Abstract

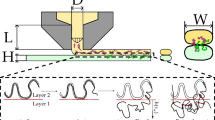

Due to the complexity of extrusion 3D printing objects and lack of universal parameters, there are few classified statistics or quantitative description for the “extrudability” of material with shear thinning properties. In order to systematically study the rheological properties of extrudable materials and establish a unified criterion or quality evaluation standard from the basic process theory, a Nishihara rheological constitutive model based on visco-elastic and visco-plastic characteristics of materials is explored to predict and investigate the extrusion performance of four typical dispersed-continuous phase binary mixture. The creep model result shows that, expect for the gelatin network-water system with almost complete elastic behavior, the material with shear thinning property based on Nishihara model is in good agreement with the experimental results. In the extrusion process, the shear stress is related to the advancing speed, material viscosity, and nozzle size. The effects of advancing speed and nozzle size on shear stress show antagonistic characteristics in a certain range; that is, the velocity gradient is the dominant factor at lower extrusion speed, and the dynamic viscosity is the dominant factor at higher extrusion speed. In terms of extrusion properties, the material system with smaller yield strain/stress has the least obvious extrusion delay characteristics, and is easier to extrude under the condition of the same material strength.

Similar content being viewed by others

Data availability

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

Abbreviations

- \(H\) :

-

Elastic element

- \(N\) :

-

Viscous element

- \(S\) :

-

Plastic element

- \(\sigma\) :

-

Stress of model

- \(\varepsilon\) :

-

Strain of model

- \({\sigma }_{s}\) :

-

Yield stress of viscoplastic element,

- \({k}_{1}\), \({k}_{2}\) :

-

Elastic coefficient of elastic element and viscoelastic element respectively

- \({\eta }_{1}\), \({\eta }_{2}\) :

-

Viscous coefficient of viscoelastic element and viscoplastic element respectively

- \(\dot{\sigma }\), \(\ddot{\sigma }\) :

-

Time derivative of model stress

- \(\dot{\varepsilon }\), \(\ddot{\varepsilon }\) :

-

Time derivative of model strain

- \({\sigma }_{0}\) :

-

Transient stress

- \(t\) :

-

Loading time

- \(\gamma\) :

-

Shear stress

- \(\eta\) :

-

Dynamic viscosity

- \(u\) :

-

Advancing speed

- \(y\) :

-

Size of nozzle

References

Mironov V, Visconti RP, Kasyanov V et al (2009) Organ printing: Tissue spheroids as building blocks. Biomaterials 30(12):2164–2174

Ginestra AL (2019) Cell Bioprinting: The 3D-Bioplotter™ case. Materials 12(23):4005

Hölzl K, Lin S, Tytgat L et al (2016) Bioink properties before, during and after 3D bioprinting. Biofabrication 8(3):032002

He Y, Yang F, Zhao HM et al (2016) Research on the printability of hydrogels in 3D bioprinting. Sci Rep 6:29977

Tabriz AG, Hermida MA, Leslie NR et al (2015) Three-dimensional bioprinting of complex cell laden alginate hydrogel structures. Biofabrication 7(4):045012

Guiseppe MD, Law N, Webb B et al (2018) Mechanical behaviour of alginate-gelatin hydrogels for 3D bioprinting. J Mech Behav Biomed Mater 79:150–157

Pan T, Song W, Cao X et al (2016) 3D bioplotting of gelatin/alginate scaffolds for tissue engineering: influence of crosslinkingdegree and pore architecture on physicochemical properties[J]. Journal of Materials Science & Technology 32(9):889–900

Hinton TJ, Jallerat Q, Palchesko RN et al (2015) Three-dimensional printing of complex biological structures by freeform reversible embedding of suspended hydrogels. Sci Adv 1(9):e1500758–e1500758

Zhou X, Zhu W, Nowicki M et al (2016) 3D bioprinting a cell-laden bone matrix for breast cancer metastasis study. ACS appliedmaterials & interfaces 8(44):30017–30026

Zhao VXT, Wong TI, Zhou X (2017) 3D Printing of Biosamples: A Concise Review[J]. Journal of Molecular and EngineeringMaterials 5(02):1740002

Chimene D, Peak CW, Gentry JL et al (2018) Nanoengineered ionic–covalent entanglement (NICE) bioinks for 3D bioprinting. ACS applied materials & interfaces 10(12):9957–9968

Ahlfeld T, Cidonio G, Kilian D et al (2017) Development of a clay based bioink for 3D cell printing for skeletal application. Biofabrication 9(3):3702817715654

Bairagi S, Vinchurkar K, Kushwah R et al (2018) 3D printing: a review. J Harmonized Res Pharm 7(4):98

Serra T, Planell JA, Navarro M (2013) High-resolution PLA-based composite scaffolds via 3-D printing technology. Acta Biomater 9(3):5521–5530

Tekinalp HL, Kunc V, Velez-Garcia GM et al (2014) Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos Sci Technol 105(dec):144–150

Postiglione G, Natale G, Griffini G et al (2015) Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nanocomposites via liquid deposition modeling. Compos A Appl Sci Manuf 76:110–114

Eckel ZC, Zhou C, Martin JH et al (2016) Additive manufacturing of polymer-derived ceramics[J]. Science 351(6268):58–62

Derby B (2015) Additive manufacture of ceramics components by inkjet printing. Engineering 1(1):113–123

Li X, Gao M, Jiang Y (2016) Microstructure and mechanical properties of porous alumina ceramic prepared by a combination of 3–D printing and sintering. Ceram Int 42(10):12531–12535

Maurath J, Willenbacher N (2017) 3D printing of open-porous cellular ceramics with high specific strength. Journal of theEuropean Ceramic Society 37(15):4833–4842

Tavenas F et al (1978) Creep behaviour of an undisturbed lightly overconsolidated clay. Can Geotech J 15(3):402–423

Grutin ME, Spear K (1983) On the relationship between the logarithmic strain rate and the stretching tensor. Int J Solids Struct 19(5):437–444

Feda J (1992) Creep of soils: and related phenomena. Elsevier.

Ollier RP et al (2021) Improved creep performance of melt-extruded polycaprolactone/organo-bentonite nanocomposites. J Appl Polym Sci 138(38):50961

Güneyisi E et al (2016) Evaluation of the rheological behavior of fresh self-compacting rubberized concrete by using the Herschel-Bulkley and modified Bingham models. Arch Civil Mech Eng 16(1):9–19

Ou Z-F, Fang Y-G (2017) The influence of organic matter content on the rheological model parameters of soft clay. Soil Mech Found Eng 54(4):283–288

Pronk AC (2006) The Huet-Sayegh model: a simple and excellent rheological model for master curves of asphaltic mixes. Asphalt concrete: simulation, modeling, and experimental characterization 73–82

Duty C et al (2018) What makes a material printable? A viscoelastic model for extrusion-based 3D printing of polymers. J Manuf Process 35:526–537

Hossain M, Navaratne R, Perić D (2020) 3D printed elastomeric polyurethane: viscoelastic experimental characterizations and constitutive modelling with nonlinear viscosity functions. Int J Non-Linear Mech 126:103546

Ibrulj J et al (2021) Numerical and experimental investigations of polymer viscoelastic materials obtained by 3D printing. Polymers 13(19):3276

Mezger TG (2006) The Rheology Handbook: For users of rotational and oscillatory rheometers[J]. Vincentz network GmbH & Co.KG, Hannover, Germany

Ferry JD (1980) Viscoelastic properties of polymers. John Wiley & Sons

Huang X, Zhou S, Sun G et al (2015) Topology optimization for microstructures of viscoelastic composite materials[J]. Comput Methods Appl Mech Eng 283:503–516

Szczesniak AS, Brandt MA, Friedman HH (1963) Development of standard rating scales for mechanical parameters of texture and correlation between the objective and the sensory methods of texture evaluation[J]. J Food Sci 28:397–403

Steffe JF, Daubert CR (2006) Bioprocessing pipelines: rheology and analysis, Freeman Press.

Tabilo-Munizaga G, Barbosa-Cánovas GV (2005) Rheology for the food industry. J Food Eng 67:147–156

Tomás H, Alves CS, Rodrigues J (2018) Laponite®: a key nanoplatform for biomedical applications? Nanomed: Nanotechnol Biol Med 14(7):2407–2420

Peak CW, Stein J, Gold KA et al (2018) Nanoengineered colloidal inks for 3D bioprinting. Langmuir 34(3):917–925

Das SS et al (2019) Laponite-based nanomaterials for biomedical applications: a review. Curr Pharm Design 25(4):424–443

Pan Y, Li H, Liu Y et al (2020) Effect of holding time during sintering on microstructure and properties of 3D printed alumina ceramics. Front Mater 7:54

Mariani M et al (2021) 3D printing of fine alumina powders by binder jetting. J Eur Ceram Soc 41(10):5307–5315

Müller M, Becher J, Schnabelrauch M et al (2015) Nanostructured pluronic hydrogels as bioinks for 3D bioprinting. Biofabrication 7(3):035006

PJ RJ, Oluwafemi OS, Thomas S et al (2022) Recent advances in drug delivery nanocarriers incorporated in temperature sensitive Pluronic F-127–A critical review. J Drug Delivery Sci Technol 103390

He Q, Huang Y, Wang S (2018) Hofmeister effect-assisted one step fabrication of ductile and strong gelatin hydrogels. Adv Funct Mater 28(5):1705069.1-1705069.10

Alipal J et al (2021) A review of gelatin: properties, sources, process, applications, and commercialisation. MaterToday: Proc 42:240–250

Xiao C, Wang X, Xu C et al (2008) Method to identify rheological models by unified rheological model theory and case study[J]. Chin J Rock Mech Eng 08:1594–1600

Acknowledgements

The authors would like to thank the Biomaterials and Regenerative Medicine Lab of DUT and all the staffs of the subject group for their patient and attentive help.

Funding

This study was supported by the Special Fund for Comprehensive Industrial Technology Innovation Center Building (grant no. 2022GDASZH-2022010107), the National Key Research and Development Program of China (grant no. 2018YFA0703001), and the Key Research and Development of Guangdong Province (grant no. 2020B090923002).

Author information

Authors and Affiliations

Contributions

All persons who have made substantial contributions to the work reported in the manuscript, including those who provided editing and writing assistance but who are not authors, are named in the Acknowledgements section of the manuscript and have given their written permission to be named.

All authors contributed to the study conception and design as follows:

Yonghao Luo: conceptualization, validation, resources, data curation, writing — original draft, writing — review and editing, visualization, supervision, project administration, funding acquisition. Weiwen Sun: software, formal analysis, investigation, data curation, writing — original draft. Minle Bao: software, writing — review and editing, supervision. Xiaowu Zhu: writing — review and editing, supervision. Chenhong Ning: validation, formal analysis. Weiye Zhang: software, investigation. Yanhui Li: resources, funding acquisition. Xinyue Zhang: project administration, funding acquisition.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Luo, Y., Sun, W., Bao, M. et al. Process fundamentals and quality investigation in extrusion 3D printing of shear thinning materials: extrusion process based on Nishihara model. Int J Adv Manuf Technol 124, 245–264 (2023). https://doi.org/10.1007/s00170-022-10506-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10506-7