Abstract

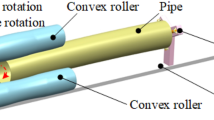

Aiming at the low efficiency and unstable accuracy of the current mold-pressing straightening for LSAW pipes, a three-roll continuous straightening process is proposed in this study, which uses the roller straightening instead of mold bending. According to the novel technology, the calculation model of the theoretical straightening moment is derived based on the springback equation of plane bending with small curvature, and the calculation model of initial curvature is established for the new deflection detection method. Furthermore, the numerical simulation analysis is carried out for the LSAW pipe case, and a straightening experimental platform is built for experiments. The research shows that the accuracy of the theoretical moment equation required for straightening is directly related to the initial curvature, rather than the fitting accuracy of the deflection curve, and the low-order simple-fitting curvature calculation model has the highest reliability. In order to control the section distortion and the straightening blind area, the straightening roller should follow the equal diameter design principle, and the empirical formula of span estimation is given. Under the optimal conditions, the straightness of the corrected tubes can be controlled within 1.5‰ and the ovality of the section can be within 0.5%, which proves the feasibility and reliability of the new process. What’s more, the straightening system built in this work, including process analysis software, is conducive to the automation and popularization of the new process.

Similar content being viewed by others

References

(2012) ANSI/API Specification 5L, Specification for line pipe, 45th edn. Washington DC, US

Zhai H, Zhong HY, Zhao H (2010) Research on crankshaft straightening NP-hard problem based on weighted evaluation function. In: 2010 2nd International Conference on Information Engineering and Computer Science. IEEE, Wuhan, China. https://doi.org/10.1109/ICIECS.2010.5678407

Pei YC, Wang JW, Tan QC, Yuan DZ, Zhang F (2017) An investigation on the bending straightening process of D-type cross section shaft. Int J Mech Sci 131–132:1082–1091. https://doi.org/10.1016/j.ijmecsci.2017.08.032

Zhao J, Song XK, Cao HQ, Liu J (2014) Press straightening control strategy of multi-step three-point bending for LSAW pipes. J Harbin Inst Technol 46(1):90–96. https://doi.org/10.11918/j.issn.0367-6234.2014.01.016

Zhao J, Song XK, Cao HQ, Liu J (2014) Principle of multi-point bending one-off straightening process for longitudinally submerged arc welding pipes. Chin J Mech Eng 50(2):92–97. https://doi.org/10.3901/JME.2014.02.092

Ma WZ, Shen HY, Xu GH (2022) Study on cracks and process improvement for case hardened gear shaft straightening. J Mech Sci Technol 36(6):2861–2870. https://doi.org/10.1007/s12206-022-0518-7

Cui F, Yang HL (2015) New understanding in the field of straightening theory. Heavy Mach 43(1):83–84. https://doi.org/10.13551/j.cnki.zxjxqk.2015.01.001

Yu GC, Zhao J, Ma R, Zhai RX (2016) Uniform curvature theorem by reciprocating bending and its experimental verification. J Mechanical Eng 52(18):57–63. https://doi.org/10.3901/JME.2016.18.057

Yin J, Zhao J, Wang S, Li Y (2014) Multiroller straightening analytical model of H-beam. Ironmak Steelmak 41(7):521–528. https://doi.org/10.1179/1743281213Y.0000000149

Jindřich P, Tomáš N, František Š (2016) Novel approach to computational simulation of cross roll straightening of bars. J Mater Process Technol 233:53–67. https://doi.org/10.1016/j.jmatprotec.2016.02.004

Wang CG, Zhang ZY, Zhai RX, Yu GC, Zhao J (2018) Cross-sectional distortion of LSAW pipes in over-bend straightening process. Thin-Walled Struct 129(AUG):85–93. https://doi.org/10.1016/j.tws.2018.03.016

Ma R, Wang CG, Zhai RX, Zhao J (2019) An iterative compensation algorithm for springback control in plane deformation and its application. Chin J Mech Eng 32(2):212–223. https://doi.org/10.1186/s10033-019-0339-5

Mu ZK, Ma R, Zhao J, Yu GC, Sun HL (2021) Research on iterative compensation method for springback control based on implicit equation. Int J Mater Form 14:1097–1108. https://doi.org/10.1007/s12289-021-01625-9

Yu GC, Zhai RX, Zhao J, Ma R (2018) Theoretical analysis and numerical simulation on the process mechanism of two-roller straightening. Int J Adv Manuf Technol 9(9–12):4011–4021. https://doi.org/10.1007/s00170-017-1120-5

Ma LF, Ma ZY, Jia WT, Lv YY, Jiang YP, Xu HJ, Liu PT (2015) Research and verification on neutral layer offset of bar in two-roll straightening process. Int J Adv Manuf Technol 79(9–12):1519–1529. https://doi.org/10.1007/s00170-015-6899-3

Ma ZY, Ma LF, Wang RJ, Huang QX, Ma LD (2017) Study on control strategies of two-roll straightening for bar high precision straightening. J Mechanical Eng 53(20):77–88. https://doi.org/10.3901/JME.2017.20.077

Huang XY, Yu GC, Zhai RX, Ma R, Zhou C, Gao CL, Zhao J (2021) Roller design and numerical simulation of three-roller continuous and synchronous adjusting straightness and roundness process on LSAW pipes. J Mechanical Eng 57(10):148–159. https://doi.org/10.3901/JME.2021.10.148

Huang XY, Yu GC, Sun HL, Zhao J (2021) A mechanical model of axial and circumferential bidirectional deformation for large thin-walled pipes in the process of continuous and synchronous calibration of roundness and straightness by three rollers. Int J Adv Manuf Technol 116(11/12):3809–3826. https://doi.org/10.1007/s00170-021-07479-4

Huang XY, Yu GC, Wang CG, Zhao J (2022) Deformation mechanism analysis of three-roller continuous and synchronous calibration process of straightness and roundness for LSAW pipes. Int J Adv Manuf Technol 121:1731–1742. https://doi.org/10.1007/s00170-022-09426-3

Ma R, Zhao J, Meng XC (2012) Key technology of deflection detecting system for large longitudinal welding pipe. Forging & Stamping Technol 37(5):126–128. https://doi.org/10.3969/j.issn.1000-3940.2012.05.031

Zhao J, Wang CG, Zhai RX (2016) A three-roll continuous straightening device and process method for LSAW pipes. Hebei: CN201610053710, 2016–01–27.

Wang CG, Yu GC, Wang W, Zhao J (2018) Deflection detection and curve fitting in three-roll continuous straightening process for LSAW pipes. J Mater Process Technol 255:150–160. https://doi.org/10.1016/j.jmatprotec.2017.11.060

Zhao J, Yin J, Ma R (2011) Springback equation of small curvature plane bending. Sci China Technol Sci 54(9):2386–2396 (DOI:CNKI:SUN:JEXG.0.2011-09-023)

Zhou LQ (2001) Shaft straightening and straightening load calculation. Machinery Design & Manufacture 6:54–55. https://doi.org/10.3969/j.issn.1001-3997.2001.06.024

Liu LX (2006) Study on the straightening load model of shaft part. Jilin University Press, Changchun

Ma HW (2009) The reach on quantitative calculation method of pivot distance of pressure straightening. East China Jiaotong University Press, Nanchang

Wang LY, Zhang GY, Xu XP (2009) Theoretical analysis on the error of three coordinate measuring system based on the leapfrog type. J Mechanical Eng 54(4):304–308. https://doi.org/10.3901/JME.2009.04.304

Zhao J, Cao HQ, Zhan PP, Ma R (2012) Pure bending equivalent principle for over-bend straightening and its experimental verification. J Mechanical Eng 48(8):28–33. https://doi.org/10.3901/JME.2012.08.028

Acknowledgements

The authors would like to thank the National Natural Science Foundation of China, National Natural Science Foundation of Hebei province for their financial support, and the Ningbo key research and development plan in 2022.

Funding

This project was funded and supported by the National Natural Science Foundation of China (grant number 52005431), the National Natural Science Foundation of Hebei province (grant number E2020203086), and the Ningbo key research and development plan in 2022 (grant number 2022Z057).

Author information

Authors and Affiliations

Contributions

Chunge Wang: conceptualization, methodology, validation, formal analysis, investigation, data curation, writing—original draft, writing—review and editing, software, visualization; Keke Zhang: conceptualization, methodology, formal analysis, supervision, writing—review and editing; Ning Zhang: conceptualization, methodology, formal analysis, supervision, writing—review and editing; Rongzhi Li: conceptualization, methodology, formal analysis, supervision; Bangbang Ma: conceptualization, methodology, formal analysis, supervision; Gaochao Yu: conceptualization, methodology, formal analysis, supervision; Jun Zhao: conceptualization, methodology, formal analysis, supervision; Xueying Huang: conceptualization, methodology, formal analysis, supervision.

Corresponding author

Ethics declarations

Ethical approval and consent to participate

The authors declare that this manuscript was not submitted to more than one journal for simultaneous consideration. Also, the submitted work is original and not have been published elsewhere in any form or language. The authors declare that they participated in this paper willingly.

Consent for publication

The authors declare to consent to the publication of this paper.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, C., Zhang, K., Zhang, N. et al. A systematic study on three-roll continuous straightening process for LSAW pipes. Int J Adv Manuf Technol 124, 165–182 (2023). https://doi.org/10.1007/s00170-022-10397-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10397-8