Abstract

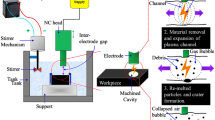

Wire electrochemical machining (WECM) is a transport-limited dissolving process. The application of various wire electrode coating and insulation methods and the effect of various prominent parameters for reduction of stray current attack and overcut play a more important role in the enhancement of machining accuracy, homogeneity, and surface quality during the fabrication of microfeatures. Therefore, the characteristics of the stray-current attack in WECM were identified through simulation for electrolyte potential, and current density distribution at narrow IEG in the machining zone and overcut model is presented in this paper. Also, the use of synthetic enamel and novel PTFE (polytetrafluoroethylene) tube insulation method was used to reduce the stray current effect and overcut during WECM, and a comparative study has been made with uncoated wire. The stray-current attack and overcut have been greatly reduced by the proposed insulating methods under different parametric conditions. The PTFE pipe tube wire insulation method is proved to be the most prominent method with no stray current attack on fabricated microslits. Also, overcut is reduced to a large extent which is below 5 µm, and a microslit of 100.61 µm average slit width has been fabricated using PTFE tube insulation method with 180° exposed wire angle and 100 µm insulation distance from workpiece upper surface at 40 µm initial interelectrode gap. Further, NiTinol shape memory alloy microslit array was fabricated and analyzed based on SEM and EDX analysis for understanding the effect of PTFE tube wire insulation method during WECM.

Similar content being viewed by others

References

Munda J, Malapati M, Bhattacharyya B (2007) Control of micro-spark and stray-current effect during EMM process. J Mater Process Technol 151–158:194. https://doi.org/10.1016/j.jmatprotec.2007.04.112

Swain AK, Sundaram MM, Rajurkar KP (2012) Use of coated micro tools in advanced manufacturing: an exploratory study in electrochemical machining (ECM) context. J Manuf Process 14:150–159. https://doi.org/10.1016/j.jmapro.2011.11.005

Fang X, Qu N, Li H, Zhu D (2013) Enhancement of insulation coating durability in electrochemical drilling. Int J Adv Manuf Technol 68:2005–2013. https://doi.org/10.1007/s00170-013-4803-6

Wang D, Zhu Z, Zhu D, He B, Ge Y (2017) Reduction of stray currents in counter-rotating electrochemical machining by using a flexible auxiliary electrode mechanism. J Mater Process Technol 239:66–74. https://doi.org/10.1016/j.jmatprotec.2016.08.008

Tyagi A, Sharma V, Patel DS, Jain VK, Ramkumar J (2019) Experimental and analytical investigations into wire electrochemical micro turning, J. Micromanufacturing. https://doi.org/10.1177/2516598419827130

Liu G, Tong H, Li Y, Zhong H (2021) Novel structure of a sidewall-insulated hollow electrode for micro electrochemical machining. Precis Eng 72:356–369. https://doi.org/10.1016/j.precisioneng.2021.05.009

Shin HS, Kim BH, Chu CN (2008) Analysis of the side gap resulting from micro electrochemical machining with a tungsten wire and ultra short voltage pulses. J Micromech Micro engineering 18:075009. https://doi.org/10.1088/0960-1317/18/7/075009

Wang S, Zhu D, Zeng Y, Liu Y (2011) Micro wire-electrode electrochemical cutting with low frequency and small amplitude tool vibration. Int J Adv Manuf Technol 535–544:53. https://doi.org/10.1007/s00170-010-2835-8

Zeng YB, Yu Q, Wang S, Zhu D (2012) Enhancement of mass transport in micro wire electrochemical machining. CIRP Ann Manuf Technol 195–198:61. https://doi.org/10.1016/j.cirp.2012.03.082

Volgin VM, Do VD, Davydov AD (2014) Modeling of wire electrochemical machining. Chemical engineering transactions 41. https://doi.org/10.1016/j.procir.2015.08.098

Tyagi A, Sharma V, Jain VK, Ramkumar J (2017) Investigations into side gap in wire electrochemical micromachining (wire-ECMM). Int. J. Adv. Manuf. Technol. 1–10. https://doi.org/10.1007/s00170-017-1150-z

Debnath S, Kundu J, Bhattacharyya B (2017) Influence of high duty ratio and frequency in WECM employing in situ fabricated wire electrode. J Micro-and Nano-Manufact Transact ASME 5:041005-1–41009. https://doi.org/10.1115/1.4037768

He H, Zeng Y, Yao Y, Ningsong Q (2017) Improving machining efficiency in wire electrochemical micromachining of array microstructures using axial vibration-assisted multi-wire electrodes. J Manuf Process 25:452–460. https://doi.org/10.1016/j.jmapro.2017.01.004

He H, Zhang X, Qu N, Zeng Y, Zhong B (2019) Wire electrochemical micromachining assisted with coupling axial and intermittent feed-direction vibrations. J Electrochem Soc 166(6):E165–E180. https://doi.org/10.1149/2.1001906jes

Bi X, Zeng Y (2020) Revealing the instantaneous machining gap produced during wire electrochemical micromachining using electrochemical deposition. Int J Electrochemical. Sci 15(11080):11091. https://doi.org/10.20964/2020.11.20

Patel DS, Sharma V, Jain VK, Ramkumar J (2020) Reducing overcut in electrochemical micromachining process by altering the energy of voltage pulse using sinusoidal and triangular waveform. Int J Mach Tools Manuf 151:103526. https://doi.org/10.1016/j.ijmachtools.2020.103526

Sharma V, Patel DS, Jain VK, Ramkumar J (2020) Wire electrochemical micromachining: an overview. International Journal of Machine Tools and Manufacture, 155- 103579. https://doi.org/10.1016/j.ijmachtools.2020.103579

Zhou Z, Fang X, Zeng Y, Zhu D (2021) Research on machining gap distribution in wire electrochemical micromachining. Journal of the Electrochemical Society, 168- 043503. https://doi.org/10.1149/1945-7111/abf79c

Besekar N, Bhattacharyya B (2021) Vibration-assisted axial nozzle jet flow wire electrochemical machining for micromachining. J Micro-and Nano-Manufact Transact ASME 9:044501–044507. https://doi.org/10.1115/1.4053747

Besekar N, Bhattacharyya B (2022) Experimental investigation and characterization of NiTinol shape memory alloy during wire electrochemical machining. J Manuf Process 81:346–361. https://doi.org/10.1016/j.jmapro.2022.07.019

Funding

This research work has been conducted under the financial assistantship of the Science and Engineering Research Board, DST (grant no. SB/S3/MMER/0056/2014), New Delhi, India.

Author information

Authors and Affiliations

Contributions

Naresh Besekar contributed to the study conception and design, simulation, material preparation, experiments, data recording, and the writing of the first draft of the manuscript. B. Bhattacharyya contributed to the overall evaluation and revised the paper. All the listed authors have confirmed the final version of the manuscript and approved it for submission.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Besekar, N., Bhattacharyya, B. Wire electrode insulation method for stray current and overcut reduction during WECM—a novel approach. Int J Adv Manuf Technol 123, 3917–3942 (2022). https://doi.org/10.1007/s00170-022-10381-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10381-2