Abstract

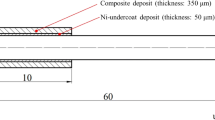

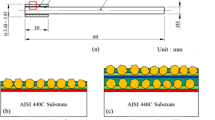

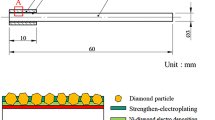

Fabrication and evaluation of electroplated Ni–B-diamond grinding tools made with 3-mm-diameter martensitic AISI 440C rod substrates were performed. With 25-μm-thick layer of Ni deposit serving as the undercoating, Ni–B-diamond composite deposits with a thickness of 300 μm were prepared using intermittent stirring in a Ni–B-diamond plating bath containing synthetic diamond particles ranging between 30 and 40 μm in sizes. The prepared electroplated diamond tools were then post processed by annealing and trimming by means of electrical discharge machining (EDM). Based on experimental results, it was found that the diamond density in a diamond-contained composite deposit depended on the timings of intermittent stirring cycle. The highest diamond density of 829 particles/mm2 can be found in the Ni–B-diamond composite by a stirring cycle with an on-period of 5 s and an off-period of 60 s. To minimize unwanted scale formations, 150 g/L of diamond particles and 3 g/L of sodium dodecyl sulfate (SDS) were use in the plating bath. An EDM current of 6 A or more was necessary to obtain a rectangular lateral profile for machining. A suitable composite hardness for high grinding performance can be achieved with 0.43 wt% (2.29 at%) of B content in the Ni–B-diamond composite plated at a high current density and an annealing temperature between 400 and 500 °C for 30 min. Slot grinding tests were performed on Al2O3 plates and maximum ground lengths of more than 1000 mm were achieved. Slot width reduction due to tool wear was well within 120 μm. The main cause of tool failure was concluded to be composite deposit peeling or broken off from the substrate.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Wu Y, Luo J, Wang Y et al (2019) Critical effect and enhanced thermal conductivity of Cu-diamond composites reinforced with various diamond prepared by composite electroplating. Ceram Int 45:13225–13234. https://doi.org/10.1016/j.ceramint.2019.04.008

Lee EC, Moon IT (2002) Electrolytic codeposition of diamond particles with nickel and cobalt metals. Plat Surf Finish 89(12):55–59

Huang CA, Yang SW, Shen CH et al (2019) Fabrication and evaluation of electroplated Ni–diamond and Ni–B–diamond milling tools with a high density of diamond particles. Int J Adv Manuf Technol 104:2981–2989. https://doi.org/10.1007/s00170-019-04174-3

Pushpavanam M, Manikandan H, Ramanathan K (2007) Preparation and characterization of nickel-cobalt-diamond electro-composites by sediment co-deposition. Surf Coatings Technol 201:6372–6379. https://doi.org/10.1016/j.surfcoat.2006.12.004

Wang L, Gao Y, Liu H et al (2005) Effects of bivalent Co ion on the co-deposition of nickel and nano-diamond particles. Surf Coatings Technol 191:1–6. https://doi.org/10.1016/j.surfcoat.2004.03.047

Lee KH, Chang D, Kwon SC (2005) Properties of electrodeposited nanocrystalline Ni-B alloy films. Electrochim Acta 50:4538–4543. https://doi.org/10.1016/j.electacta.2004.03.067

Ogihara H, Udagawa K, Saji T (2012) Effect of boron content and crystalline structure on hardness in electrodeposited Ni-B alloy films. Surf Coatings Technol 206:2933–2940. https://doi.org/10.1016/j.surfcoat.2011.12.025

Krishnaveni K, Sankara Narayanan TSN, Seshadri SK (2006) Electrodeposited Ni-B coatings: formation and evaluation of hardness and wear resistance. Mater Chem Phys 99:300–308. https://doi.org/10.1016/j.matchemphys.2005.10.028

Arai S, Kasai S, Shohji I (2010) Boron particle composite plating with Ni–B alloy matrix. J Electrochem Soc 157. https://doi.org/10.1149/1.3271099

Chang CR, Hou KH, Ger MD, Wang JR (2017) Characteristics of nickel boron coatings prepared by direct current electrodeposition technique. Int J Electrochem Sci 12:2055–2069. https://doi.org/10.20964/2017.03.17

López JR, Méndez PF, Pérez-Bueno JJ, et al (2016) The effect of boron content, crystal structure, crystal size on the hardness and the corrosion resistance of electrodeposited Ni-B coatings. Int J Electrochem Sci 11:4231–4244. https://doi.org/10.20964/2016.06.23

Chen TJ, Chiou YC, Lee RT (2009) Grinding characteristics of diamond film using composite electro-plating in-process sharpening method. Int J Mach Tools Manuf 49:470–477. https://doi.org/10.1016/j.ijmachtools.2009.01.002

Ko TJ, Yoon IJ (2012) Mill-grinding with electroplated diamond abrasives for ceramic cutting. Int J Precis Eng Manuf 13:5–10. https://doi.org/10.1007/s12541-012-0001-y

Liang G, Zhou X, Zhao F (2016) The grinding surface characteristics and evaluation of particle-reinforced aluminum silicon carbide. Sci Eng Compos Mater 23:671–676. https://doi.org/10.1515/secm-2014-0377

Liang Z, Du Y, Ma Y et al (2022) Development of polycrystalline diamond micro end mill for milling-grinding combined machining of cemented carbide. J Manuf Process 79:844–853. https://doi.org/10.1016/j.jmapro.2022.05.020

Huang CA, Shen CH, Yang SW et al (2020) Fabrication and evaluation of electroplated diamond grinding rods strengthened with Cr-C deposit. Int J Adv Manuf Technol 110:2541–2550. https://doi.org/10.1007/s00170-020-05989-1

Choudhary A, Paul S (2020) The wear mechanisms of diamond grits in grinding of alumina and yttria-stabilized zirconia under different cooling-lubrication schemes. Wear 454–455:203315. https://doi.org/10.1016/j.wear.2020.203315

Cao Y, Zhao B, Ding W et al (2021) On the tool wear behavior during ultrasonic vibration-assisted form grinding with alumina wheels. Ceram Int 47:26465–26474. https://doi.org/10.1016/j.ceramint.2021.06.059

Malevich N, Müller CH, Dreier J et al (2021) Experimental and statistical analysis of the wear of diamond impregnated tools. Wear 468–469:203574. https://doi.org/10.1016/j.wear.2020.203574

Yildiz RA, Genel K, Gulmez T (2017) Effect of heat treatments for electroless deposited Ni-B and Ni-W-B coatings on 7075 Al alloy. Int J Mater Mech Manuf 5:83–86. https://doi.org/10.18178/ijmmm.2017.5.2.295

Lu J, Yang QH, Zhang Z (2010) Effects of additives on nickel electrowinning from sulfate system. Trans Nonferrous Met Soc China 20:s97–s101. https://doi.org/10.1016/S1003-6326(10)60020-9

Huang CA, Hsu CC, Kuo HH (2003) The surface characteristics of P/M high-speed steel (ASP 23) multi-cut with wire electrical discharge machine (WEDM). J Mater Process Technol 140:298–302. https://doi.org/10.1016/S0924-0136(03)00765-9

Hall CE, Weber RL (1954) Introduction to electron microscopy. Am J Phys 22:97. https://doi.org/10.1119/1.1933636

Acknowledgements

The authors, Ching An Huang, Chia Hsuan Shen, and Po Liang Lai, thank the Chang Gung Medical Foundation for supporting this work under contract number of CMRPD2L0091.

Funding

This work was supported by Chang Gung Medical Foundation in Taiwan (Grant number CMRPD2L0091). The grant was awarded to Ching An Huang.

Author information

Authors and Affiliations

Contributions

All authors contributed to study conceptualization and design. Investigation and data curation were performed by Chung Juei Lee. Formal analysis was performed by Ching An Huang, Chia Hsuan Shen, Hai Wang and Chung Juei Lee. The original draft was written by Ching An Huang. Manuscript review and editing were performed by Chia Hsuan Shen. All authors read and approved the final manuscript. This project was supervised by Ching An Huang.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, C.A., Shen, C.H., Lee, C.J. et al. Grinding performances of electroplated Ni–B-diamond tools prepared through composite electroplating with intermittent stirring. Int J Adv Manuf Technol 124, 1891–1903 (2023). https://doi.org/10.1007/s00170-022-10574-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10574-9