Abstract

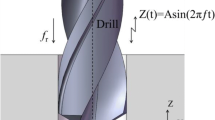

Vibration-assisted drilling is a process in which vibrations with a specific amplitude and frequency are applied to the cutting tool or workpiece during drilling. These vibrations lead to an intermittent contact between the tool and the workpiece, which results in breaking the chips, reduction of temperature, reduction of machining forces, improvement of surface quality, and increase of tool life. In this study, a low-frequency vibration-assisted drilling device is designed and fabricated. This device is then used to perform drilling experiments on high-density polyethylene (HDPE) workpieces. The developed tool is connected to a drilling machine and creates axial vibrations with an amplitude of 0.25 mm and a frequency of 5 oscillations per revolution in the cutting tool. Effects of the process on chip morphology and surface roughness are investigated and compared with conventional drilling. The results show that using the developed tool leads to formation of short broken chips. Machined surface roughness is also shown to be reduced by 29.6 to 52.9% compared to conventional drilling. Regression analysis is performed to model and predict surface roughness based on the input parameters, which include rotational speed and feed rate. Analysis of variance is then performed to find the most significant parameters and the effect of each parameter on surface roughness. Finally, the optimal parameters to achieve the minimum surface roughness are calculated using both response surface and genetic algorithm methods.

Similar content being viewed by others

References

Rivero A, Aramendi G, Herranz SB, López de Lacalle LN (2006) An experimental investigation of the effect of coatings and cutting parameters on the dry drilling performance of aluminium alloys. Int J Adv Manuf Technol 28:1–11

Azarhoushang B, Akbari J (2007) Ultrasonic-assisted drilling of Inconel 738-LC. Int J Mach Tools Manuf 47(7):1027–1033. https://doi.org/10.1016/j.ijmachtools.2006.10.007

Chu N-H, Nguyen V-D, Do T-V (2018) Ultrasonic-assisted cutting: a beneficial application for temperature, torque reduction, and cutting ability improvement in deep drilling of Al-6061. Applied Sciences 8 (10). https://doi.org/10.3390/app8101708

Hussein R, Sadek A, Elbestawi MA, Attia MH (2018) Low-frequency vibration-assisted drilling of hybrid CFRP/Ti6Al4V stacked material. Int J Adv Manuf Technol 98(9):2801–2817. https://doi.org/10.1007/s00170-018-2410-2

Sanda A, Arriola I, Garcia Navas V, Bengoetxea I, Gonzalo O (2016) Ultrasonically assisted drilling of carbon fibre reinforced plastics and Ti6Al4V. J Manuf Process 22:169–176. https://doi.org/10.1016/j.jmapro.2016.03.003

Zhang LB, Wang LJ, Liu XY, Zhao HW, Wang X, Luo HY (2001) Mechanical model for predicting thrust and torque in vibration drilling fibre-reinforced composite materials. Int J Mach Tools Manuf 41(5):641–657. https://doi.org/10.1016/S0890-6955(00)00105-X

Chang SSF, Bone GM (2009) Thrust force model for vibration-assisted drilling of aluminum 6061–T6. Int J Mach Tools Manuf 49(14):1070–1076. https://doi.org/10.1016/j.ijmachtools.2009.07.011

Amini S, Soleimani M, Paktinat H, Lotfi M (2017) Effect of longitudinal−torsional vibration in ultrasonic-assisted drilling. Mater Manuf Processes 32(6):616–622. https://doi.org/10.1080/10426914.2016.1198027

Feng Y, Wang H, Zhang M, Zhu Z, Wang X, Jia B, Jia X (2020) Experimental research on hole wall integrity of TiBw/TC4 based on ultrasonic vibration assisted drilling. Int J Precis Eng Manuf 21(5):915–926. https://doi.org/10.1007/s12541-019-00308-5

Wang Y, Cao M, Zhao X, Zhu G, McClean C, Zhao Y, Fan Y (2014) Experimental investigations and finite element simulation of cutting heat in vibrational and conventional drilling of cortical bone. Med Eng Phys 36(11):1408–1415. https://doi.org/10.1016/j.medengphy.2014.04.007

Singh G, Jain V, Gupta D, Sharma A (2018) Parametric effect of vibrational drilling on osteonecrosis and comparative histopathology study with conventional drilling of cortical bone. Proc Inst Mech Eng [H] 232(10):975–986. https://doi.org/10.1177/0954411918794983

Jiao F, Li Y, Wang D, Tong J, Niu Y (2021) Development of a low-frequency vibration-assisted drilling device for difficult-to-cut materials

Veiga F, Suárez A, Val AGD, Penalva M, Lacalle LNLD (2020) Evaluation on advantages of low frequency assisted drilling (LFAD) aluminium alloy Al7075. International Journal of Mechatronics and Manufacturing Systems 13(3):230–246. https://doi.org/10.1504/IJMMS.2020.111283

Chen J, An Q, Zou F, Yu D, Chen M (2021) Analysis of low-frequency vibration-assisted bone drilling in reducing thermal injury. Mater Manuf Processes 36(1):27–38. https://doi.org/10.1080/10426914.2020.1813891

Thoe TB, Aspinwall DK, Wise MLH (1998) Review on ultrasonic machining. Int J Mach Tools Manuf 38(4):239–255. https://doi.org/10.1016/S0890-6955(97)00036-9

Liu D, Tang Y, Cong WL (2012) A review of mechanical drilling for composite laminates. Compos Struct 94(4):1265–1279. https://doi.org/10.1016/j.compstruct.2011.11.024

Deyuan Z, Lijiang W (1998) Investigation of chip in vibration drilling. Int J Mach Tools Manuf 38(3):165–176. https://doi.org/10.1016/S0890-6955(97)00047-3

Amran M, Salmah S, Hussein N, Izamshah R, Hadzley M, Kasim M, Sulaiman M (2013) Effects of machine parameters on surface roughness using response surface method in drilling process. Procedia Engineering 68:24–29

Cicek A, Kıvak T, Samtaş G (2012) Application of Taguchi method for surface roughness and roundness error in drilling of AISI 316 stainless steel, Strojniški vestnik. J Mech Eng 58(3):165–174

Palanikumar K (2010) Modeling and analysis of delamination factor and surface roughness in drilling GFRP composites. Mater Manuf Process 25(10):1059–1067

Zhang JZ, Chen JC (2009) Surface roughness optimization in a drilling operation using the Taguchi design method. Mater Manuf Process 24(4):459–467

Funding

The research of the corresponding author is supported by a grant from Ferdowsi University of Mashhad (N.3/54272).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception, design, material preparation, data collection, and analysis. The first draft of the manuscript was written by Amirhossein Erfani, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Erfani, A., Ghandehariun, A. & Afsharfard, A. Experimental investigation and optimization of low-frequency vibration-assisted drilling. Int J Adv Manuf Technol 123, 3171–3182 (2022). https://doi.org/10.1007/s00170-022-10438-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10438-2