Abstract

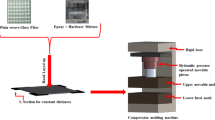

Fiber-reinforced composites have a wide range of industrial applications owing to their light weight, high modulus, and good specific strength. Trimming using a mechanical punching tool is the fastest way to post process fiber-reinforced composites. However, quantitative analyses of the defects and process parameters are required to analyze the damage mechanisms and achieve high-quality cut surfaces. In this study, we quantitively investigated the defects on the sheared edge of woven glass epoxy laminates subjected to mechanical punching and explored the correlations between these defects and key process parameters, including punch-die clearance, weave alignment angle, and laminate thickness. The results demonstrate the necessity of considering glass fiber burr length and the dimensions of the cracked area simultaneously to evaluate the quality of the sheared surface. This study provides qualitative data on the interfacial damage mechanisms that occur during mechanical punching, which will help to tailor the process parameters of mechanical punching for fiber-reinforced polymers to obtain smooth cut surfaces.

Similar content being viewed by others

Data availability

The datasets generated during the current study are available from the corresponding author on reasonable request.

Code availability

No applicable.

References

Sathishkumar TP, Satheeshkumar S, Naveen J (2014) Glass fiber-reinforced polymer composites – a review. J Reinf Plast Compos 33(13):1258–1275. https://doi.org/10.1177/0731684414530790

Rana S, Fangueiro R (2016) Advanced composites in aerospace engineering. In: Rana S, Fangueiro R (eds) Advanced composite materials for aerospace engineering. Woodhead Publishing, pp 1–15

Stewart R (2011) Rebounding automotive industry welcome news for FRP. Reinf Plast 55(1):38–44. https://doi.org/10.1016/S0034-3617(11)70036-4

Bank LC (2006) Composites for construction: structural design with FRP materials. John Wiley & Sons, Hoboken, NJ

Zagho MM, Hussein EA, Elzatahry AA (2018) Recent overviews in functional polymer composites for biomedical applications. Polymers 10(7):739. https://doi.org/10.3390/polym10070739

Wang DH, Ramulu M, Arola D (1995) Orthogonal cutting mechanisms of graphite/epoxy composite. part I: Unidirectional laminate. Int J Mach Tool Manuf 35(12):1623–1638. https://doi.org/10.1016/0890-6955(95)00014-O

Liu DF, Tang YJ, Cong WL (2012) A review of mechanical drilling for composite laminates. Compos Struct 94(4):1265–1279. https://doi.org/10.1016/j.compstruct.2011.11.024

Toubal L, Karama M, Lorrain B (2005) Stress concentration in a circular hole in composite plate. Compos Struct 68(1):31–36. https://doi.org/10.1016/j.compstruct.2004.02.016

Tsao CC, Hocheng H, Chen YC (2012) Delamination reduction in drilling composite materials by active backup force. CIRP Ann 61(1):91–94. https://doi.org/10.1016/j.cirp.2012.03.036

Armanios E, Bucinell R, Wilson D, Capello E, Tagliaferri V (2001) Drilling damage of GFRP and residual mechanical behavior—part II: Static and cyclic bearing loads. J Compos Technol Res 23(2):131–137. https://doi.org/10.1520/CTR10921J

Bhatnagar N, Ramakrishnan N, Naik NK, Komanduri R (1995) On the machining of fiber reinforced plastic (FRP) composite laminates. Int J Mach Tool Manuf 35(5):701–716. https://doi.org/10.1016/0890-6955(95)93039-9

Haddad M, Zitoune R, Bougherara H, Eyma F, Castanié B (2014) Study of trimming damages of CFRP structures in function of the machining processes and their impact on the mechanical behavior. Composites Part B: Engineering Engineering 57:136–143. https://doi.org/10.1016/j.compositesb.2013.09.051

Rao GVG, Mahajan P, Bhatnagar N (2007) Micro-mechanical modeling of machining of FRP composites – cutting force analysis. Compos Sci Technol 67(3–4):579–593. https://doi.org/10.1016/j.compscitech.2006.08.010

Davim JP, Reis P (2004) Multiple regression analysis (MRA) in modelling milling of glass fibre reinforced plastics (GFRP). Int J Manuf Technol Manag 6(1/2):185–197. https://doi.org/10.1504/IJMTM.2004.004514

Komanduri R (1997) Machining of fiber-reinforced composites. Mach Sci Technol 1(1):113–152. https://doi.org/10.1080/10940349708945641

Hocheng H, Tsao CC (2003) Comprehensive analysis of delamination in drilling of composite materials with various drill bits. J Mater Process Technol 140(1–3):335–339. https://doi.org/10.1016/S0924-0136(03)00749-0

Yokoi H, Nakagawa T, Kudo H (1983) Precision piercing and blanking of fiber reinforced plastics by vibro-punching. CIRP Ann 32(1):173–176. https://doi.org/10.1016/S0007-8506(07)63384-8

Nojima T (1998) A new punching method in intractable AFRP laminated composites by press working. JSME Int J Ser C 41(3):493–498. https://doi.org/10.1299/jsmec.41.493

Klocke F, Shirobokov A, Kerchnawe S, Wahl M, Mannens R, Feuerhack A, Mattfeld P (2017) Experimental investigation of the hole accuracy, delamination, and cutting force in piercing of carbon fiber reinforced plastics. Procedia CIRP 66:215–220. https://doi.org/10.1016/j.procir.2017.03.297

Lambiase F, Durante M (2017) Mechanical behavior of punched holes produced on thin glass fiber reinforced plastic laminates. Compos Struct 173:25–34. https://doi.org/10.1016/j.compstruct.2017.04.003

Berthelot J-M, Ling FF (1999) Composite materials: mechanical behavior and structural analysis. Springer, p 435

Barré S, Benzeggagh ML (1994) On the use of acoustic emission to investigate damage mechanisms in glass-fibre-reinforced polypropylene. Compos Sci Technol 52(3):369–376. https://doi.org/10.1016/0266-3538(94)90171-6s

Funding

This study has been conducted with the support of the Korea Institute of Industrial Technology as “Development of intelligent root technology with add-on modules (kitech EO-22–0005).” The sponsors had no involvement in the study design; in the collection, analysis, or interpretation of data; in the writing of the report; or in the decision to submit the article for publication.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All authors agree to transfer the copyright of this article to the publisher.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Choi, H.S., Jeon, Y.J., Choi, W.C. et al. Quantitative evaluation of the sheared edge of woven glass epoxy laminate after mechanical punching. Int J Adv Manuf Technol 124, 2313–2321 (2023). https://doi.org/10.1007/s00170-022-10621-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10621-5