Abstract

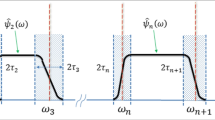

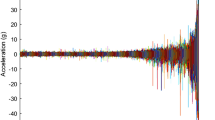

In the context of Industry 4.0, condition-based maintenance (CBM) for complex systems is essential in order to identify failures and mitigate them. After the identification of a sensor set that guarantees the system monitoring, three main problems must be addressed for effective CBM: (i) collection of the right data; (ii) choice of the optimal technique to identify the specific dataset; (iii) correct classification of the results. The solutions currently used are typically data driven and, therefore, the results are variable, as it is sometimes challenging to identify a pattern for all specific failures. This paper presents a solution that combines a data driven approach with an in-depth knowledge of the mechanical system’s behaviour. The choice of the right sensor set is calculated with the aid of the software MADe (Maintenance Aware Design environment), whereas the optimal dataset identification technique is pursued with a second tool called Syndrome Diagnostics. After an overview of such methodology, this work also presents RSGWPT (redundant second-generation wavelet packaged transform) analysis to show different possible outcomes depending on the available sensor data and to tailor a detection technique to a given dataset. Supervised and unsupervised learning techniques are tested to obtain either an anomaly detection or a failure identification depending on the chosen sensor set. By using the described method, it is possible to identify potential failures in the system so to awarely implement the optimal maintenance actions.

Similar content being viewed by others

Data availability

A folder containing the source code can be downloaded at https://doi.org/10.17632/64ry38sfkw.2.

Code availability

As above, refer to https://doi.org/10.17632/64ry38sfkw.2.

References

Yan J, Meng Y, Lu L, Li L (2017) Industrial big data in an industry 4.0 environment: challenges, schemes, and applications for predictive maintenance. IEEE Access 5:23484–23491

Kang HS, Lee J, Choi S, Kim H, Park JH, Son JY, Kim BH, Noh SD (2016) Smart manufacturing: past research, present findings, and future directions. Int J Precis Eng Manuf-Green Technol 3(1):111–128

Yi X, Liu F, Liu J, Jin H (2014) Building a network highway for big data: architecture and challenges. IEEE Netw 28(4):5–13

Hess A, Stecki J, Clark S (2008) The maintenance aware design environment: development of an aerospace phm software tool. In: Proceedings of PHM08

Karnopp DC, Rosenberg RC (1968) Analysis and simulation of multiport systems: the bond graph approach to physical system dynamics. MIT Press, Cambridge

Borutzky W (2010) Bond graph methodology, development and analysis of multidisciplinary dynamic system models. Springer, Berlin Heidelberg

Karnopp DC, Margolis DL, Rosenberg RC (2012) System dynamics, modeling, simulation and control of mechatronic systems. Wiley, New York

Das S (2009) Mechatronic modeling and simulation using bond graphs. CRC Press, Boca Raton

Hrovat D, Tobler WE (1991) Bond graph modeling of automotive power trains. J Frankl Inst-Eng Appl Math 328:623–662

Alashter A, Cao Y, Rabeyee K, Alabied S, Gu F, Ball AD (2020) Bond graph modelling for condition monitoring of induction motors. In: Ball A, Gelman L, Rao BKN (eds) Advances in asset management and condition monitoring. Springer International Publishing, pp 511–523

Prakash O, Samantaray AK, Bhattacharyya R (2018) Model-based multi-component adaptive prognosis for hybrid dynamical systems. Control Eng Pract 72:1–18

Park Y-J, Fan S-KS, Hsu C-Y (2020) A review on fault detection and process diagnostics in industrial processes. Processes 8(9)

Wu D, Coatanea E, Wang GG (2019) Employing knowledge on causal relationship to assist multidisciplinary design optimization. J Mech Des Trans ASME 141(4)

Mokhtarian H, Coatanea E, Paris H (2017) Function modeling combined with physics-based reasoning for assessing design options and supporting innovative ideation. Artif Intell Eng Des Anal Manuf 31:476–500

Coatanea E, Roca R, Mokhtarian H, Mokammel F, Ikkala K (2016) A conceptual modeling and simulation framework for system design. Comput Sci Eng 18(4):42–52

Wu D, Coatanea E, Wang GG (2017) Dimension reduction and decomposition using causal graph and qualitative analysis for aircraft concept design optimization vol 2B-2017

Rudov-Clark S, Ryan A, Stecki C, Stecki J, Hess A (2010) Extending advanced failure effects analysis to support prognostics and health management. In: 2010 Prognostics and system health management conference, pp 1–5

Shanna R-C, Ryan AJ, Stecki C, Stecki JS (2009) Automated design and optimisation of sensor sets for condition-based monitoring

Saruhan H, Sandemir S, Qicek A, Uygur I (2014) Vibration analysis of rolling element bearings defects. J Appl Res Technol 12(3):384–395

Al-Badour F, Sunar M, Cheded L (2011) Vibration analysis of rotating machinery using time-frequency analysis and wavelet techniques:2083–2101

Loutas T, Kostopoulos V (2012) Utilising the wavelet transform in condition-based maintenance: a review with applications. Department of Mechanical Engineering and Aeronautics University of Patras, Rio

Wai Keng N, Leong M, Hee L, Abdelrhman A (2013) Wavelet analysis: mother wavelet selection methods. Appl Mech Mater 393:953–958

Steinbuch M, Merry RJE (2005) Wavelet theory and applications. Eindhoven University of Technology Department of Mechanical Engineering Control Systems Technology Group Eindhoven

Lemaster RL (2012) The use of the wavelet transform to extract additional information on surface quality from optical profilometers. INTECH Open Access Publisher

Tong Q, Cao J, Han B, Zhang X, Nie Z, Wang J, Lin Y, Zhang W (2017) A fault diagnosis approach for rolling element bearings based on RSGWPT-LCD bilayer feature screening and extreme learning machine. IEEE Access PP:1–1

Liu Z, Guo W, Hu J, Ma W (2017) A hybrid intelligent multi-fault detection method for rotating machinery based on RSGWPT, KPCA and twin SVM. ISA Trans 66:249–261

Hongkai J, Zhengjia H, Chendong D, Peng C (2006) Gearbox fault diagnosis using adaptive redundant lifting scheme. Mech Syst Signal Process 20(8):1992–2006

Caesarendra W, Tjahjowidodo T (2017) A review of feature extraction methods in vibration-based condition monitoring and its application for degradation trend estimation of low-speed slew bearing. Machines 5 (4):21

Maltoni D (2019) Riduzione dimensionalitÃ. In: Dispense di machine learning

Sathya R, Abraham A (2013) Comparison of supervised and unsupervised learning algorithms for pattern classification. Int J Adv Res Artif Intell 2(02)

Vapnik V (1998) Statistical learning theory 16(01). Wiley, New York

Cortes C, Vapnik V (1995) Support vector networks. Mach Learn 20:273–297

Fernandez R (2020) Predicting time series with a local support vector regression machine

Tefas A, Kotropoulos C, Pit I (2000) Enhancing the performance of elastic graph matching for face authentication by using support vector machines. IEEE Trans Pattern Anal Mach Intell - PAMI

Veropoulos K, Cristianini N, Campbell C (1999) The application of support vector machines to medical decision support: a case study. Adv Course Artif Intell

Evgeniou T, Pontil M (2001) Support vector machines: theory and applications. In: Paliouras G, Karkaletsis V, Spyropoulos CD (eds) Machine learning and its applications, vol 2049. Springer, Berlin Heidelberg, pp 249–257. Series Title: Lecture Notes in Computer Science

Pedregosa F, Varoquaux G, Gramfort A, Michel V, Thirion B, Grisel O, Blondel M, Prettenhofer P, Weiss R, Dubourg V, Vanderplas J, Passos A, Cournapeau D, Brucher M, Perrot M, Duchesnay E (2011) Scikit-learn: machine learning in Python. J Mach Learn Res 12:2825–2830

Müllner D (2011) Modern hierarchical, agglomerative clustering algorithms. arXiv:1109.2378 [cs, stat]

Likas A, Vlassis N, Verbeek JJ (2003) The global k-means clustering algorithm. Pattern Recogn 36(2):451–461

Casdagli M, Eubank S, Farmer J, Gibson J (1991) State space reconstruction in the presence of noise. Physica D: Nonlinear Phenom 51(1):52–98

Qiu H, Lee J, Lin J, Yu G (2006) Wavelet filter-based weak signature detection method and its application on rolling element bearing prognostics. J Sound Vib 289(4):1066–1090

Goutte C, Gaussier E (2005) A probabilistic interpretation of precision, recall and f-score, with implication for evaluation. In: Proceedings of the 27th European conference on IR research (ECIR), pp 345–359

Acknowledgements

A reduced version of this paper has been presented and published at the 2020 European Conference of the PHM Society (https://papers.phmsociety.org/index.php/phme/article/view/1255) as an open-access article distributed under the terms of the Creative Commons Attribution 3.0 United States License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. The present version of the paper enlarges the above-mentioned work and also adds the source code to be freely used by the research community.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception. C.G. and E.O. have written the source code, M.B., G.B. and R.R. have conceived the methodological framework; J.S. has provided knowledge about MADe software. The manuscript has been written by all authors. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gattino, C., Ottonello, E., Baggetta, M. et al. Application of AI failure identification techniques in condition monitoring using wavelet analysis. Int J Adv Manuf Technol 125, 4013–4026 (2023). https://doi.org/10.1007/s00170-022-10549-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10549-w