Abstract

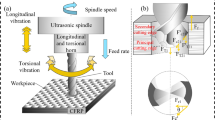

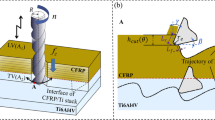

Carbon fiber–reinforced plastics (CFRP)/titanium alloy (Ti) stacks are extensively applied in the aerospace industry due to their excellent mechanical properties. However, their poor machinability poses great challenges. In this study, longitudinal-torsional ultrasonic vibration drilling (LT-UVD) is innovatively introduced to improve the quality of CFRP/Ti drilling. First, the separation mode of LT-UVD is analyzed by kinematic equations. Then, an experimental platform is built based on the LT-UVD vibration actuator to perform CFRP/Ti drilling experiments. The thrust force, interface temperature, hole wall quality, hole defects, Ti chip morphologies, and tool wear in LT-UVD are experimentally compared against conventional drilling (CD) and longitudinal ultrasonic vibration drilling (L-UVD). The experimental results show that, compared with CD and L-UVD, the thrust force of CFRP in LT-UVD decreases by 20.36–40.55% and 2.04–14.61%, while the thrust force of Ti decreases by 19.08–24.83% and 1.95–9.34%. Moreover, a relatively low maximum interface temperature is achieved in LT-UVD. In addition, the hole size accuracy, surface roughness for the hole’s inner surface, and delamination factor are improved in LT-UVD. Fiber pullout defects, chip-breaking performance, and tool wear of CFRP are improved due to torsional vibration in LT-UVD. Finally, according to the high-speed camera, damage forms of the interface area are different when drilling CFRP/Ti stacks with various drilling sequences.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are not publicly available, but are available from the corresponding author on reasonable request.

Code availability

The code that supports the findings of this study is available from the corresponding author upon request.

References

Wang B, Wang Y, Zhao H, Lei S, Wang M, Kong X (2020) Effect of a Ti alloy layer on CFRP hole quality during helical milling of CFRP/Ti laminate. Compos struct 252:112670. https://doi.org/10.1016/j.compstruct.2020.112670

Kumar D, Gururaja S, Jawahir IS (2020) Machinability and surface integrity of adhesively bonded Ti/CFRP/Ti hybrid composite laminates under dry and cryogenic conditions. J Manuf Process 58:1075–1087. https://doi.org/10.1016/j.jmapro.2020.08.064

Jia Z, Zhang C, Wang F, Fu R, Chen C (2019) An investigation of the effects of step drill geometry on drilling induced delamination and burr of Ti/CFRP stacks. Compos struct 235:111786. https://doi.org/10.1016/j.compstruct.2019.111786

Wang Q, Wang F, Zhang C, Chen C (2020) Combined effects of various materials on tool wear in drilling of Ti/CFRP stacks. P I Mech Eng C-J Mec 234(14):2750–2759. https://doi.org/10.1177/0954406219868246

Suo H, Wei Z, Zhang K, Deng K, Cheng H, Luo B, Li H, Wang L, Liang B (2022) Interfacial wear damage of CFRP/Ti-alloy single-lap bolted joint after long-term seawater aging. Eng Fail Anal 139:106464. https://doi.org/10.1016/j.engfailanal.2022.106464

Kolesnyk V, Peterka J, Alekseev O, Neshta A, Xu J, Lysenko B, Sahul M, Martinovič J, Hrbal J (2022) Application of ANN for analysis of hole accuracy and drilling temperature when drilling CFRP/Ti alloy stacks. Materials 15(5):1940. https://doi.org/10.3390/ma15051940

Zhang Z, Zhang N, Wu F, Teng W, Sun Y, Guo B (2022) Research on variable parameter drilling method of Ti-CFRP-Ti laminated stacks based on real-time sensing of drilling axial force. Sensors 22(3):1188. https://doi.org/10.3390/s22031188

An Q, Zhong B, Wang X, Zhang H, Sun X, Chen M (2021) Effects of drilling strategies for CFRP/Ti stacks on static mechanical property and fatigue behavior of open-hole CFRP laminates. J Manuf Process 64:409–420. https://doi.org/10.1016/j.jmapro.2021.01.036

Fernández-Pérez J, Cantero JL, Díaz-Álvarez J, Miguélez MH (2017) Influence of cutting parameters on tool wear and hole quality in composite aerospace components drilling. Compos struct 178:157–161. https://doi.org/10.1016/j.compstruct.2017.06.043

Luo B, Zhang K, Liu S, Cheng H, Wang R (2019) Investigation on the interface damage in drilling low-stiffness CFRP/Ti stacks. Chinese J Aeronaut 32(9):2211–2221. https://doi.org/10.1016/j.cja.2019.04.017

Samsudeensadham S, Krishnaraj V (2022) Drilling study on CFRP/Ti-6Al-4V stacks using chip breaker grooved drill. Mater Manuf Process 37(13):1511–1525. https://doi.org/10.1080/10426914.2022.2030872

Jia Z, Zhang C, Wang F, Fu R, Chen C (2020) Multi-margin drill structure for improving hole quality and dimensional consistency in drilling Ti/CFRP stacks. J Mater Process Tech 276:116405. https://doi.org/10.1016/j.jmatprotec.2019.116405

Alonso U, Calamaz M, Girot F, Iriondo E (2019) Influence of flute number and stepped bit geometry when drilling CFRP/Ti6Al4V stacks. J Manuf Process 39:356–370. https://doi.org/10.1016/j.jmapro.2019.02.006

Qiu X, Yu Z, Li C, Niu Q, Li S, Li P, Ko TJ (2021) Influence of main cutting edge structure on hole defects in CFRP/titanium alloy stacks drilling. J Manuf Process 69:503–513. https://doi.org/10.1016/j.jmapro.2021.07.061

Shao Z, Jiang X, Li Z, Geng D, Li S, Zhang D (2019) Feasibility study on ultrasonic-assisted drilling of CFRP/Ti stacks by single-shot under dry condition. Int J Adv Manuf Tech 105(1–4):1259–1273. https://doi.org/10.1007/s00170-019-04329-2

Shao Z, Jiang X, Geng D, Liu Y, Zhou Z, Li S, Zhang D, Zheng W (2021) The interface temperature and its influence on surface integrity in ultrasonic-assisted drilling of CFRP/Ti stacks. Compos struct 226:113803. https://doi.org/10.1016/j.compstruct.2021.113803

Dahnel AN, Barnes S, Ascroft H, Gloger M (2015) Analysis of tool wear and hole quality during ultrasonic assisted drilling (UAD) of carbon fibre composite (CFC)/titanium alloy (Ti6Al4V) stacks. ASME Int Mech Eng Congress Expo. https://doi.org/10.1115/IMECE2015-50416.IMECE2015-50416

Liu Y, Li Q, Qi Z, Chen W (2021) Defect suppression mechanism and experimental study on longitudinal torsional coupled rotary ultrasonic assisted drilling of CFRPs. J Manuf Process 70:177–192. https://doi.org/10.1016/j.jmapro.2021.08.042

Ma G, Kang R, Dong Z, Yin S, Bao Y, Guo D (2020) Hole quality in longitudinal–torsional coupled ultrasonic vibration assisted drilling of carbon fiber reinforced plastics. Front Mech Eng-Prc 15:(538–546). https://doi.org/10.1007/s11465-020-0598-y

Wang X, Jiao F, Wang D, Niu Y (2019) Development of a longitudinal–torsional ultrasonic vibration-aided drilling system for drilling carbon fiber-reinforced polymer materials. P I Mech Eng C-J Mec 233(12):4176–4186. https://doi.org/10.1177/0954406219833084

Liu Y, Pan Z, Li Q, Qi Z, Chen W (2022) Experimental and scale-span numerical investigations in conventional and longitudinal torsional coupled rotary ultrasonic–assisted drilling of CFRPs. Int J Adv Manuf Tech 199(3–4):1707–1724. https://doi.org/10.1007/s00170-021-08286-7

Tian Y, Zou P, Kang D, Fan F (2021) Study on tool wear in longitudinal-torsional composite ultrasonic vibration–assisted drilling of Ti-6Al-4V alloy. Int J Adv Manuf Tech 113(7–8):1989–2002. https://doi.org/10.1007/s00170-021-06759-3

Gao G, Xia Z, Yuan Z, Xiang D, Zhao B (2021) Influence of longitudinal-torsional ultrasonic-assisted vibration on micro-hole drilling Ti-6Al-4V. Chinese J Aeronaut 34(9):247–260. https://doi.org/10.1016/j.cja.2020.06.012

Xu J, Ji M, Paulo Davim J, Chen M, El Mansori M, Krishnaraje V (2020) Comparative study of minimum quantity lubrication and dry drilling of CFRP/titanium stacks using TiAlN and diamond coated drills. Compos Struct 234:111727. https://doi.org/10.1016/j.compstruct.2019.111727

An Q, Dang J, Li J, Wang C, Chen M (2020) Investigation on the cutting responses of CFRP/Ti stacks: With special emphasis on the effects of drilling sequences. Compos Struct 253:112794. https://doi.org/10.1016/j.compstruct.2020.112794

Xu J, El Mansori M (2016) Experimental study on drilling mechanisms and strategies of hybrid CFRP/Ti stacks. Compos Struct 157:461–482. https://doi.org/10.1016/j.compstruct.2016.07.025

Geng D, Zhang D, Li Z, Liu D (2017) Feasibility study of ultrasonic elliptical vibration-assisted reaming of carbon fiber reinforced plastics/titanium alloy stacks. Ultrasonics 75:80–90. https://doi.org/10.1016/j.ultras.2016.11.011

Funding

This research was funded by the National Natural Science Foundation of China (No. 51775260, No. 52205471), the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (21KJB460022), and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (No. SJCX21_0942).

Author information

Authors and Affiliations

Contributions

All authors contributed to the experiments, data, and manuscript of the study.

Corresponding author

Ethics declarations

Ethics approval

Written informed consent was obtained from all the participants prior to the enrollment (or for the publication) of this study.

Consent to participate

The authors agreed to participate in the submission.

Consent for publication

The authors approved the final manuscript and the submission to this journal.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, Z., Feng, Y., Xu, W. et al. Experimental study on longitudinal-torsional ultrasonic vibration drilling of carbon fiber–reinforced plastics/titanium alloy stacks. Int J Adv Manuf Technol 124, 527–543 (2023). https://doi.org/10.1007/s00170-022-10409-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10409-7