Abstract

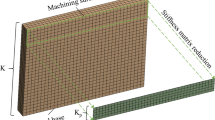

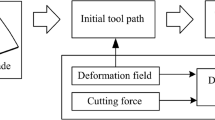

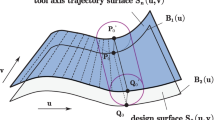

In order to reduce the machining deformation of thin-walled parts during milling, a non-uniform allowance planning method for thin-walled parts based on the workpiece deformation constraint with the idea of adding materials in reverse material removal sequence is proposed in this paper. This method does not require accurate deformation prediction and extensive experiments compared to traditional error compensation methods. It strives to maximize the allowance to enhance the stiffness of the in-process workpiece. First, a cutting force threshold calculation method is proposed according to the finite element method. The cutting force threshold at different positions is calculated by obtaining the local stiffness characteristics at the cutter-contact point under the constraint of allowable deformation. And then, the maximum machining allowance at the cutter-contact point is calculated depending on the cutting force model. Considering that the stiffness of the workpiece is position-dependent and affected by material removal, the stiffness of the workpiece is updated by adding elements in the reverse cutting direction, and the finishing stock is obtained by surface fitting. Experimental results show that compared with the traditional uniform allowance method, the error of the proposed method is reduced by about 83%, which can effectively reduce the deformation and improve the machining accuracy.

Similar content being viewed by others

References

Bera TC, Desai KA, Rao PVM (2011) Error compensation in flexible end milling of tubular geometries. J Mater Process Tech 211:24–34. https://doi.org/10.1016/j.jmatprotec.2010.08.013

Wang H, Huang LJ, Yao C, Kou M, Wang WY, Huang BH, Zheng WZ (2015) Integrated analysis method of thin-walled turbine blade precise machining. Int J Precis Eng Man 16:1011–1019. https://doi.org/10.1007/s12541-015-0131-0

Smith S, Wilhelm R, Dutterer B, Cherukuri H, Goel G (2012) Sacrificial structure preforms for thin part machining. Cirp Ann Manuf Technol 61:379–382. https://doi.org/10.1016/j.cirp.2012.03.142

Ferry WB, Altintas Y (2008) Virtual five-axis flank milling of jet engine impellers - part II: feed rate optimization of five-axis flank milling. J Manuf Sci E-T Asme 130. https://doi.org/10.1115/1.2815340

Altintas Y, Tuysuz O, Habibi M, Li ZL (2018) Virtual compensation of deflection errors in ball end milling of flexible blades. CIRP Ann 67:365–368. https://doi.org/10.1016/j.cirp.2018.03.001

Altintas Y, Kersting P, Biermann D, Budak E, Denkena B, Lazoglu I (2014) Virtual process systems for part machining operations. CIRP Ann 63:585–605. https://doi.org/10.1016/j.cirp.2014.05.007

Wan M, Zhang WH, Qiu KP, Gao T, Yang YH (2005) Numerical prediction of static form errors in peripheral milling of thin-walled workpieces with irregular meshes. J Manuf Sci E-T Asme 127:13–22. https://doi.org/10.1115/1.1828055

Li ZL, Tuysuz O, Zhu LM, Altintas Y (2018) Surface form error prediction in five-axis flank milling of thin-walled parts. Int J Mach Tools Manuf 128:21–32. https://doi.org/10.1016/j.ijmachtools.2018.01.005

Li ZL, Zhu LM (2019) Compensation of deformation errors in five-axis flank milling of thin-walled parts via tool path optimization. Precis Eng J Int Soc Precis Eng Nanotechnol 55:77–87. https://doi.org/10.1016/j.precisioneng.2018.08.010

Si H, Wang L (2019) Error compensation in the five-axis flank milling of thin-walled workpieces. Proc Inst Mech Eng Part B-J Eng Manuf 233:1224–1234. https://doi.org/10.1177/0954405418780163

Wang XZ, Li ZL, Bi QZ, Zhu LM, Ding H (2019) An accelerated convergence approach for real-time deformation compensation in large thin-walled parts machining. Int J Mach Tool Manuf 142:98–106. https://doi.org/10.1016/j.ijmachtools.2018.12.004

Koike Y, Matsubara A, Nishiwaki S, Izui K, Yamaji I (2012) Cutting path design to minimize workpiece displacement at cutting point: milling of thin-walled parts. Int J Automation Technol 6:638–647. https://doi.org/10.20965/ijat.2012.p0638

Koike Y, Matsubara A, Yamaji I (2013) Design method of material removal process for minimizing workpiece displacement at cutting point. CIRP Ann 62:419–422. https://doi.org/10.1016/j.cirp.2013.03.144

Wang J, Ibaraki S, Matsubara A (2017) A cutting sequence optimization algorithm to reduce the workpiece deformation in thin-wall machining. Precis Eng J Int Soc Precis Eng Nanotechnol 50:506–514. https://doi.org/10.1016/j.precisioneng.2017.07.006

Ma JW, He GZ, Liu Z, Qin FZ, Chen SY, Zhao XX (2018) Instantaneous cutting-amount planning for machining deformation homogenization based on position-dependent rigidity of thin-walled surface parts. J Manuf Process 34:401–411. https://doi.org/10.1016/j.jmapro.2018.05.027

Tian WJ, Ren JX, Wang DZ, Zhang BG (2018) Optimization of non-uniform allowance process of thin-walled parts based on eigenvalue sensitivity. Int J Adv Manuf Technol 96:2101–2116. https://doi.org/10.1007/s00170-018-1740-4

Tunc LT, Zatarain M (2019) Stability optimal selection of stock shape and tool axis in finishing of thin-wall parts. CIRP Ann 68:401–404. https://doi.org/10.1016/j.cirp.2019.04.096

Wu Y, Wang K, Zheng G, Lv B, He Y (2020) Experimental and simulation study on chatter stability region of integral impeller with non-uniform allowance. Sci Prog 103:36850420933418. https://doi.org/10.1177/0036850420933418

Shan CW, Zhao Y, Liu WW, Zhang DH (2013) A nonuniform offset surface rigidity compensation strategy in numerical controlled machining of thin-walled cantilever blades. Acta Aeronautica et Astronautica Sinica 34(03):686–693. https://doi.org/10.7527/S1000-6893.2013.0107

Chen YZ, Chen WF, Liang RJ, Feng T (2017) Machining allowance optimal distribution of thin-walled structure based on deformation control. Appl Mech Mater 868:158–165. https://doi.org/10.4028/www.scientific.net/AMM.868.158

Yan Q, Luo M, Tang K (2018) Multi-axis variable depth-of-cut machining of thin-walled workpieces based on the workpiece deflection constraint. Comput Aided Des 100:14–29. https://doi.org/10.1016/j.cad.2018.02.007

Hou Y, Zhang D, Zhang Y, Wu B (2021) The variable radial depth of cut in finishing machining of thin-walled blade based on the stable-state deformation field. Int J Adv Manuf Technol 113:141–158. https://doi.org/10.1007/s00170-020-06472-7

Xi X, Cai Y, Wang H, Zhao D (2022) A prediction model of the cutting force–induced deformation while considering the removed material impact. Int J Adv Manuf Technol 119:1579–1594. https://doi.org/10.1007/s00170-021-08291-w

Altintas Y (2012) Manufacturing Automation. Cambridge University Press, Cambridge, pp 4–65. https://doi.org/10.1017/CBO9780511843723

Budak E, Altintas Y, Armarego EJA (1996) Prediction of milling force coefficients from orthogonal cutting data. J Manuf Sci E-T Asme 118:216–224. https://doi.org/10.1115/1.2831014

Funding

This work is supported by grants from the National Natural Science Foundation of China (52005030) and the Industry-University-Research Collaboration project of China (HFZL2020CXY014-1).

Author information

Authors and Affiliations

Contributions

Zhengzhong Zhang proposed the method and carried out the experimental verification and result analysis. She also drafted the manuscript. Yonglin Cai discussed the study conception and experimental scheme. Xiaolin Xi contributed to the implementation of the algorithm. Yonglin Cai, Xiaolin Xi, and Haitong Wang commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The authors declare that this manuscript was not submitted to more than one journal for simultaneous consideration. The submitted work is original and has not been published elsewhere in any form or language.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Z., Cai, Y., Xi, X. et al. Non-uniform machining allowance planning method of thin-walled parts based on the workpiece deformation constraint. Int J Adv Manuf Technol 124, 2185–2198 (2023). https://doi.org/10.1007/s00170-022-10480-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10480-0