Abstract

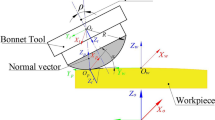

The industrial robot bonnet polishing platform can not only meet the requirements of high efficiency and precision of optical polishing, but also reduce the system cost. It is a promising polishing equipment solution. The most practical method to improve BP material removal efficiency is to increase the contact depth. It is generally believed that the profile of the tool influence function (TIF) of BP is Gaussian-like distribution traditionally, but it is found that it actually changes into M-shape obviously with large contact depth. However, the existing reports on the TIF of bonnet polishing are mostly based on the Gaussian like TIF model which cannot accurately describe the M-shaped TIF. Therefore, according to the material characteristics of inflatable rubber bonnet, this paper establishes a new model to explain the changes of pressure distribution caused by large contact depth. Furthermore, a bonnet polishing approach based on dual-mode contact depth TIF is proposed in order to improve the removal efficiency in rough polishing stage and increase the convergence accuracy in fine polishing stage.

Similar content being viewed by others

Abbreviations

- TIF:

-

Tool influence function

- BP:

-

Bonnet polishing

- \(K\) :

-

Constant in Preston equation \(\Delta Z=K\bullet P(x,y)\bullet V(x,y)\bullet \Delta t\)

- \(P\) :

-

Contacting pressure distribution in the contact area

- \(V\) :

-

Relative velocity distribution in the contact area

- \(\Delta Z\) :

-

Removed material amount

- \(\Delta t\) :

-

Dwell time

- \(R\) :

-

Radius of the bonnet

- \(d\) :

-

Contact depth

- \(n\) :

-

Rotation speed

- \({\omega }_{H}\) :

-

Rotation angle speed

- \(\rho\) :

-

Precession angle

- \({r}_{i}\) :

-

Radius of the contact area

- \({F}_{x}\), \({F}_{y}\), \({F}_{z}\) :

-

3-Dimension contacting polishing forces

- \(E\) :

-

Total strain of the bonnet

- \(e\) :

-

Virtual strain of the bonnet

- \(\varepsilon\) :

-

Actual strain of the bonnet

References

Jones RA (1986) Computer controlled optical surfacing with orbital tool motion. SPIE Proc 1333:12

Pan R, Bo Z, Chen D, Wang Z, Wei S (2018) Modification of tool influence function of bonnet polishing based on interfacial friction coefficient. Int J Mach Tools Manuf 124:43–52

Su X, Ji P, Jin Y, Li D, Wang B (2019) Simulation and experimental study on form-preserving capability of bonnet polishing for complex freeform surfaces. Precis Eng 60:54–62

Li H, Walker D, Yu G, Zhang W (2013) Modeling and validation of polishing tool influence functions for manufacturing segments for an extremely large telescope. Appl Opt 52(23):5781–5787

Walker DD, Brooks D, King A, Freeman R, Morton R, McCavanaG KSW (2003) The ‘Precessions’ tooling for polishing and figuring flat, spherical and aspheric surfaces. Opt Express 11(8):958–964

Walker DD, Freeman R, Morton R, McCavana G, Beaucamp A (2006) Use of the ‘Precessions’ TM process for prepolishing and correcting 2D & 21/2D form. Opt Express 14(24):11787–117957

Wang C, Wang Z, Yang X, Sun Z, Peng Y, Guo Y, Xu Q (2014) Modeling of the static tool influence function of bonnet polishing based on FEA. Int J Adv Manuf Technol 74(1–4):341–349

Shorter R, Smith JD, Coveney VA, Busfield JJC (2010) Axial compression of hollow elastic spheres. J Mech Mater Struct 5(5):693–705

Shiou F-J, Loc PH, Dang NH (2013) Surface finish of bulk metallic glass using sequential abrasive jet; polishing and annealing processes. Int J Adv Manuf Technol 66(9–12):1523–1533

Sarkar M, Jain VK, Sidpara A (2019) On the flexible abrasive tool for nanofinishing of complex surfaces. J Adv Manuf Syst 18:157–166

Cao Z-C, Cheung CF, Ho LT, Liu MY (2017) Theoretical and experimental investigation of surface generation in swing precess bonnet polishing of complex three-dimensional structured surfaces. Precis Eng 50:361–371

Tao J, Judong L, Jun P, Zhilong X, Zhihuang S (2018) Simulation and experimental study on the concave influence function in high efficiency bonnet polishing for large aperture optics. Int J Adv Manuf Technol 97:2431–2437

Beaucamp A, Namba Y (2013) Super-smooth finishing of diamond turned hard X-ray molding dies by combined fluid jet and bonnet polishing. CIRP Ann Manuf Technol 62:315–318

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception, design, and manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All authors approved the final manuscript and the submission to this journal.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Feng, J., Zhang, Y., Rao, M. et al. An adaptive bonnet polishing approach based on dual-mode contact depth TIF. Int J Adv Manuf Technol 125, 2183–2194 (2023). https://doi.org/10.1007/s00170-022-10694-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10694-2