Abstract

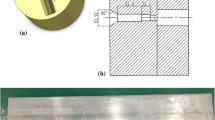

The forming properties of AZ31 magnesium alloy plates were obtained by tensile tests, using Autoform software to simulate the room-temperature stamping process of AZ31 magnesium alloy. And orthogonal experiments were explored on the variable-curvature plate shell parts of AZ31 magnesium alloy in order to investigate the influence of various forming parameters. The conditions of 14.41% sufficient forming with blank-holder force, clearance between punch and die, the resistance coefficient of drawbead, and the coefficient of friction were clarified. The results suggest that the blank-holder force plays a preponderant role in the maximum thinning rate of the room-temperature stamping formability of AZ31. Additionally, the study found that the curvature of the punch radius is negatively associated with the average thinning rate. In order to promote the flow of metal around the punch radius and to improve the forming uniformity and ultimate forming depth, it is necessary to reduce the curvature of the punch radius to reduce the stress concentration at the punch radius.

Similar content being viewed by others

References

Mordike BL, Ebert T (2001) Magnesium: properties — applications — potential. Mater Sci Eng, A 302:37–45. https://doi.org/10.1016/S0921-5093(00)01351-4

Jia W, Ma L, Jiao M, Le Q, Han T, Che C (2020) Fracture criterion for predicting edge-cracking in hot rolling of twin-roll casted AZ31 Mg alloy. J Market Res 9:4773–4787. https://doi.org/10.1016/j.jmrt.2020.02.103

Che B, Lu L, Zhang J, Zhang J, Ma M, Wang L, Qi F (2022) Effects of cryogenic treatment on microstructure and mechanical properties of AZ31 magnesium alloy rolled at different paths. Mater Sci Eng, A 832:142475. https://doi.org/10.1016/j.msea.2021.142475

Jia W, Ma L, Le Q, Zhi C, Liu P (2019) Deformation and fracture behaviors of AZ31B Mg alloy at elevated temperature under uniaxial compression. J Alloy Compd 783:863–876. https://doi.org/10.1016/j.jallcom.2018.12.260

Friedrich H, Schumann S (2001) Research for a “new age of magnesium” in the automotive industry. J Mater Process Technol 117:276–281. https://doi.org/10.1016/S0924-0136(01)00780-4

Chen F-K, Huang T-B (2003) Formability of stamping magnesium-alloy AZ31 sheets. J Mater Process Technol 142:643–647. https://doi.org/10.1016/S0924-0136(03)00684-8

Alaneme KK, Okotete EA (2017) Enhancing plastic deformability of Mg and its alloys—a review of traditional and nascent developments. J Magnes Alloys 5:460–475. https://doi.org/10.1016/j.jma.2017.11.001

Sułkowski B, Janoska M, Boczkal G, Chulist R, Mroczkowski M, Pałka P (2020) The effect of severe plastic deformation on the Mg properties after CEC deformation. J Magnes Alloys 8:761–768. https://doi.org/10.1016/j.jma.2020.04.005

Song B, Guo N, Liu T, Yang Q (2014) Improvement of formability and mechanical properties of magnesium alloys via pre-twinning: a review. Mater Des 1980–2015 62:352–360. https://doi.org/10.1016/j.matdes.2014.05.034

Watanabe H, Mukai T, Ishikawa K (2004) Differential speed rolling of an AZ31 magnesium alloy and the resulting mechanical properties. J Mater Sci 39:1477–1480. https://doi.org/10.1023/B:JMSC.0000013922.16079.d3

Huang G, Zhang L, Song B, Pan F (2010) Cold stamping for AZ31B magnesium alloy sheet of cell phone house. Trans Nonferrous Metals Soc China 20:s608–s612. https://doi.org/10.1016/S1003-6326(10)60548-1

Zhang H, Ren S, Li X, Wang L, Fan J, Chen S, Zhu L, Meng F, Tong Y, Roven HJ, Zhang S, Jiang L (2020) Dramatically enhanced stamping formability of Mg–3Al–1Zn alloy by weakening (0001) basal texture. J Mater Res Technol 9:14742–14753. https://doi.org/10.1016/j.jmrt.2020.10.041

Mori K, Nishijima S, Tan CJ (2009) Two-stage cold stamping of magnesium alloy cups having small corner radius. Int J Mach Tools Manuf 49:767–772. https://doi.org/10.1016/j.ijmachtools.2009.04.005

Zhao R, Jia W, Ma L, Ning F, Xie H, Yuan Y (2022) Transverse microstructural evolution and its cellular automata simulation during hot rolling of AZ31 alloy wide-width plate. Mater Today Commun 32:104097. https://doi.org/10.1016/j.mtcomm.2022.104097

Jia W, Wang L, Ma L, Li H, Xie H, Yuan Y (2022) Deformation failure behavior and fracture model of twin-roll casting AZ31 alloy under multiaxial stress state. J Market Res 17:2047–2058. https://doi.org/10.1016/j.jmrt.2022.01.067

Song J, She J, Chen D, Pan F (2020) Latest research advances on magnesium and magnesium alloys worldwide. J Magnes Alloys 8:1–41. https://doi.org/10.1016/j.jma.2020.02.003

Yi S, Bohlen J, Heinemann F, Letzig D (2010) Mechanical anisotropy and deep drawing behaviour of AZ31 and ZE10 magnesium alloy sheets. Acta Mater 58:592–605. https://doi.org/10.1016/j.actamat.2009.09.038

Funding

This work was supported by the National Natural Science Foundation of China (U1910213 and 52105388) and the Key Research and Development Program of Shanxi Province (No. 202102050201005).

Author information

Authors and Affiliations

Contributions

All the authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Hengtao Wang, Weitao Jia, and Lifeng Ma. The first draft of the manuscript was written by Hengtao Wang, and all the authors commented on the previous versions of the manuscript. All the authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, H., Ma, L., Jia, W. et al. Analysis of room-temperature stamping formability of complex features of AZ31 magnesium alloy variable-curvature plate shell. Int J Adv Manuf Technol 123, 3159–3169 (2022). https://doi.org/10.1007/s00170-022-10412-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10412-y