Abstract

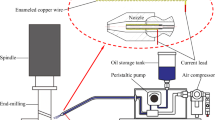

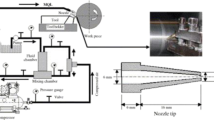

As an effective alternative to traditional pouring lubrication method, minimum quantity lubrication (MQL) has been recognized by more and more scholars and applied in factories. However, there are still some technical shortcomings in the application of traditional oil-based MQL technology, such as poor cooling capacity and low lubrication efficiency. Aiming at the technical defects of oil-based MQL, a magnetic field–assisted minimum quantity lubrication (mMQL) technology using Fe3O4 nanofluid as cutting fluid was proposed. First, MQL equipment with controllable magnetic field was built, and the contact angle, surface tension, and dynamic viscosity of Fe3O4 nanofluid droplets were measured under different magnetic induction intensities. Based on these variation parameters of physical properties of the magnetic nanofluid droplets, the influence of magnetic induction on the droplet penetrability was subsequently analyzed. Finally, the heat transfer performance and machining characteristics of the nanofluid droplets under different magnetic inductions were compared and investigated. Results showed that the Fe3O4 nanofluid droplets exhibited lower contact angle and higher viscosity under the influence of magnetic field, thus showing better penetrability and heat transfer performance. Compared with traditional vegetable oil MQL, the cutting temperature, tool wear, and cutting force under mMQL were reduced by ~ 35.5%, ~ 52.4%, and ~ 43.2%, respectively. Under the influence of magnetic field, the contact angle of magnetic droplets was decreased, and the contact area between the droplets and heat transfer surface was larger, which led to the improvement of droplet evaporation heat transfer efficiency. In addition, the penetrability of Fe3O4 nanofluid assisted by magnetic field was improved, more nanofluid could penetrate into the tool–chip contact area, and finally improved its lubrication and cooling efficiency.

Similar content being viewed by others

Data availability

All the experimental data and materials are reflected in this article.

References

Chinchanikar S, Kore SS, Hujare P (2021) A review on nanofluids in minimum quantity lubrication machining. J Manuf Process 68(A):56–70. https://doi.org/10.1016/j.jmapro.2021.05.028

Airao J, Nirala CK, Bertolini R, Krolczyk GM, Khanna N (2022) Sustainable cooling strategies to reduce tool wear, power consumption and surface roughness during ultrasonic assisted turning of Ti-6Al-4V. Tribol Int 169:107494. https://doi.org/10.1016/j.triboint.2022.107494

Zan ZL, Guo K, Sun J, Wei X, Tan YC, Yang B (2021) Investigation of MQL parameters in milling of titanium alloy. Int J Adv Manuf Tech 116(1–2):375–388. https://doi.org/10.1007/s00170-021-07441-4

Tamang SK, Chandrasekaran M, Sahoo AK (2018) Sustainable machining: an experimental investigation and optimization of machining Inconel 825 with dry and MQL approach. J Braz Soc Mech Sci 40(8):374. https://doi.org/10.1007/s40430-018-1294-2

Babu MN, Anandan V, Muthukrishnan N, Santhanakumar M (2019) End milling of AISI 304 steel using minimum quantity lubrication. Measurement 138:681–689. https://doi.org/10.1016/j.measurement.2019.01.064

Benjamin DM, Sabarish VN, Hariharan MV, Raj DS (2018) On the benefits of sub-zero air supplemented minimum quantity lubrication systems: an experimental and mechanistic investigation on end milling of Ti-6-Al-4-V alloy. Tribol Int 119:464–473. https://doi.org/10.1016/j.triboint.2017.11.021

Sarikaya M, Gupta MK, Tomaz I, Danish M, Mia M, Rubaiee S, Jamil M, Pimenov DY, Khanna N (2021) Cooling techniques to improve the machinability and sustainability of light-weight alloys: a state-of-the-art review. J Manuf Process 62:179–201. https://doi.org/10.1016/j.jmapro.2020.12.013

Leppert T (2012) Surface layer properties of AISI 316L steel when turning under dry and with minimum quantity lubrication conditions. Proc Inst Mech Eng J Eng Manuf 226(4):617–631. https://doi.org/10.1177/0954405411429894

Huang SQ, Lv T, Wang MH, Xu XF (2018) Effects of machining and oil mist parameters on electrostatic minimum quantity lubrication–EMQL turning process. Int J Pr Eng Man-GT 5(2):317–326. https://doi.org/10.1007/s40684-018-0034-5

Yuan SM, Han WL, Zhu GY, Hou XB, Wang L (2019) Recent progress on the efficiency increasing methods of minimum quantity lubrication technology in green cutting. J Mech Eng-EN 55(5):175–185. https://doi.org/10.3901/JME.2019.05.175

Jamil M, He N, Gupta MK, Zhao W, Khan AM (2022) Tool wear mechanisms and its influence on machining tribology of face milled titanium alloy under sustainable hybrid lubri-cooling. Tribol Int 170:107497. https://doi.org/10.1016/j.triboint.2022.107497

Khan AM, Anwar S, Alfaify A, Jamil M, Sharma S, Farooq MU, Khaliq W, Iqbal A (2022) Comparison of machinability and economic aspects in turning of Haynes-25 alloy under novel hybrid cryogenic-LN oils-on-water approach. Int J Adv Manuf Tech 120(1–2):427–445. https://doi.org/10.1007/s00170-022-08815-y

Xu XF, Lv T, Luan ZQ, Zhao YY, Wang MH, Hu XD (2019) Capillary penetration mechanism and oil mist concentration of Al2O3 nanoparticle fluids in electrostatic minimum quantity lubrication (EMQL) milling. Int J Adv Manuf Tech 104(5–8):1937–1951. https://doi.org/10.1007/s00170-019-04023-3

Liu MZ, Li CH, Zhang YB, An QL, Yang M, Gao T, Mao C, Liu B, Cao HJ, Xu XF, Said Z, Debnath S, Jamil M, Ali HM, Sharmal S (2021) Cryogenic minimum quantity lubrication machining: from mechanism to application. Front Mech Eng 16(4):649–697. https://doi.org/10.1007/s11465-021-0654-2

Morshed A, Wu H, Jiang ZY (2021) A comprehensive review of water-based nanolubricants. Lubricants 9(9):89. https://doi.org/10.3390/lubricants9090089

Huang W, Shen C, Liao SJ, Wang XL (2011) Study on the ferrofluid lubrication with an external magnetic field. Tribol Let 41(1):145–151. https://doi.org/10.1007/s11249-010-9693-2

Wang LJ, Guo CW, Ryuichiro Y, Yue W (2009) Tribological properties of Mn–Zn–Fe magnetic fluids under magnetic field. Tribol Int 42(6):792–797. https://doi.org/10.1016/j.triboint.2008.10.009

Ren Z, Zhou JF, Meng XN, Ling H (2019) Study on adaptive control method of mechanical seal hydrodynamically lubricated by magnetic fluid. Lubr Eng 44(2):45–50. https://doi.org/10.3969/j.issn.0254-0150.2019.02.008

Gao SQ, Liu HP (2010) Capillary mechanics. Science Press, Beijing

Zhu BY, Zhao GX (1981) The determination of the surface tension of a liquid: drop volume method. Chemistry 6:21–26

Lee BB, Ravindra P, Chan ES (2009) New drop weight analysis for surface tension determination of liquids. Colloid Surf A 332(2–3):112–120. https://doi.org/10.1016/j.colsurfa.2008.09.003

Huang SQ, Li ZY, Yao WQ, Hu JD, Xu XF (2014) Tribological performance of charged vegetable lubricants. Tribology 34(4):371–378. https://doi.org/10.16078/j.tribology.2014.04.002

Godlevski VA, Volkov AV, Latyshev VN, Maurin LN (2010) The kinetics of lubricant penetration action during machining. Lubr Sci 9(2):127–140

Young T (1805) An essay on the cohesion of fluids. Philos Trans R Soc Lond 95:65–87

Liu LS, Ren WJ, Tian L, Liu XC, Duan RZ (2021) Numerical simulation of spreading of droplet on wall and heat transfer process. Refrigeration 49(1):45–52. https://doi.org/10.16711/j.1001-7100.2021.01.008

Wang B, Liu ZQ, Su GS, Ai X (2015) Brittle removal mechanism of ductile materials with ultrahigh-speed machining. J Manuf Sci E-T Asme 137(6):061002. https://doi.org/10.1115/1.4030826

Zhao YZ, Li JF, Guo K, Sivalingam V, Sun J (2020) Study on chip formation characteristics in turning NiTi shape memory alloys. J Manuf Process 58:787–795. https://doi.org/10.1016/j.jmapro.2020.08.072

Funding

This study was financially supported by General Scientific Research Projects of Zhejiang Provincial Department of Education (project no. Y202043602), Ningbo Natural Science Foundation (project no. 202003N4190), National Natural Science Foundation of China (project no. 52275468), National Scientific Research Cultivation Project of Ningbo Polytechnic (NZ22GJ003).

Author information

Authors and Affiliations

Contributions

Conceptualization: TL, XX. Methodology: TL, HW. Original draft writing: TL, CN. Investigation: TL, HW. Review: XX, AY, XH. Language editing: TL, AY. Supervision: TL, XX. Financial support: TL, XX.

Corresponding author

Ethics declarations

Consent for publication

All authors agree to publish.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lv, T., Xu, X., Weng, H. et al. A study on lubrication and cooling performance and machining characteristics of magnetic field–assisted minimum quantity lubrication using Fe3O4 nanofluid as cutting fluid. Int J Adv Manuf Technol 123, 3857–3869 (2022). https://doi.org/10.1007/s00170-022-10500-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10500-z