Abstract

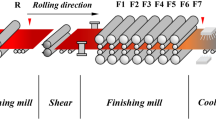

The prediction accuracy of the rolling force is crucial for the strip hot rolling process, which will significantly affect the dimensional control accuracy of the strip product. The rolling force prediction models used in actual strip hot rolling production before are mainly analytical models and simple neural network models, but with the improvement of product quality, these models can no longer meet the requirements of high-end product production. A new online model based on the gradient boosting decision tree (GBDT) method is proposed to improve the accuracy of the online prediction of rolling force, in which the random forest method based on feature importance is adopted to select feature parameters. A model self-training function was developed in the control system to ensure the accuracy of the model used online. By comparing various machine learning methods, the results show that the rolling force prediction model proposed by the GBDT is better than that based on other regression methods. The established model has been successfully applied to predict the rolling force for the finishing rolling in a 2250 mm strip hot rolling production line. Compared with the traditional model, the rolling force prediction accuracy and thickness control accuracy are significantly improved.

Similar content being viewed by others

Data availability

The authors confirm that the data and material supporting the findings of this work are available within the article.

Code availability

The authors confirm that the code supporting the findings of this work is available within the article.

References

Wang ZH, Zhang DH, Gong DY, Peng W (2019) A new data-driven roll force and roll torque model based on FEM and hybrid PSO-ELM for hot strip rolling. ISIJ Int 59(9):1604–1613. https://doi.org/10.2355/isijinternational.isijint-2018-846

Bagheripoor M, Bisadi H (2013) Application of artificial neural networks for the prediction of roll force and roll torque in hot strip rolling process. Appl Math Model 37(7):4593–4607. https://doi.org/10.1016/j.apm.2012.09.070

Nagra AA, Han F, Ling QH, Mehta S (2019) An improved hybrid method combining gravitational search algorithm with dynamic multi swarm particle swarm optimization. IEEE Access 7:50388–50399. https://doi.org/10.1109/ACCESS.2019.2903137

Avalos O (2020) GSA for machine learning problems: a comprehensive overview. Appl Math Model 92:261–280. https://doi.org/10.1016/j.apm.2020.11.013

Zhang R, Song SJ, Wu C (2020) Robust scheduling of hot rolling production by local search enhanced ant colony optimization algorithm. IEEE Trans Industr Inf 16:2809–2819. https://doi.org/10.1109/TII.2019.2944247

Deng JF, Sun J, Peng W, Hu YH, Zhang DH (2019) Application of neural networks for predicting hot-rolled strip crown. Appl Soft Comput 78:119–131. https://doi.org/10.1016/j.asoc.2019.02.030

Liu X, Athanasiou CE, Padture NP, Sheldon BW, Gao HJ (2020) A machine learning approach to fracture mechanics problems. Acta Mater 190:105–112. https://doi.org/10.1016/j.actamat.2020.03.016

Alaei H, Salimi M, Nourani A (2016) Online prediction of work rolls thermal expansion in a hot rolling process by a neural network. Int J Adv. Manuf. Technol. 85:1769–1777. https://doi.org/10.1007/s00170-015-8073-3

Liu CJ, Ding WF, Li Z, Yang CY (2016) Prediction of high-speed grinding temperature of titanium matrix composites using BP neural network based on PSO algorithm. Int. J. Adv. Manuf. Technol. 89:1–9. https://doi.org/10.1007/s00170-016-9267-z

Shardt Yuri AW, Mehrkanoon S, Zhang K, Yang X, Suykens J, Ding SX, Peng KX (2017) Modelling the strip thickness in hot steel rolling mills using least-squares support vector machines. The Canadian Journal of Chemical Engineering 96:171–178. https://doi.org/10.1002/cjce.22956

Song LB, Xu D, Wang XC, Yang Q, Ji YF (2022) Application of machine learning to predict and diagnose for hot-rolled strip crown. Int J Adv Manuf Technol 120:881–890. https://doi.org/10.1007/s00170-022-08825-w

Shen CG, Wang CC, Wei XL, Li Y, Zwaag S, Xu W (2019) Physical metallurgy-guided machine learning and artificial intelligent design of ultrahigh-strength stainless steel. Acta Mater 179:201–214. https://doi.org/10.1016/j.actamat.2019.08.033

Wang ZH, Liu YM, Gong DY, Zhang DH (2018) A new predictive model for strip crown in hot rolling by using the hybrid AMPSO-SVR-Based approach. Steel research int. 89(7). https://doi.org/10.1002/srin.20180 0003

Zhang SH, Deng L, Tian WH, Che LZ, Li Y (2022) Deduction of a quadratic velocity field and its application to rolling force of extra-thick plate. Comput Math Appl 109:58–73. https://doi.org/10.1016/j.camwa.2022.01.024

Zhang SH, Deng L, Che LZ (2022) An integrated model of rolling force for extra-thick plate by combining theoretical model and neural network model. J Manuf Process 75:100–109. https://doi.org/10.1016/j.jmapro.2021.12.063

Qureshi AS, Khan A, Zameer A, Usman A (2017) Wind power prediction using deep neural network based meta regression and transfer learning. Appl Soft Comput 58:742–755. https://doi.org/10.1016/j.asoc.2017.05.031

Wang Y, Wang J, Yin C, Zhao Q (2020) Multi-objective optimization of rolling schedule for five-stand tandem cold mill. IEEE Access 8:80417–80426. https://doi.org/10.1109/access.2020.2990904

Hwang R, Jo H, Kim KS, Hwang HJ (2020) Hybrid model of mathematical and neural network formulations for rolling force and temperature prediction in hot rolling processes. IEEE Access 8:153123–153133. https://doi.org/10.1109/ACCESS.2020.3016725

Tuia D, Verrelst J, Alonso L, Perez-Cruz F, Camps-Valls G (2011) Multioutput support vector regression for remote sensing biophysical parameter estimation. IEEE Geosci Remote Sens Lett 8:804–808. https://doi.org/10.1109/LGRS.2011.2109934

Nguyen HM, Kalra G, Jun T, Kim D (2020) Chaotic time series prediction using a novel echo state network model with input reconstruction, Bayesian ridge regression and independent component analysis. Int J. Pattern Recogn 34(06)2051008. https://doi.org/10.1142/S0218001420510088

Murasawa K, Ueno K, Kusuda Y, Takamura M, Hama T, Hakoyama T, Suzuki S (2022) Prediction of the stress decreasing behavior in the early stage of stress relaxation in steel sheet. ISIJ Int 62(5):1004–1012. https://doi.org/10.2355/isijinternational.ISIJINT-2021-423

Lu X, Sun J, Song ZX, Li GT, Wang ZH, Hu JY, Wang QL, Zhang DH (2020) Prediction and analysis of cold rolling mill vibration based on a data-driven method. Appl Soft Comput 96:106706. https://doi.org/10.1016/j.asoc.2020.106706

Sims RB (1954) The calculation of roll force and torque in hot rolling mills. Proceedings of the Institution of Mechanical Engineers 168(1):191–200. https://doi.org/10.1243/PIME_PROC_1954_168_023_02

Breiman L (2001) Random forests. Mach Learn 45(1):5–32. https://doi.org/10.1023/A:1010933404324

De’ath G, Fabricius KE, (2000) Classification and regression trees: a powerful yet simple technique for ecological data analysis. Ecology 81(11):178–3192. https://doi.org/10.1890/0012-9658(2000)081[3178:CARTAP]2.0.CO;2

Scott CD, Willett M, Nowak RD (2003) Classification or regression trees. IEEE Acoustics Speech and Signal Processing 4(6):153–156. https://doi.org/10.1109/ICASSP.2003.1201641

Deng SK, Wang CG, Wang MY (2019) A gradient boosting decision tree approach for insider trading identification: an empirical model evaluation of China stock market. Appl Soft Comput 83:105652–105677. https://doi.org/10.1016/j.asoc.2019.105652

Friedman JH (2001) Greedy function approximation: a gradient boosting machine. Ann Stat 29(5):1189–1232. https://doi.org/10.2307/2699986

Funding

This work was financially supported by the China Postdoctoral Science Foundation (Grant No. 2021M690352) and the National Natural Science Foundation of China (Grant No. 51975043).

Author information

Authors and Affiliations

Contributions

Qiuna Wang: writing—original draft. Lebao Song: software and methodology. Jianwei Zhao: conceptualization and data validation. Haiyu Wang: software and visualization. Lijie Dong: resources and investigation. Xiaochen Wang: writing—review and editing. Quan Yang: supervision.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent for publication

This work is approved by all authors for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Q., Song, L., Zhao, J. et al. Application of the gradient boosting decision tree in the online prediction of rolling force in hot rolling. Int J Adv Manuf Technol 125, 387–397 (2023). https://doi.org/10.1007/s00170-022-10716-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10716-z