Abstract

Binder jetting (BJ) is an additive manufacturing technology that realizes mineral or metallic parts without support material and avoiding critical issues due to thermal phenomena. Because of these benefits, this technology is suitable for rapid tooling applications, as well as for casting process to produce complex moulds made for instance in plaster and organic compound as binder. Regarding the latter application, it is worth noting that chemical reactions can occur when the mould is in contact with molten metal, leading to the formation of gas and therefore porosity in the cast part. To limit this phenomenon, a burnout cycle is usually required before pouring the molten metal.

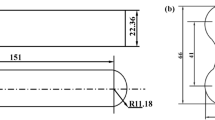

In this research, the burnout temperature and time were investigated, as well as the pre-heating mould temperature before metal pouring in case of simple and complex part geometries. Three different levels of each studied parameters were tested, and the results were analysed in terms of casting defects. Results highlight that a burnout treatment performed at 250 °C for 6 h guarantees the best compromise in terms of casting soundness.

Similar content being viewed by others

Change history

31 January 2023

A Correction to this paper has been published: https://doi.org/10.1007/s00170-023-11011-1

References

Dilberoglu UM, Gharehpapagh B, Yaman U, Dolen M (2017) The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manufacturing 11:545–554. https://doi.org/10.1016/j.promfg.2017.07.148

Gibson I, Rosen DW, Stucker B (2010) Additive manufacturing technologies: Rapid prototyping to direct digital manufacturing Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing, pp. 1–459. https://doi.org/10.1007/978-1-4419-1120-9

Gaub H (2016) Customization of mass-produced parts by combining injection molding and additive manufacturing with Industry 4.0 technologies. Reinf Plast 60(6):401–404. https://doi.org/10.1016/j.repl.2015.09.004

Cheah CM, Chua CK, Lee CW, Feng C, Totong K (2005) Rapid prototyping and tooling techniques: a review of applications for rapid investment casting. Int J Adv Manuf Technol 25(3–4):308–320. https://doi.org/10.1007/s00170-003-1840-6

Thomas P.A, Aahlada P.K, Kiran N.S, Ivvala J (2018) A review on transition in the manufacturing of mechanical components from conventional techniques to rapid casting using rapid prototyping materials today: proceedings, 5 (5), pp. 11990–12002. https://doi.org/10.1016/j.matpr.2018.02.173

Wang H, Fu Y, Su M, Hao H (2019) Effect of structure design on compressive properties and energy absorption behavior of ordered porous aluminum prepared by rapid casting. Mater Des 167:107631. https://doi.org/10.1016/j.matdes.2019.107631

Casalino G, De Filippis LAC, Ludovico A (2005) A technical note on the mechanical and physical characterization of selective laser sintered sand for rapid casting. J Mater Process Technol 166(1):1–8. https://doi.org/10.1016/j.jmatprotec.2004.07.102

Wang J, Sama SR, Lynch PC, Manogharan G (2019) Design and topology optimization of 3D-printed wax patterns for rapid investment casting 34, pp. 683–694. https://doi.org/10.1016/j.promfg.2019.06.224

Csáky V, Neto RJ, Duarte TP, Lino Alves J, Couto M, Machado M (2014) A framework for custom design and fabrication of cranio-maxillofacial prostheses using investment casting Engineering Optimization IV - Proceedings of the 4th International Conference on Engineering Optimization, ENGOPT 941–946. https://doi.org/10.1201/b17488-170

Le Néel TA, Mognol P, Hascoët J-Y (2018) A review on additive manufacturing of sand molds by binder jetting and selective laser sintering. Rapid Prototyping J 24(8):1325–1336. https://doi.org/10.1108/RPJ-10-2016-0161

Snelling DA, Williams CB, Druschitz AP (2019) Mechanical and material properties of castings produced via 3D printed molds. Addit Manuf 27:199–207. https://doi.org/10.1016/j.addma.2019.03.004

Chhabra M, Singh R (2011) Rapid casting solutions: a review. Rapid Prototyping J 17(5):328–350. https://doi.org/10.1108/13552541111156469

Sivarupan T, Balasubramani N, Saxena P, Nagarajan D, El Mansori M, Salonitis K, Jolly M, Dargusch MS (2021) A review on the progress and challenges of binder jet 3D printing of sand moulds for advanced casting. Additive Manuf 40:101889. https://doi.org/10.1016/j.addma.2021.101889

DebRoy T, Wei HL, Zuback JS, Mukherjee T, Elmer JW, Milewski JO, Beese AM, Wilson-Heid A, De A, Zhang W (2018) Additive manufacturing of metallic components – Process, structure and properties. Prog Mater Sci 92:112–224. https://doi.org/10.1016/j.pmatsci.2017.10.001

Giorleo L, Bonaventi M (2011) Casting of complex structures in aluminum using gypsum molds produced via binder jetting. Rapid Prototyping J 27(11):13–23. https://doi.org/10.1108/RPJ-03-2020-0048

Castro-Sastre MA, Fernández-Abia AI, Rodríguez-González P, Martínez-Pellitero S, Barreiro J (2018) Characterization of materials used in 3D-printing technology with different analysis techniques. Ann DAAAM Proceed Int DAAAM Symposium 29(1):947–954. https://doi.org/10.2507/29th.daaam.proceedings.136

Castro-Sastre MÁ, Fernández-Abia AI, Piep J, Rodríguez-González P, Barreiro J (2020) Towards functional parts by binder jetting calcium-sulphate with thermal treatment post-processing. Materials 13(17):3818. https://doi.org/10.3390/ma13173818

Singamneni S, McKenna N, Diegel O, Singh D, Neitzert T, St. George J, Choudhury AR, Yarlagadda P (2009) Rapid casting: a critical analysis of mould and casting characteristics. Australian J Mechanical Eng 7(1):33–44. https://doi.org/10.1080/14484846.2009.11464576

Bassoli E, Atzeni E (2009) Direct metal rapid casting: Mechanical optimization and tolerance calculation. Rapid Prototyping J 15(4):238–243. https://doi.org/10.1108/13552540910979758

Rodríguez-González P, Valero PER, Fernández-Abia AI, Castro-Sastre MÁ, García JB (2020) Feasibility of calcium sulfate moulds made by inkjet 3D printing for rapid casting of aluminium alloys. Metals, 10 (6) 802, 1–17. https://doi.org/10.3390/met10060802

Rodríguez-González P, Fernández-Abia AI, Castro-Sastre MA, Barreiro J (2020) Heat treatments for improved quality binder jetted molds for casting aluminum alloys. Additive Manuf 36:101524. https://doi.org/10.1016/j.addma.2020.101524

Campbell J (1993) Invisible macrodefects in castings. J De Physique 3(7 pt 2):861–872. https://doi.org/10.1051/jp4:19937135

Song KM, Mitchell J, Gladden LF (2009) Magnetic resonance studies of hydration kinetics and microstructural evolution in plaster pastes. J Mater Sci 44(18):5004–5012. https://doi.org/10.1007/s10853-009-3765-4

Brown JR (1999) Chapter 7 - Running, gating and feeding aluminium castings, Editor(s): John R. Brown, Foseco Non-Ferrous Foundryman's Handbook, Butterworth-Heinemann, 1999, Pages 89-II, ISBN 9780750642866. https://doi.org/10.1016/B978-075064286-6/50008-5.

3D Systems (2019) Safety Data Sheet: VisiJet PXL Colors, U.S.A

3D Systems (2019) Safety Data Sheet: VisiJet PXL Core, U.S.A

Carlson KD, Beckermann C (2009) Prediction of shrinkage pore volume fraction using a dimensionless Niyama criterion. Metallurgical Mater Trans A: Phys Metallurgy Mater Sci 40(1):163–175. https://doi.org/10.1007/s11661-008-9715-y

Clifton JR (1972) Thermal analysis of Calcium sulphate dihydrate and supposed alpha and beta forms of Calcium sulfate hemihydrate from 25 to 500CC. J Res Natl Bur Stand A Phys Chem 76(1):41–49. https://doi.org/10.6028/jres.076A.005

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Luca Giorleo, Ertuğrul Varlik, Lorenzo Montesano, and Annalisa Pola. The first draft of the manuscript was written by Luca Giorleo and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Author given and last names were interchanged.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Giorleo, L., Varlik, E., Montesano, L. et al. Burnout treatment on plaster mould produced with binder jetting technology: effect of process parameters and geometrical complexity. Int J Adv Manuf Technol 124, 2769–2780 (2023). https://doi.org/10.1007/s00170-022-10700-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10700-7