Abstract

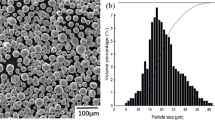

Selective laser melting (SLM) is prevalent as one additive manufacturing (AM) technique to produce metallic components. In this study, a modified GTN (Gurson-Tvergaard-Needleman) model was used to characterize void growth, nucleation, and shear mechanism to predict the ductile fracture behavior of SLM-fabricated Ti6Al4V alloys under uniaxial stress states. An intelligence approach obtained by an artificial neural network (ANN) in conjunction with particle swarm optimization (PSO) algorithms which optimized modified GTN model parameters and found relations between input and output data. In order to assess the accuracy of the results, the PSO suggested parameters were applied to finite element simulation and checked by experimental results in each step; then, the machine was trained by the last data to find desired optimum parameters. The final results showed that the damage and fracture behavior of SLM-fabricated Ti6Al4V alloys under uniaxial stress states are correctly predicted by GTN-modified model and hybrid ANN-PSO optimized parameters.

Similar content being viewed by others

Availability of data and material

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

Code availability

The code of this study is available from the corresponding author, upon reasonable request.

References

DebRoy T et al (2018) Additive manufacturing of metallic components–process, structure and properties. Prog Mater Sci 92:112–224

Campanelli SL, Contuzzi N, Ludovico AD, Caiazzo F, Cardaropoli F, Sergi V (2014) Manufacturing and characterization of Ti6Al4V lattice components manufactured by selective laser melting. Materials 7(6):4803–4822

Jiménez A, Bidare P, Hassanin H, Tarlochan F, Dimov S, Essa K (2021) Powder-based laser hybrid additive manufacturing of metals: a review. The Int J Adv Manuf Technol 114(1):63–96

Lütjering G, Williams J (2007) Titanium (engineering materials and processes), 2nd edn. Springer-Verlag, Berlin

Elahinia M, Hashemi SM, Parvizi S, Baghbanijavid H, Tan AT, Nematollahi M, Ramazani A, Fang NX. Computational modeling of process-structure-property-performance relationships in metal additive manufacturing: a review. Int Mater Rev 67(1):Jan-46

Ai L, Gao X-L (2017) Micromechanical modeling of 3D printable interpenetrating phase composites with tailorable effective elastic properties including negative Poisson’s ratio. J Micromech Mol Phys 2(04):1750015

Romano S, Brückner-Foit A, Brandão A, Gumpinger J, Ghidini T, Beretta S (2018) Fatigue properties of AlSi10Mg obtained by additive manufacturing: defect-based modelling and prediction of fatigue strength. Eng Fract Mech 187:165–189

Gong H, Chen C, Yao Y (2019) A void evolution-based damage model for ductile fracture of metallic materials. J Micromech Mol Phys 4(04):1950008

Zhao Z, Chen J, Tan H, Lin X, Huang W (2017) Evolution of plastic deformation and its effect on mechanical properties of laser additive repaired Ti64ELI titanium alloy. Opt Laser Technol 92:36–43

Xia Z, He Z, Wang Q, Wang Y (2020) A new finite element model with manufactured error for additive manufacturing. Comput Model Eng Sci 124(2):703–720

Liu J, Stevens E, Yang Q, Chmielus M, To AC (2017) An analytical model of the melt pool and single track in coaxial laser direct metal deposition (LDMD) additive manufacturing. J Micromech Mol Phys 2(04):1750013

Wilson-Heid AE, Beese AM (2019) Fracture of laser powder bed fusion additively manufactured Ti–6Al–4V under multiaxial loading: calibration and comparison of fracture models. Mater Sci Eng A 761:137967

Qattawi A, Alrawi B, Guzman A (2017) Experimental optimization of fused deposition modelling processing parameters: a design-for-manufacturing approach. Procedia Manuf 10:791–803

Pal S et al (2020) Evolution of the metallurgical properties of Ti-6Al-4V, produced with different laser processing parameters, at constant energy density in selective laser melting. Results Phys 17:103186

Saghaian SE et al (2022) Effect of hatch spacing and laser power on microstructure, texture, and thermomechanical properties of laser powder bed fusion (L-PBF) additively manufactured NiTi. Opt Laser Technol 149:107680

Andani MT, Ghodrati M, Karamooz-Ravari MR, Mirzaeifar R, Ni J (2019) Damage modeling of metallic alloys made by additive manufacturing. Mater Sci Eng A 743:656–664

Lee S, Rasoolian B, Silva DF, Pegues JW, Shamsaei N (2021) Surface roughness parameter and modeling for fatigue behavior of additive manufactured parts: a non-destructive data-driven approach. Addit Manuf 46:102094

Salman O et al (2019) Impact of the scanning strategy on the mechanical behavior of 316L steel synthesized by selective laser melting. J Manuf Process 45:255–261

Zhang Y, Bernard A, Harik R, Karunakaran K (2017) Build orientation optimization for multi-part production in additive manufacturing. J Intell Manuf 28(6):1393–1407

Zaldivar R, Witkin D, McLouth T, Patel D, Schmitt K, Nokes J (2017) Influence of processing and orientation print effects on the mechanical and thermal behavior of 3D-printed ULTEM® 9085 material. Addit Manuf 13:71–80

Seifi M, Christiansen D, Beuth J, Harrysson O, Lewandowski JJ (2016) Process mapping, fracture and fatigue behavior of Ti-6Al-4V produced by EBM additive manufacturing. In: Proceedings of the 13th World Conference on Titanium, vol. 232: Citeseer, pp. 1373–1377

Kumar P, Prakash O, Ramamurty U (2018) Micro-and meso-structures and their influence on mechanical properties of selectively laser melted Ti-6Al-4V. Acta Mater 154:246–260

Nalli F, Cortese L, Concli F (2021) Ductile damage assessment of Ti6Al4V, 17–4PH and AlSi10Mg for additive manufacturing. Eng Fract Mech 241:107395

Waqar S, Guo K, Sun J (2021) FEM analysis of thermal and residual stress profile in selective laser melting of 316L stainless steel. J Manuf Process 66:81–100

Aktürk M, Boy M, Gupta MK, Waqar S, Krolczyk GM, Korkmaz ME (2021) Numerical and experimental investigations of built orientation dependent Johnson-Cook model for selective laser melting manufactured AlSi10Mg. J Market Res 15:6244–6259

McClintock F (1968) Erratum: a criterion for ductile fracture by the growth of holes. J Appl Mech 35:363–371

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields∗. J Mech Phys Solids 17(3):201–217

Hancock J, Mackenzie A (1976) On the mechanisms of ductile failure in high-strength steels subjected to multi-axial stress-states. J Mech Phys Solids 24(2–3):147–160

Gholipour H, Biglari F, Nikbin K (2019) Experimental and numerical investigation of ductile fracture using GTN damage model on in-situ tensile tests. Int J Mech Sci 164:105170

Cao M-Y, Hu H, Jia X-D, Han X-B, Yao P-L (2020) FE-DE coupling analysis of AZ31B sheet solid granule medium forming based on GTN model. Int J Adv Manuf Technol 111(5):1617–1626

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: Part I—Yield criteria and flow rules for porous ductile media. ASME J Eng Mater Technol 99(1):2–15

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32(1):157–169

Gatea S, Ou H, Lu B, McCartney G (2017) Modelling of ductile fracture in single point incremental forming using a modified GTN model. Eng Fract Mech 186:59–79

Yang X, Li Y, Jiang W, Duan M-G, Chen D, Li B (2021) Ductile fracture prediction of additive manufactured Ti6Al4V alloy based on an extended GTN damage model. Eng Fract Mech 256:107989

Wilson-Heid AE, Furton ET, Beese AM (2021) Contrasting the role of pores on the stress state dependent fracture behavior of additively manufactured low and high ductility metals. Materials 14(13):3657

Prieto A et al (2016) Neural networks: an overview of early research, current frameworks and new challenges. Neurocomputing 214:242–268

Sondagar H, Bhadauria S, Sharma V (2021) Artificial neural network (ANN) based prediction of process parameters in additive manufacturing. In: IOP Conference Series: Materials Science and Engineering, vol. 1136, no. 1: IOP Publishing, p. 012026

Tsai K-M, Luo H-J (2017) An inverse model for injection molding of optical lens using artificial neural network coupled with genetic algorithm. J Intell Manuf 28(2):473–487

Mehrpouya M, Gisario A, Rahimzadeh A, Nematollahi M, Baghbaderani KS, Elahinia M (2019) A prediction model for finding the optimal laser parameters in additive manufacturing of NiTi shape memory alloy. Int J Adv Manuf Technol 105(11):4691–4699

Mehrpouya M, Gisario A, Nematollahi M, Rahimzadeh A, Baghbaderani KS, Elahinia M (2021) The prediction model for additively manufacturing of NiTiHf high-temperature shape memory alloy. Mater Today Commun 26:102022

Stathatos E, Vosniakos G-C (2019) Real-time simulation for long paths in laser-based additive manufacturing: a machine learning approach. Int J Adv Manuf Technol 104(5):1967–1984

Kwon O et al (2020) A deep neural network for classification of melt-pool images in metal additive manufacturing. J Intell Manuf 31(2):375–386

Paermentier B, Debruyne D, Talemi R (2021) A machine learning based sensitivity analysis of the GTN damage parameters for dynamic fracture propagation in X70 pipeline steel. Int J Fract 227(1):111–132

Rao RV, Kalyankar V (2014) Optimization of modern machining processes using advanced optimization techniques: a review. Int J Adv Manuf Technol 73(5):1159–1188

Shafaie M, Biglari FR, Keneshlou M, Gharib AR (2022) Blank shape optimization in sheet metal processing using a hybrid fuzzy-sensitivity method. Int J Comput Integr Manuf, 1–13

Zhu X, Ma B, Su G, Hu Y, Liu D (2022) Blank design method for C-section profile ring rolling based on FEM and RSM. Alex Eng J

Needleman A, Tvergaard V (1984) An analysis of ductile rupture in notched bars. J Mech Phys Solids 32(6):461–490

Needleman A, Tvergaard V (1992) Analyses of plastic flow localization in metals. ASME Appl Mech Rev 45(3S):S3–S18

Holte I, Niordson C, Nielsen K, Tvergaard V (2019) Investigation of a gradient enriched Gurson-Tvergaard model for porous strain hardening materials. Eur J Mech-A/Solids 75:472–484

Tvergaard V (1989) Material failure by void growth to coalescence. Adv Appl Mech 27:83–151

Nahshon K, Hutchinson J (2008) Modification of the Gurson model for shear failure. Eur J Mech-A/Solids 27(1):1–17

Popovich A, Sufiiarov V, Borisov E, Polozov IA (2015) Microstructure and mechanical properties of Ti-6Al-4V manufactured by SLM. In: Key Engineering Materials. Trans Tech Publications Ltd 651:677–682

Riipinen T (2020) Heat treatment of AM alloys. VTT Technical Research Centre of Finland. VTT Research Report No. VTT-R-00899-20

Yadollahi A, Shamsaei N (2017) Additive manufacturing of fatigue resistant materials: challenges and opportunities. Int J Fatigue 98:14–31

Pan B, Qian K, Xie H, Asundi A (2009) Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review. Meas Sci Technol 20(6):062001

Kumar SL, Aravind H, Hossiney N (2019) Digital image correlation (DIC) for measuring strain in brick masonry specimen using Ncorr open source 2D MATLAB program. Results Eng 4:100061

Abaqus G (2019) Abaqus 6.19. Dassault Systemes Simulia Corporation, Providence

Matlab V (2019) 9.6. 0.1072779 (R2019a). The MathWorks Inc., Natick

Sarparast M, Ghoreishi M, Jahangirpoor T, Tahmasbi V (2020) Experimental and finite element investigation of high-speed bone drilling: evaluation of force and temperature. J Braz Soc Mech Sci Eng 42(6):1–9

Pujol J (2007) The solution of nonlinear inverse problems and the Levenberg-Marquardt method. Geophysics 72(4):W1–W16

Garcia-Gonzalo E, Fernandez-Martinez JL (2012) A brief historical review of particle swarm optimization (PSO). J Bioinform Intell Control 1(1):3–16

Zhu H, Wang Y, Wang K, Chen Y (2011) Particle swarm optimization (PSO) for the constrained portfolio optimization problem. Expert Syst Appl 38(8):10161–10169

Marini F, Walczak B (2015) Particle swarm optimization (PSO). A tutorial. Chemom Intell Lab Syst 149:153–165

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shafaie, M., Khademi, M., Sarparast, M. et al. Modified GTN parameters calibration in additive manufacturing of Ti-6Al-4 V alloy: a hybrid ANN-PSO approach. Int J Adv Manuf Technol 123, 4385–4398 (2022). https://doi.org/10.1007/s00170-022-10522-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10522-7