Abstract

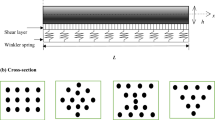

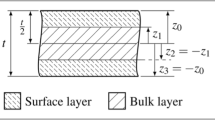

The study considers a method for forming stiffened monolithic panels by local deformation of the panel ribs. The local deformation is caused by bending moments along the rib towards each other. The goal of the study is to numerically model the forming process of the stiffened monolithic panel utilizing the designed local-impact tool and analyze its effects on the panel, obtaining which experimentally is challenging. The finite element method (FEM) modeling is performed in ANSYS and validated by the experimental forming of a panel made of an aluminum alloy analogous to Al 2024. Simulation results provide deformation, stress, and strain distributions along the panel in loaded and unloaded states for various study cases. Furthermore, the effects of finite panel length, width, and forming process parameters such as applied force couples and single versus successive deformation are numerically investigated and discussed. Performed modeling demonstrates the advantages of the forming with the designed tool in terms of low residual stresses and their distribution. Finally, the analysis suggests future modification of the tool, particularly the shape of its grips, to minimize local residual stress concentrations.

Similar content being viewed by others

References

Sikulskiy V, Kashcheyeva V, Romanenkov Y, Shapoval A (2017) Study of the process of shape-formation of ribbed double-curvature panels by local deforming. Eastern-Eur J Enterprise Technol 4:43–49. https://doi.org/10.15587/1729-4061.2017.108190

Koehler W, Plege B, Sahm KF, Padmapriya N (2017) Metal forming: specialized procedures for the aircraft industry. In Reference Module in Materials Science and Materials Engineering; Elsevier. https://doi.org/10.1016/B978-0-12-803581-8.01939-1

Li F, Chen S, Shi J, Tian H, Zhao Y (2017) Evaluation and optimization of a hybrid manufacturing process combining wire arc additive manufacturing with milling for the fabrication of stiffened panels. Appl Sci 7:1233. https://doi.org/10.3390/app7121233

Sikulskiy V, Sikulskyi S, Garin V (2021) Investigation into the forming process of wing panel oblique bending by means of rib rolling. Cham pp. 598–608. https://doi.org/10.1007/978-3-030-66717-7_51

Tan J, Zhan M, Liu S (2016) Guideline for forming stiffened panels by using the electromagnetic forces. Metals 6:267. https://doi.org/10.3390/met6110267

Ramati S, Levasseur G, Kennerknecht S (1999) Single piece wing skin utilization via advanced peen forming technology. In Proceedings of the International shot peening conference, Warsaw, Poland, 28–30:1999

Belykh S, Krivenok A, Bormotin K, Stankevich A, Krupskiy R, Mishagin V, Burenin A (2016) Numerical and experimental study of multi-point forming of thick double-curvature plates from aluminum alloy 7075. In Proceedings of the IV Sino-Russian ASRTU Symposium on Advanced Materials and Processing Technology (ASRTU), Ekaterinburg, Russia, 10/12. https://doi.org/10.18502/kms.v1i1.556

Wagoner RH, Wang JF, Li M (2006) Springback. In Metalworking: Sheet Forming, Semiatin, S.L., Ed.; ASM International 14B:0. https://doi.org/10.31399/asm.hb.v14b.a0005131

Sikulskyi V, Sikulskyi S, Maiorova K, Suponina V, Komisarov O (2022) The process of forming integral ribbed panels by sequential local phased deformation with information support. In Proceedings of the Integrated Computer Technologies in Mechanical Engineering - 2021, Cham, 2022// 157–165. https://doi.org/10.1007/978-3-030-94259-5_15.

Сикульский В. [Sikulskiy V.] (2015) Разработка устройств для формообразования и доводки монолитных панелей сложных форм [Design of tools for forming of intergral panels of complex forms]. Вестник Национального технического университета "ХПИ": сборник научных трудов, выпуск: Инновационные технологии и оборудование обработки материалов в машиностроении и металлургии, 24 (1133), 108–120. [Bulletin of National Technical University “KhPI”: collection of scientific papers, series: innovative technologies and equipment for material processing in mechanical engineering and metallurgy, 24(1133):108–120]

Luo H, Li W, Li C, Wan M (2017) Investigation of creep-age forming of aluminum lithium alloy stiffened panel with complex structures and variable curvature. Int J Adv Manuf Technol 91:3265–3271. https://doi.org/10.1007/s00170-017-0004-z

Liu C-G, Li J, Dong Y-N, Zhang X-G, Yue T (2017) Fracture prediction in the forming of aircraft Al stiffeners using multi-point dies. Int J Adv Manuf Technol 90:3109–3118. https://doi.org/10.1007/s00170-016-9634-9

Zhang M, Tian X, Li W, Shi X (2018) An equivalent calculation method for press-braking bending analysis of integral panels. Metals 8:364. https://doi.org/10.3390/met8050364

Sikulskiy V, Sikulskyi S, Kashcheeva V (2018) Modeling of the monolithic panels shaping process in ANSYS. Bull. National Tech. Univ.“KhPI”. Ser.: Innov. Technol. Equipment Handling Mater. Mech. Eng. Metall 23:67–73

Yan Y, Wang H-B, Wan M (2012) FEM modelling for press bend forming of doubly curved integrally stiffened aircraft panel. Trans Nonferrous Met Soc China 22:s39–s47. https://doi.org/10.1016/S1003-6326(12)61681-1

Кишкинa C, Фpиндляндep И, [Kishkina S, Frindliander I] (1983) Toм 4: Aлюминиeвыe и бepилливыe cплaвы [Volume 4: Aluminum and Beryllium Alloys]. In Aвиaциoнныe мaтepиaлы : cпpaвoчник в 9-ти тoмax [Aviation materials: handbook in 9 volumes], Шaлинa, P., [Shalina R.], Ed.; BИAM [Russian Research Institute of Aviation Materials] 522

Department of Defense (2003) Military specification MIL-HDBK-5J, metallic materials and elements for aerospace vehicle structures

Esmaeili F, Zehsaz M, Navid Chakherlou T, Mohammadi S (2015) Fatigue life estimation of double lap simple bolted and hybrid (bolted/bonded) joints using several multiaxial fatigue criteria. Mater Des 67:583–595. https://doi.org/10.1016/j.matdes.2014.11.003

Tekgoz M. (2012) Strength assessment of imperfect stiffened panels using modified stress strain curves. Master’s thesis, department of naval architecture and marine engineering, technical university of Lisbon, Lisbon, Portugal

Grover H. J. (1966) Fatigue of aircraft structures. United States: U.S. Government Printing Office

Zhou W, Shao Z, Yu J, Lin J (2021) Advances and trends in forming curved extrusion profiles. Materials (Basel) 14:1603. https://doi.org/10.3390/ma14071603

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Conceptualization, methodology, and correction of the final manuscript version were performed by all the authors. Numerical modeling, analysis, and the first draft of the manuscript were completed by Valeriy Sikulskiy and Stanislav Sikulskyi. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sikulskiy, V., Sikulskyi, S., Maiorova, K. et al. Modeling the forming process by successive local deforming for monolithic stiffened panels. Int J Adv Manuf Technol 124, 1569–1578 (2023). https://doi.org/10.1007/s00170-022-10582-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10582-9