Abstract

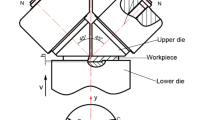

Double-roll rotary forging is an advanced partial progressive forming technology with multi-factor coupling interactive effects. To date, a few relevant researches on the double-roll rotary forging technology of large-diameter thin-walled discs have been reported, and the stable rolling conditions, stress field, velocity field, and so on are not studied in detail. Herein, a reasonable 3D rigid-plastic finite model of the double-roll hot rotary forging of a disk workpiece is established under the DEFORM software environment. Based on the valid 3D finite model, the distribution of stress field and velocity field and the influence of die preheating and initial size of workpiece on the uniformity and maximum axial load were studied. The research results can promote the application and development of rotary forging technology.

Similar content being viewed by others

Availability of data and materials

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

All software used in this article is licensed.

References

Davoudi M, Nejad AF, Rahimian Koloor SS, Petrů M (2021) Investigation of effective geometrical parameters on wear of hot forging die. J Market Res 15:5221–5231

Emamverdian AA, Sun Y, Chunping C (2021) Deformation and wear in a H21 (3Cr2W8V) steel die during hot forging: simulation, mechanical properties, and microstructural evolution. J Market Res 15:268–277

Suárez Fernández D, Wynne BP, Crawforth P, Fox K, Jackson M (2021) The effect of forging texture and machining parameters on the fatigue performance of titanium alloy disc components. Int J Fatigue 142:105949

Wei T, Dai X, Long C, Sun C, Long S, Zheng J, Wang P, Jia Y, Zhang J (2021) Comparison on the microstructure, aqueous corrosion behavior and hydrogen uptake of a new Zr-Sn-Nb alloy prepared by different hot rolling temperature. Corros Sci 192:109808

Li L, Xie H, Liu T, Huo M, Liu X, Li X, Shi K, Li J, Liu H, Sun L, Jiang Z (2022) Influence mechanism of rolling force on strip shape during tandem hot rolling using a novel 3D multi-stand coupled thermo-mechanical FE model. J Manuf Process 81:505–521

Yang Y, Jiang Z, Chen Y, Liu X, Sun J, Wang W (2022) Interfacial microstructure and strengthening mechanism of stainless steel/carbon steel laminated composite fabricated by liquid-solid bonding and hot rolling. Mater Charact 112122

Guan C, Chen G, Kai X, Cao R, Miao C, Xu Z, Zhao Y (2022) Evolution of microstructure and mechanical properties of graphene nanoplates and ZrB2 nanoparticles reinforced AA6111 composites during hot rolling deformation. J Alloy Compd 920:165910

Ganguly S, Wang X, Chandrashekhara K, Buchely MF, Lekakh S, O’Malley RJ, Kumar A, Thapliyal V (2021) Modeling and simulation of mass flow during hot rolling low carbon steel I-beam. J Manuf Process 64:285–293

Oudin J, Ravalard Y, Verwaerde G, Gelin JC (1985) Force, torque and plastic flow analysis in rotary upsetting of ring shaped billets. Int J Mech Sci 27:761–780

Canta T, Frunza D, Sabadus D, Tintelecan C (1998) Some aspects of energy distribution in rotary forming processes. J Mater Process Technol 80:195–198

Oh HK, Choi S (1997) A study on center thinning in the rotary forging of a circular plate. J Mater Process Technol 66:101–106

Zhou DC, Yuan SJ, Wang ZR, Xiao ZR (1992) Defects caused in forming process of rotary forged parts and their preventive methods. J Mater Process Technol 32:471–479

Decheng Z, Yadong H, Wang ZR (1992) Research on rotary forging and its distribution of deformation. J Mater Process Technol 31:161–168

Wang GC, Guan J, Zhao GQ (2005) A photo-plastic experimental study on deformation of rotary forging a ring workpiece. J Mater Process Technol 169:108–114

Yuan SJ, Wang XH, Liu G, Chou DC (1999) The precision forming of pin parts by cold-drawing and rotary-forging. J Mater Process Technol 86:252–256

Han XH, Hua L (2013) Effect of process parameters on wear in cold rotary forging by using 3D FE numerical simulation. Ironmak Steelmak 40:50–60

Han XH, Hua L (2013) 3D FE modelling of contact pressure response in cold rotary forging. Tribol Int 57:115–123

Han XH, Hua L (2012) Friction behaviors in cold rotary forging of 20CrMnTi alloy. Tribol Int 55:29–39

Han XH, Hua L (2011) Prediction of contact pressure, slip distance and wear in cold rotary forging using finite element methods. Tribol Int 44:1742–1753

Zheng Y, Liu D, Qiu S, Wang S, Wei L, Wang Z, Tian D (2019) Effect of deformation routes on torsion behavior via ACDR process. Int J Adv Manuf Technol 104:4105–4116

Zheng Y, Liu D, Yang Y, Zhang Z, Li X, Zhang R (2018) Microstructure evolution of Ti-6Al-4V with periodic thermal parameters during axial closed die rolling process. J Alloy Compd 735:996–1009

Zheng Y, Liu D, Yang YH, Ren LJ, Zhang Z, Gao GJ (2016) Investigation on metal flow during the hot axial closed die rolling process for titanium alloy discs. Int J Adv Manuf Technol 87:2445–2458

Zheng Y, Liu D, Zhang Z, Yang Y, Ren L (2017) The flow line evolution of hot open ACDR process for titanium alloy discs. Arch Civil Mech Eng 17:827–838

Han X, Hua L, Zhuang W, Zhang X (2014) Process design and control in cold rotary forging of non-rotary gear parts. J Mater Process Technol 214:2402–2416

Han X, Hua L, Zhou G, Lu B, Wang X (2014) A new cylindrical ring rolling technology for manufacturing thin-walled cylindrical ring. Int J Mech Sci 81:95–108

Han X, Hu Y, Hua L (2016) Cold orbital forging of gear rack. Int J Mech Sci 117:227–242

Yu Z, Zhu C, Chen M, Luo S (2022) Forming characteristics and mechanism of double-roll rotary forging for large-diameter and thin-walled metal discs. Int J Adv Manuf Technol 119:7543–7555

Shi L, Zhu C, Liu X, Zhang Y (2020) Optimum design of the double roll rotary forging machine frame. Mech Sci 11:101–114

Wang T (1988) Metal plastic processing: rolling theory and technology. Metall Ind Press

Hua L, Han X (2009) 3D FE modeling simulation of cold rotary forging of a cylinder workpiece. Mater Des 30:2133–2142

Funding

The authors were financially supported by the National Natural Science Foundation of China (No. 51875427).

Author information

Authors and Affiliations

Contributions

Zhongquan Yu and Chundong Zhu proposed the idea and performed the theoretical work. Zhongquan Yu completed the writing of the paper. Zhongquan Yu, Mingchao Chen, Chong Ma, and Site Luo performed the experimental work.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

We would like to declare that the work described has not been published previously, and not under consideration for publication elsewhere, in whole or in part.

Consent for publication

All the authors listed have approved the manuscript that is enclosed.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yu, Z., Zhu, C., Chen, M. et al. 3D FE modeling simulation of the double-roll hot rotary forging of large diameter thin-walled metal disk. Int J Adv Manuf Technol 123, 2123–2137 (2022). https://doi.org/10.1007/s00170-022-10278-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10278-0