Abstract

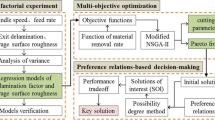

Carbon fiber–reinforced polymer (CFRP) has the characteristics of high brittleness and high hardness, which easily causes delamination damage and burr damage, resulting in low hole-making efficiency, and the application of cutting fluid in the process will lead to the decrease of mechanical properties of the material. In order to improve the surface quality and processing efficiency of CFRP, an ultrasonic-assisted dry helical milling technology is proposed. Taking tool rotation speed, feed rate, pitch, and ultrasonic amplitude as optimization variables and taking minimum delamination damage, burr damage, and maximum material removal rate as objective functions, multi-objective optimization models are established through experiments and genetic algorithm, and Pareto optimal solution sets are obtained. The results show that the influence weights are in the order of pitch, tool rotation speed, ultrasonic amplitude, and feed rate for the analysis of variance of delamination damage, accounting for 38.7%, 24.9%, 20.9%, and 15.5%, respectively. The maximum weight of pitch is 29.7%, and the minimum weight of ultrasonic amplitude is 18.1%, in the analysis of variance of burr damage. Finally, multi-objective optimization models are verified by experiments, and it is concluded that the established optimization models can provide multiple parameter optimization schemes for different engineering applications with high accuracy.

Similar content being viewed by others

References

Geng DX, Liu YH, Shao ZY, Lu ZH, Cai J et al (2019) Delamination formation, evaluation and suppression during drilling of composite laminates: a review. Compos Struct 216:168–186. https://doi.org/10.1016/j.compstruct.2019.02.099

Jiao F, Li YX, Niu Y, Zhang ZQ, Bie WB (2022) A review on the drilling of CFRP/Ti stacks: machining characteristics, damage mechanisms and suppression strategy at stack interface. Compos Struct 305:1–51. https://doi.org/10.1016/j.compstruct.2022.116489

Wang D, Jiao F, Zhang SJ, Liao YX (2020) Dynamic impact effect analysis for longitudinal ultrasonic vibration drilling of CFRP/titanium alloy laminated plate. J Vib Shock 39(17):47–56. https://doi.org/10.13465/j.cnki.jvs.2020.17.007

Wang D, Jiao F, Mao XS (2020) Mechanics of thrust force on chisel edge in carbon fiber reinforced polymer (CFRP) drilling based on bending failure theory. Int J Mech Sci 169:1–13. https://doi.org/10.1016/j.ijmecsci.2019.105336

Zhang SJ, Jiao F, Li YX, Wang D, Niu Y (2020) Experimental study on high and low frequency compound vibration drilling of carbon fiber reinforced plastic/titanium alloy laminated structure. Machine Design Res 36(06):120–124+129. https://doi.org/10.13952/j.cnki.jofmdr.2020.0248

Feng ZB, Jiao F (2022) Study on exit damage characteristics of ultrasonic vibration assisted drilling of CFRP. Adv Mech Eng 14(5):1–11. https://doi.org/10.1177/16878132221100653

Karataş MA, Gökkaya H (2018) A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def Technol 14(4):318–326. https://doi.org/10.1016/j.dt.2018.02.001

Gao T, Li CH, Wang YQ, Liu XS, An QL, Li HN, et al (2022) Carbon fiber reinforced polymer in drilling: from damage mechanisms to suppression. Compos Struct 286:1–26. https://doi.org/10.1016/j.compstruct.2022.115232

Liu DF, Tang YJ, Cong WL (2012) A review of mechanical drilling for composite laminates. Compos Struct 94(4):1265–1279. https://doi.org/10.1016/j.compstruct.2011.11.024

Che D, Saxena I, Han P, Guo P, Ehmann KF (2014) Machining of carbon fiber reinforced plastics/polymers: a literature review. J Manuf Sci Eng 136(3):034001–034022. https://doi.org/10.1115/1.4026526

Li CX (2019) Application of carbon fiber and its composite materials in automobile field. Adv Mater Ind (1):5–7. https://doi.org/10.19599/j.issn.1008-892x.2019.01.003

Che SJ, Zhang MR (2022) Review of the application of composite materials in rail transit. Fiber Composites 39(2):100–104

Li CL, Yang C, Ni AQ, Wang JH, Song QX (2022) Application and development of composite materials on large-scale wind turbine blade. Acta Materiae Compositae Sinica 40:1–11. https://doi.org/10.13801/j.cnki.fhclxb.20220715.001

Plushchik OA, Aniskevich AN (2000) Effects of temperature and moisture on the mechanical properties of polyester resin in tension. Mech Compos Mater 36(3):233–240. https://doi.org/10.1007/BF02681875

Gao T, Li CH, Jia DZ, Zhang YB, Yang M, Wang XM et al (2020) Surface morphology assessment of CFRP transverse grinding using CNT nanofluid minimum quantity lubrication. J Clean Prod 277:1–14. https://doi.org/10.1016/j.jclepro.2020.123328

Gao T, Li CH, Yang M, Zhang YB, Jia DZ, Ding WF et al (2021) Mechanics analysis and predictive force models for the single-diamond grain grinding of carbon fiber reinforced polymers using CNT nano-lubricant. J Mater Process Technol 290:1–16. https://doi.org/10.1016/j.jmatprotec.2020.116976

Gao T, Zhang YB, Li CH, Wang YQ, An QL, Liu B et al (2021) Grindability of carbon fiber reinforced polymer using CNT biological lubricant. Springer Sci Bus Media LLC 11(1):22535. https://doi.org/10.1038/s41598-021-02071-y

Gao T, Zhang YB, Li CH, Wang YQ, Chen Y, An QL et al (2022) Fiber-reinforced composites in milling and grinding: machining bottlenecks and advanced strategies. Front Mech Eng 17(2):1–35. https://doi.org/10.1007/s11465-022-0680-8

Xu WH, Li CH, Zhang YB, Ali HM, Sharma S, Li RZ et al (2022) Electrostatic atomization minimum quantity lubrication machining: from mechanism to application. Int J Extreme Manuf 4(4):1–43. https://doi.org/10.1088/2631-7990/ac9652

Deng Y (2021) Dry cutting and its applications. Mech Eng Autom 5:220–221

Jia DZ, Zhang NQ, Liu B, Zhou ZM et al (2021) Particle size distribution characteristics of electrostatic minimum quantity lubrication and grinding surface quality evaluation. Diamond Abrasives Eng 41(3):89–95. https://doi.org/10.13394/j.cnki.jgszz.2021.3.0013

Wu Z, Yang Y, Su C, Cai X, Luo C (2017) Development and prospect of cooling technology for dry cutting tools. Int J Adv Manuf Technol 88(5–8):1567–1577. https://doi.org/10.1007/s00170-016-8842-7

Diniz AE, de Oliveira AJ (2004) Optimizing the use of dry cutting in rough turning steel operations. Int J Mach Tools Manuf 44(10):1061–1067. https://doi.org/10.1016/j.ijmachtools.2004.03.001

Li CH (2022) Research progress and prospect of clean cutting and enabling technology. Metal Working (Metal Cutting) 3:6–8

Li YX, Jiao F, Zhang SJ, Zhang S et al (2021) Experiment on high and low frequency compound vibration-assisted drilling of CFRP/titanium alloy laminated structure. Acta Aeronautica et Astronautica Sinica 42(10):344–357. https://doi.org/10.7527/S1000-6893.2020.24802

Zhang S, Jiao F, Wang X, Niu Y (2021) Modeling of cutting forces in helical milling of unidirectional CFRP considering carbon fiber fracture. J Manuf Process 68:1495–1508. https://doi.org/10.1016/j.jmapro.2021.06.058

Pereira RBD, Brandao LC, de Paiva AP, Ferreira JR, Davim JP (2017) A review of helical milling process. Int J Mach Tools Manuf 120:27–48. https://doi.org/10.1016/j.ijmachtools.2017.05.002

Wang HY, Qin XD, Li H, Tan YQ (2016) A comparative study on helical milling of CFRP/Ti stacks and its individual layers. Int J Adv Manuf Technol 86(5–8):1973–1983. https://doi.org/10.1007/s00170-015-8296-3

Li X (2015) Pressure-force optimization in the process of robotic automatic orbital drilling. Zhejiang University

Yang GL (2021) Technology and equipment of helical milling for aerospace components assembly. Dalian University of Technology

Yang ZC, Zhu LD, Zhang GX, Ni CB, Lin B (2020) Review of ultrasonic vibration-assisted machining in advanced materials. Int J Mach Tools Manuf 156:1–34. https://doi.org/10.1016/j.ijmachtools.2020.103594

Chen G, Zou YH, Qin XD, Liu J, Feng Q, Ren CZ (2020) Geometrical texture and surface integrity in helical milling and ultrasonic vibration helical milling of Ti-6Al-4V alloy. J Mater Process Technol 278:1–13. https://doi.org/10.1016/j.jmatprotec.2019.116494

Tang J, Li WX, Zhao B (2019) Design and experiment of longitudinal-torsional composite ultrasonic helical milling hole system. Mach Tool Hydraul 47(13):22–28

Gao H, Sun C, Ran C, Zhang X, Li LL (2015) Drilling experiment of laminated composites by ultrasonic vibration assisted helical milling method. Acta Armamentarh 36(12):2342–2349

Liu J, Chen G, Ren CZ (2020) Effects of axial and longitudinal-torsional vibration on fiber removal in ultrasonic vibration helical milling of CFRP composites. J Manuf Process 58:868–883. https://doi.org/10.1016/j.jmapro.2020.08.071

Fang CP, Zhao JZ, Ye ZM, Guo AR, Ling L (2020) Research progress on helical milling of carbon fiber reinforced composites. Compos Sci Eng 11:123–128

Dong HY, Chen GL, Zhou L, He FT, Liu ST (2017) Processing research on orbital drilling of CFRP/Ti-6Al-4V stacks. Acta Materiae Compositae Sinica 34(3):540–549. https://doi.org/10.13801/j.cnki.fhclxb.20160616.001

Niu Y, Jiao F, Zhao B, Wang XB (2020) Multi-objective parameter optimization for ultrasonic milling of titanium alloy in longitudinal and torsional directions based on NSGA-II. J Vib Shock 39(21):241–249. https://doi.org/10.13465/j.cnki.jvs.2020.21.032

Wang HY, Tao KX, Wang JY, Jin T, Wu DX (2020) Optimization of cutting parameters in ball helical milling process based on grey system theory. Chinese J Construct Mach 18(04):348–353. https://doi.org/10.15999/j.cnki.311926.2020.04.013

Gao YF, Pu JW, Fang XE (2019) Multi-objective optimization of helical milling process for CFRP/titanium alloy stacks based on Taguchi grey relational analysis. Aeronaut Manuf Technol 62(14):90–95+102. https://doi.org/10.16080/j.issn1671-833x.2019.14.090

Liu SN, Xia WQ, Wang N, Song Y, Luo B, Zhang KF (2020) Multi-objective drilling parameters optimization method for CFRP/Ti stacks. J Mech Eng 56(07):193–203

Wang HY, Qin XD, Wu DX, Song AJ et al (2018) Optimization of cutting parameters in helical milling of carbon fiber reinforced polymer. Trans Tianjin Univ 24(1):91–100. https://doi.org/10.1007/s12209-017-0079-5

Pereira RBD, Silva LAd, Lauro H et al (2019) Multi-objective robust design of helical milling hole quality on AISI H13 hardened steel by normalized normal constraint coupled with robust parameter design. Appl Soft Comput J 75:652–685. https://doi.org/10.1016/j.asoc.2018.11.040

Alvim AC, Ferreira JR, Pereira RBD (2022) The enhanced normalized normal constraint approach to multi-objective robust optimization in helical milling process of AISI H13 hardened with crossed array. Int J Adv Manuf Technol 119(3–4):2763–2784. https://doi.org/10.1007/s00170-021-08259-w

Rodrigues VFS, Ferreira JR, de Paiva AP et al (2019) Robust modeling and optimization of borehole enlarging by helical milling of aluminum alloy Al7075. Int J Adv Manuf Technol 100(9–12):2583–2599. https://doi.org/10.1007/s00170-018-2832-x

Liu W, Wang TY (2011) Optimization of cutting parameters based on Pareto genetic algorithm. Trans Chinese Soc Agric Mach 42(2):220–224+234

Kuo CL, Li ZH, Wang CY (2017) Multi-objective optimisation in vibration-assisted drilling of CFRP/Al stacks. Compos Struct 173:196–209. https://doi.org/10.1016/j.compstruct.2017.04.026

Lu C (2012) The optimization research on helical milling of CFRP/Ti-6Al-4V stacks. Tianjin University

Zhang YD (1995) Ultrasonic machining and its application. National Defense Industry Press

Faraz A, Biermann D, Weinert K (2009) Cutting edge rounding: an innovative tool wear criterion in drilling CFRP composite laminates. Int J Mach Tools Manuf 49(15):1185–1196. https://doi.org/10.1016/j.ijmachtools.2009.08.002

Funding

This work were supported by the National Natural Science Foundation of China (Grant No. 51675164) and the Fundamental Research Funds for the Universities of Henan Province (Grant No. NSFRF200102).

Author information

Authors and Affiliations

Contributions

Xue Wang: conceptualization, methodology, software, and writing of original draft. Feng Jiao: conceptualization, supervision, methodology, funding acquisition, and writing including review and editing. Shun Zhang: investigation and software. Yuanxiao Li: investigation and software. Jinglin Tong: investigation and resources. Ying Niu: software and supervision.

Corresponding author

Ethics declarations

Ethical approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Jiao, F., Zhang, S. et al. Optimization model for ultrasonic-assisted dry helical milling of CFRP based on genetic algorithm. Int J Adv Manuf Technol 131, 2133–2143 (2024). https://doi.org/10.1007/s00170-022-10766-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10766-3