Abstract

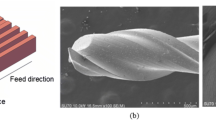

Aluminum alloys specifically Al6061 have widespread applications; however, its processing is challenging via conventional means due to chip adhesion and burr formation. Moreover, it is difficult to attain dimensional accuracy of the machined profile in the said alloy especially if the size of the machined profile is in a micron which is a common requirement in case of microchannels’ formation. Microchannels have wide applications in biomedical, chemical, and electronics industry. Therefore, in this study, the potential of EDM is comprehensively investigated for machining of dimensionally consistent microchannel(s) in Al6061. Single, double, and triple microchannel(s) are produced using laminated brass electrode(s) employing Taguchi (L18) design. The dimensional error was measured for each of the produced microchannel(s) using coordinate measuring machine (CMM). It has been revealed that number of channels and electrode thickness is the significant factors contributing 84.9% and 4.7%, respectively, to the depth deviation (Dd). Dd increases with increase in number of channels and electrode thickness. Electrode thickness is the most influential parameter (85.4%) affecting width deviation of microchannel(s). Width deviation experiences, a drop when a thicker electrode is engaged. The thinnest electrode (0.2 mm) has provided the highest value of arc radius which translates to flatter base of channel.

Similar content being viewed by others

References

Verma S, Rao PS (2018) Study on mechanical behavior of aluminum alloy 6061 based composites a review. IOSR J Mech Civ Eng 15:16–20. https://doi.org/10.9790/1684-1504031620 (e-ISSN)

Yoo SC, Kang B, Van Trinh P, Phuong DD, Hong SH (2020) Enhanced mechanical and wear properties of Al6061 alloy nanocomposite reinforced by CNT-template-grown core–shell CNT/SiC nanotubes. Sci Rep 10:12896. https://doi.org/10.1038/s41598-020-69341-z

Duan Z, Ma H, He B, Su L, Zhang X (2019) Pressure drop of microchannel plate fin heat sinks. Micromachines 10:80. https://doi.org/10.3390/mi10020080

Chaides O, Ahuett-Garza H, Castro JM (2016) Determination of process parameters for microchannel fabrication by microelectro-discharge machining. Proc Inst Mech Eng Part B J Eng Manuf 230:1702–1714. https://doi.org/10.1177/0954405414567520

Prakash S, Kumar S (2015) Fabrication of microchannels: a review. Proc Inst Mech Eng Part B J Eng Manuf 229:1273–1288. https://doi.org/10.1177/0954405414535581

Vinoth R, Senthil Kumar D (2018) Experimental investigation on heat transfer characteristics of an oblique finned microchannel heat sink with different channel cross sections. Heat Mass Transf 54:3809–3817. https://doi.org/10.1007/s00231-018-2398-z

Prakash S, Kumar S (2015) Fabrication of microchannels on transparent PMMA using CO2 Laser (10.6 μm) for microfluidic applications: an experimental investigation. Int J Precis Eng Manuf 16:361–366. https://doi.org/10.1007/s12541-015-0047-8

Sahu AK, Jha S (2020) Microchannel fabrication and metallurgical characterization on titanium by nanosecond fiber laser micromilling. Mater Manuf Process 35:279–290. https://doi.org/10.1080/10426914.2020.1718702

Ahmed N, Darwish S, Alahmari AM (2016) Laser ablation and laser-hybrid ablation processes: a review. Mater Manuf Process 31:1121–1142. https://doi.org/10.1080/10426914.2015.1048359

Khan Malek CG (2006) Laser processing for bio-microfluidics applications (part II). Anal Bioanal Chem 385:1362–1369. https://doi.org/10.1007/s00216-006-0517-z

Sahu AK, Malhotra J, Jha S (2022) Laser-based hybrid micromachining processes: a review. Opt Laser Technol 146:107554. https://doi.org/10.1016/j.optlastec.2021.107554

Ishfaq K, Asad M, Anwar S, Pruncu CI, Saleh M, Ahmad S (2020) A comprehensive analysis of the effect of graphene-based dielectric for sustainable electric discharge machining of Ti-6Al-4V. Materials (Basel) 14:23. https://doi.org/10.3390/ma14010023

Kumar SV, Kumar MP (2014) Optimization of cryogenic cooled EDM process parameters using grey relational analysis. J Mech Sci Technol 28:3777–3784. https://doi.org/10.1007/s12206-014-0840-9

Jain S, Parashar V (2021) Critical review on the impact of EDM process on biomedical materials. Mater Manuf Process 36:1701–1724. https://doi.org/10.1080/10426914.2021.1942907

Banu A, Ali MY (2016) Electrical discharge machining (EDM): a review. Int J Eng Mater Manuf 1:3–10. https://doi.org/10.26776/ijemm.01.01.2016.02

Nahak B, Gupta A (2019) A review on optimization of machining performances and recent developments in electro discharge machining. Manuf Rev 6:2. https://doi.org/10.1051/mfreview/2018015

Schubert A, Zeidler H, Kühn R, Hackert-Oschätzchen M (2015) Microelectrical discharge machining: a suitable process for machining ceramics. J Ceram 2015:1–9. https://doi.org/10.1155/2015/470801

Phipon R, Shivakoti I, Sharma A (2020) Sustainable processing of Inconel 718 super alloy in electrical discharge machining process. World J Eng 17:687–695. https://doi.org/10.1108/WJE-03-2020-0077

Gholipoor A, Baseri H, Shabgard MR (2015) Investigation of near dry EDM compared with wet and dry EDM processes. J Mech Sci Technol 29:2213–2218. https://doi.org/10.1007/s12206-015-0441-2

Bilal A, Jahan M, Talamona D, Perveen A (2018) Electro-Discharge machining of ceramics: a review. Micromachines 10:10. https://doi.org/10.3390/mi10010010

Gostimirovic M, Kovac P, Sekulic M, Skoric B (2012) Influence of discharge energy on machining characteristics in EDM. J Mech Sci Technol 26:173–179. https://doi.org/10.1007/s12206-011-0922-x

Singh AK, Mahajan R, Tiwari A, Kumar D, Ghadai RK (2018) Effect of Dielectric on electrical discharge machining: a review. IOP Conf Ser Mater Sci Eng 377:012184. https://doi.org/10.1088/1757-899X/377/1/012184

Shelke RD, Imran SM (2019) A review-electrical discharge machining. 16:34–39. https://doi.org/10.9790/1684-1601023439

Tuckerman DB, Pease RFW (1981) High-performance heat sinking for VLSI. IEEE Electron Device Lett 2:126–129. https://doi.org/10.1109/EDL.1981.25367

Kwon B, Maniscalco NI, Jacobi AM, King WP (2018) High power density air-cooled microchannel heat exchanger. Int J Heat Mass Transf 118:1276–1283. https://doi.org/10.1016/j.ijheatmasstransfer.2017.11.068

Yeom T, Simon T, Zhang M, Yu Y, Cui T (2018) Active heat sink with piezoelectric translational agitators, piezoelectric synthetic jets, and micro pin fin arrays. Exp Therm Fluid Sci 99:190–199. https://doi.org/10.1016/j.expthermflusci.2018.07.035

Deng D, Chen X, Chen L, Lian Y, Fu T (2019) Preparation of porous structures on copper microchannel surfaces by laser writing. Sci China Technol Sci 62:2261–2270. https://doi.org/10.1007/s11431-018-9430-9

Hakamada M, Asao Y, Kuromura T, Chen Y, Kusuda H, Mabuchi M (2007) Fabrication of copper microchannels by the spacer method. Scr Mater 56:781–783. https://doi.org/10.1016/j.scriptamat.2007.01.014

Zhao D, Zhang Z, Zhu H, Cao Z, Xu K (2020) An investigation into laser-assisted electrochemical discharge machining of transparent insulating hard-brittle material. Micromachines 12:22. https://doi.org/10.3390/mi12010022

Gudipudi S, Nagamuthu S, Subbian KS, Chilakalapalli SPR (2020) Experimental investigation and mathematical modeling for material removal and tool wear in making of rectangular channels by electric discharge machining (EDM) on aluminum–boron carbide composite sintered preform. Advances in applied mechanical engineering. Springer, Singapore, pp 1011–1019

Pozdniakov AV, Lotfy A, Qadir A, Shalaby E, Khomutov MG, Churyumov AY, Zolotorevskiy VS (2017) Development of Al-5Cu/B4C composites with low coefficient of thermal expansion for automotive application. Mater Sci Eng A 688:1–8. https://doi.org/10.1016/j.msea.2017.01.075

Cem Okumus S, Aslan S, Karslioglu R, Gultekin D, Akbulut H (2012) Thermal expansion and thermal conductivity behaviors of Al-Si/SiC/graphite hybrid metal matrix composites (MMCs). Mater Sci 18. https://doi.org/10.5755/j01.ms.18.4.3093

Gudipudi S, Selvaraj N, Chandra D, Kanmani Subbu S, Rao C (2020) A study on geometrical features of electric discharge machined channels on AA6061-4%B 4 C composites. Meas Control 53:358–377. https://doi.org/10.1177/0020294019888241

Wang W, Liu Y, Zhang W, Ma F, Yang D, Zhang S (2019) Research on shape change of multimaterial electrode for EDM. Adv Mater Sci Eng 2019:1–11. https://doi.org/10.1155/2019/9159835

Jiang K, Wu X, Lei J, Hu Z, Gao G, Tang Y, Diao D (2021) Investigation on the geometric evolution of microstructures in EDM with a composite laminated electrode. J Clean Prod 298:126765. https://doi.org/10.1016/j.jclepro.2021.126765

Trych-Wildner A, Wildner K (2017) Multifilament carbon fibre tool electrodes in micro EDM—evaluation of process performance based on influence of input parameters. Int J Adv Manuf Technol 91:3737–3747. https://doi.org/10.1007/s00170-017-0041-7

Chuvaree S, Kanlayasiri K (2018) Improving the performance of EDM deep hole using multi-hole interior flushing electrode. IOP Conf Ser Mater Sci Eng 361:012013. https://doi.org/10.1088/1757-899X/361/1/012013

Yang X, Yang K, Liu Y, Wang L (2016) Study on characteristic of multi-spark EDM method by using capacity coupling. Procedia CIRP 42:40–45. https://doi.org/10.1016/j.procir.2016.02.182

Singh M, Garg H, Maharana S, Yadav A, Singh R, Maharana P, Nguyen T, Yadav S, Loganathan M (2021) An Experimental investigation on the material removal rate and surface roughness of a hybrid aluminum metal matrix composite (Al6061/SiC/Gr). Metals (Basel) 11:1449. https://doi.org/10.3390/met11091449

Rahman M, Wong YS, Nguyen MD (2014) Compound and hybrid micromachining. Comprehensive materials processing. Elsevier, Singapore, pp 113–150

Yilmaz Atay H, Uslu G, Kahmaz Y, Atay Ö (2020) Investigations of microstructure and mechanical properties of brass alloys produced by sand casting method at different casting temperatures. IOP Conf Ser Mater Sci Eng 726:012018. https://doi.org/10.1088/1757-899X/726/1/012018

Rashedul IM, Zhang Y, Zhou K, Wang G, Xi T, Ji L (2021) Influence of different tool electrode materials on electrochemical discharge machining performances. Micromachines 12:1077. https://doi.org/10.3390/mi12091077

Bolboacă S, Jäntschi L (2007) Design of experiments: useful orthogonal arrays for number of experiments from 4 to 16. Entropy 9:198–232. https://doi.org/10.3390/e9040198

Rehman M, Khan SA, Naveed R (2020) Parametric optimization in electric wire discharge machining of DC53 steel using gamma phase coated wire. J Mech Sci Technol 34:1–7. https://doi.org/10.1007/s12206-020-05

Lei J, Wu X, Zhou Z, Xu B, Zhu L, Tang Y (2021) Sustainable mass production of blind multi-microgrooves by EDM with a long-laminated electrode. J Clean Prod 279:123492. https://doi.org/10.1016/j.jclepro.2020.123492

Sabur A, Ali MY, Maleque MA, Moudood MA (2014) Micro-EDM for Micro-channel fabrication on nonconductive ZrO2 ceramic. Int J Automot Mech Eng 10:1841–1851. https://doi.org/10.15282/ijame.10.2014.2.0153

Ali MY, Rahman MA, Zuhaida Zunairi SN, Banu A (2017) Dimensional accuracy of micro-electro discharge milling. IOP Conf Ser Mater Sci Eng 184:012034. https://doi.org/10.1088/1757-899X/184/1/012034

Skoczypiec S, Machno M, Bizoń W (2015) The capabilities of electrodischarge microdrilling of high aspect ratio holes in ceramic materials. Manag Prod Eng Rev 6:61–69. https://doi.org/10.1515/mper-2015-0027

Xin B, Gao M, Li S, Feng B (2020) Modeling of interelectrode gap in electric discharge machining and minimum variance self-tuning control of interelectrode gap. Math Probl Eng 2020:1–20. https://doi.org/10.1155/2020/5652197

Bhaumik M, Maity K (2018) Effect of different tool materials during EDM performance of titanium grade 6 alloy. Eng Sci Technol Int J 21:507–516. https://doi.org/10.1016/j.jestch.2018.04.018

Jesudas T, Arunachalam RM (2011) Study on influence of process parameter in micro - electrical discharge machining (μ-EDM). Eur J Sci Res 59:115–122

Acknowledgements

Authors are thankful to the support provided by the University of Engineering and Technology, to assist in the completion of this research work.

Data assessment

All the concerned data have already been contained in the paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

Authors confirm that they have abided by the publication ethics, state that this work is original, and have not been used for publication anywhere before.

Consent for publication

Authors give consent to journal regarding the publication of this work.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ishfaq, K., Naveed, R., Maqsood, M.A. et al. Analyzing laminated electrode(s) performance for the EDM of microchannel(s) in Al(6061). Int J Adv Manuf Technol 123, 2941–2958 (2022). https://doi.org/10.1007/s00170-022-10360-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10360-7