildman RD (2016) Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit Manuf 12:1–15

Robinson J, Ashton I, Fox P, Jones E, Sutcliffe C (2018) Determination of the effect of scan strategy on residual stress in laser powder bed fusion additive manufacturing. Addit Manuf 23:13–24

Lv JM, Luo KY, Lu HF, Wang Z, Liu JJ, Lu JZ (2022) Achieving high strength and ductility in selective laser melting Ti-6Al-4V alloy by laser shock peening. J Alloy Compd 899:163335

Jin XY, Lan L, Gao S, He B, Rong YH (2020) Effects of laser shock peening on microstructure and fatigue behavior of Ti-6Al-4V alloy fabricated via electron beam melting. Mater Sci Eng A 780:139199

Lan L, Jin XY, Gao S, He B, Rong YH (2020) Microstructural evolution and stress state related to mechanical properties of electron beam melted Ti-6Al-4V alloy modified by laser shock peening. J Mater Sci Technol 50:153–161

Tong ZP, Pan XY, Zhou WF, Yang Y, Ye YX, Qian DS, Ren XD (2021) Achieving excellent wear and corrosion properties in laser additive manufactured CrMnFeCoNi high-entropy alloy by laser shock peening. Surf Coat Technol 422:127504

Sun RJ, Li LH, Zhu Y, Guo W, Peng P, Cong BQ, Sun JF, Che ZG, Li B, Guo C, Liu L (2018) Microstructure, residual stress and tensile properties control of wire-arc additive manufactured 2319 aluminum alloy with laser shock peening. J Alloy Compd 747:255–265

Guo W, Sun RJ, Song BW, Zhu Y, Li F, Che ZG, Li B, Guo C, Liu L, Peng P (2018) Laser shock peening of laser additive manufactured Ti6Al4V titanium alloy. Surf Coat Technol 349:503–510

Tong ZP, Ren XD, Zhou WF, Adu-Gyamfi S, Chen L, Ye YX, Ren YP, Dai FZ, Yang JD, Li L (2019) Effect of laser shock peening on wear behaviors of TC11 alloy at elevated temperature. Opt Laser Technol 109:139–148

Kalentics N, Boillat E, Peyre P, Ciric-Kostic S, Bogojevic N, Logé RE (2017) Tailoring residual stress profile of selective laser melted parts by laser shock peening. Addit Manuf 16:90–97

Kalentics N, Boillat E, Peyre P, Gorny C, Kenel C, Leinenbach C, Jhabvala J, Logé RE (2017) 3D laser shock peening—a new method for the 3D control of residual stresses in Selective Laser Melting. Mater Des 130:350–356

Kalentics N, Burn A, Cloots M, Logé RE (2019) 3D laser shock peening as a way to improve geometrical accuracy in selective laser melting. Int J Adv Manuf Tech 101(5–8):1247–1254

Kalentics N, Sohrabi N, Tabasi HG, Griffiths S, Jhabvala J, Leinenbach C, Burn A, Logé RE (2019) Healing cracks in selective laser melting by 3D laser shock peening. Addit Manuf 30:100881

Kalentics N, Seijas M, Griffiths S, Leinenbach C, Logé RE (2020) 3D laser shock peening—a new method for improving fatigue properties of selective laser melted parts. Addit Manuf 33:101112

Ueda Y, Fukuda K, Nakacho K, Endo S (1975) A new measuring method of residual stresses with the aid of finite element method and reliability of estimated values. J Soc Nav Archit Jpn 138:499–507

Ueda Y, Kim YC, Yuan MG (1989) A predicting method of welding residual stress using source of residual stress (report I): characteristics of inherent strain (source of residual stress)(mechanics, strength & structural design). Trans JWRI 18(1):135–141

Chen Q, Liang X, Hayduke D, Liu JK, Cheng L, Oskin J, Whitmore R, To AC (2019) An inherent strain based multiscale modeling framework for simulating part-scale residual deformation for direct metal laser sintering. Addit Manuf 28:406–418

Liang X, Chen Q, Cheng L, Hayduke D, To AC (2019) Modified inherent strain method for efficient prediction of residual deformation in direct metal laser sintered components. Comput Mech 64(6):1719–1733

Zhang YK, Yang QT, Yang ZF, Zhang Z, Yu QY (2020) Method for rapidly forming a part using combination of arc deposition and laser shock forging and device implementing same. US10682716B2

Cai SP, Zhang YK (2022) An iterative approach combined with multi-dimensional fitting of limited measured stress points to reconstruct residual stress field generated by laser shock peening. Surf Coat Technol 436:128237

Prabhakaran S, Kalainathan S (2016) Warm laser shock peening without coating induced phase transformations and pinning effect on fatigue life of low-alloy steel. Mater Des 107:98–107

Sano Y, Masaki K, Gushi T, Sano T (2012) Improvement in fatigue performance of friction stir welded A6061–T6 aluminum alloy by laser peening without coating. Mater Des 36:809–814

Lv JM, Luo KY, Lu HF, Wang Z, Liu JJ, Lu JZ (2022) Achieving high strength and ductility in selective laser melting Ti-6Al-4V alloy by laser shock peening. J Alloy Compd 899:163335

Goldak J, Akhlaghi M (2006) Computational welding mechanics. Springer, New York

Lu X, Cervera M, Chiumenti M, Lin X (2021) Residual stresses control in additive manufacturing. J Manuf Mater Process 5:138

Luo C, Qiu JH, Yan YG, Yang JH, Uher C, Tang XF (2018) Finite element analysis of temperature and stress fields during the selective laser melting process of thermoelectric SnTe. J Mater Process Tech 261:74–85

Zhou XM, Zhang HO, Wang GL, Bai XW, Fu YH, Zhao JY (2016) Simulation of microstructure evolution during hybrid deposition and micro-rolling process. J Mater Sci 51(14):6735–6749

Smith MC, Bouchard PJ, Turski M, Edwards L, Dennis RJ (2012) Accurate prediction of residual stress in stainless steel welds. Comp Mater Sci 54:312–328

Ahn J, He E, Chen L, Wimpory RC, Dear JP, Davies CM (2017) Prediction and measurement of residual stresses and distortions in fibre laser welded Ti-6Al-4V considering phase transformation. Mater Des 115:441–457

Lorentzen L, Hutchings MT, Withers PJ, Holden TM (2005) Introduction to Characterizing Residual Stress by Neurtron Diffraction. CRC Press, Florida, pp 1–24

Funding

The presented investigations have been supported by the National Natural Science Foundation of China (No. 51775117) and Research and Demonstration of the Key Technologies for the Next-Generation Deep-Water Offshore Ultra-Large Wind Turbine Installation Platforms (No. 502200029). All the supports above are greatly acknowledged.

Author information

Authors and Affiliations

Contributions

Yongkang Zhang: conceptualization; participation in the whole work; funding acquisition; and supervision; Shupeng Cai: participation in the whole work; writing of the article; data analysis and figure drawing; and revision of the manuscript; Zhifan Yang: data curation; Ming Qiu: development of equipment; Zhengang Wang: development of equipment; Pingping Wu: development of equipment; Chi Xue: development of equipment; Xiaojian Huo: development of equipment. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Cai, S., Yang, Z. et al. Laser shock forging—a novel in situ method designed towards controlling residual stresses in laser metal deposition. Int J Adv Manuf Technol 125, 2289–2304 (2023). https://doi.org/10.1007/s00170-023-10874-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-10874-8