Abstract

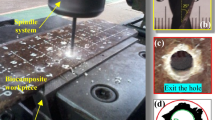

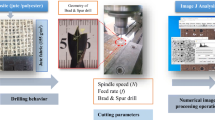

Polymeric biocomposites are emerging as a convenient alternative for traditional materials used in light-weight structural applications. Many studies on the machining of biocomposites were published in recent years. However, their number remains limited compared to the number of studies on the machining of glass and carbon fiber–reinforced composites. Therefore, drilling of Washingtonia filifera (WF) fiber-reinforced high-density polyethylene (HDPE) biocomposites was studied in this research by varying various factors, such as drill diameter (d), feed rate (f), and spindle speed (N) using full factorial design (L27). Response surface methodology (RSM) was applied for the drilling experiment and was used in conjunction with artificial neural network (ANN) in mathematical modeling of the drilling operation parameters. The results showed excellent agreement between experimental data and RSM/ANN predictions. Hence, the developed biocomposite HDPE/WF can be used in the polymer field to improve overall product performances. Furthermore, the drilling parameter optimization results obtained by the genetic algorithm (GA) combined with ANN are almost similar to those of the desirability function (DF) of RSM, especially f = 50 mm/min, N = 806 rev/min, and d = 5 mm.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Corbière-Nicollier T, Gfeller Laban B, Lundquist L, Leterrier Y, Månson J-A, Jolliet O (2001) Life cycle assessment of biofibres replacing glass fibres as reinforcement in plastics. Resour Conserv Recycl 33:267–287. https://doi.org/10.1016/S0921-3449(01)00089-1

de Brito J, Kurda R (2021) The past and future of sustainable concrete: a critical review and new strategies on cement-based materials. J Clean Prod 281:123558. https://doi.org/10.1016/j.jclepro.2020.123558

Bourmaud A, Beaugrand J, Shah DU, Placet V, Baley C (2018) Towards the design of high-performance plant fibre composites. Prog Mater Sci 97:347–408. https://doi.org/10.1016/j.pmatsci.2018.05.005

Sood M, Dwivedi G (2018) Effect of fiber treatment on flexural properties of natural fiber reinforced composites: a review. Egypt J Pet 27:775–783. https://doi.org/10.1016/j.ejpe.2017.11.005

Saaidia A, Belaadi A, Haddad A (2022) Moisture absorption of cork-based biosandwich material extracted from Quercussuber L. Plant: ANN and Fick’s Modelling. J Nat Fibers 1–18. https://doi.org/10.1080/15440478.2022.2072996

Belaadi A, Amroune S, Seki Y, Keskin OY, Köktaş S, Bourchak M, Dufresne A, Fouad H, Jawaid M (2022) Extraction and characterization of a new lignocellulosic fiber from Yucca Treculeana L. leaf as potential reinforcement for industrial biocomposites. J Nat Fibers 1–16. https://doi.org/10.1080/15440478.2022.2054895

Dembri I, Belaadi A, Boumaaza M, Bourchak M (2022) Tensile behavior and statistical analysis of Washingtonia filifera fibers as potential reinforcement for industrial polymer biocomposites. J Nat Fibers 1–16. https://doi.org/10.1080/15440478.2022.2069189

Benzannache N, Belaadi A, Boumaaza M, Bourchak M (2021) Improving the mechanical performance of biocomposite plaster/Washingtonian filifira fibres using the RSM method. J Build Eng. https://doi.org/10.1016/j.jobe.2020.101840

Makhlouf A, Belaadi A, Amroune S, Bourchak M, Satha H (2020) Elaboration and characterization of flax fiber reinforced high density polyethylene biocomposite: effect of the heating rate on thermo-mechanical properties. J Nat Fibers 1–14. https://doi.org/10.1080/15440478.2020.1848737

Cherief M, Belaadi A, Bouakba M, Bourchak M, Meddour I (2020) Behaviour of lignocellulosic fibre-reinforced cellular core under low-velocity impact loading: Taguchi method. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-020-05393-9

Cherief M, Belaadi A, Boumaaza M, Bourchak M (2021) The effect of geometry on the flexural properties of cellular structures reinforced with natural fibres: statistical approach. J Nat Fibers 1–15. https://doi.org/10.1080/15440478.2021.1964134

Boumaaza M, Belaadi A, Bourchak M (2022) Systematic review on reinforcing mortars with natural fibers: challenges of environment-friendly option. J Nat Fibers 1–25. https://doi.org/10.1080/15440478.2022.2060408

Vigneshwaran S, Sundarakannan R, John KM, Joel Johnson RD, Prasath KA, Ajith S, Arumugaprabu V, Uthayakumar M (2020) Recent advancement in the natural fiber polymer composites: a comprehensive review. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.124109

Abdul Kudus MH, Ratnam MM, Md Akil H (2022) Image processing method for delamination and fiber pull-out assessment during drilling of natural fiber composites. J Reinf Plast Compos. https://doi.org/10.1177/07316844211051734

Voss R, Seeholzer L, Kuster F, Wegener K (2017) Influence of fibre orientation, tool geometry and process parameters on surface quality in milling of CFRP. CIRP J Manuf Sci Technol. https://doi.org/10.1016/j.cirpj.2016.10.002

Feito N, Díaz-álvarez J, Díaz-álvarez A, Cantero JL, Miguélez MH (2014) Experimental analysis of the influence of drill point angle and wear on the drilling of woven CFRPs. Materials 7:4258–4271. https://doi.org/10.3390/ma7064258

Qiu X, Li P, Li C, Niu Q, Chen A, Ouyang P, Ko TJ (2018) Study on chisel edge drilling behavior and step drill structure on delamination in drilling CFRP. Compos Struct 203:404–413. https://doi.org/10.1016/j.compstruct.2018.07.007

Hocheng H, Chen CC, Tsao CC (2018) Prediction of critical thrust force for tubular composite in drilling-induced delamination by numerical and experimental analysis. Compos Struct. https://doi.org/10.1016/j.compstruct.2018.07.051

Davim JP, Reis P (2003) Drilling carbon fiber reinforced plastics manufactured by autoclave—experimental and statistical study. Mater Des 24:315–324. https://doi.org/10.1016/S0261-3069(03)00062-1

Jaafar MF, Salleh MS, Izamshah R, Hassan MH, Sundi SA, Hafiz MSA, Kasim MS (2019) Influence on thrust force and delamination for one shot drilling of carbon fibre reinforced plastic (CFRP). Int J Mech Mechatron Eng

Gaitonde VN, Karnik SR, Rubio JC, Correia AE, Abrão AM, Davim JP (2008) Analysis of parametric influence on delamination in high-speed drilling of carbon fiber reinforced plastic composites. J Mater Process Technol. https://doi.org/10.1016/j.jmatprotec.2007.10.050

Khashaba UA (2022) A novel approach for characterization of delamination and burr areas in drilling FRP composites. Compos Struct 290:115534. https://doi.org/10.1016/j.compstruct.2022.115534

Dembri I, Belaadi A, Boumaaza M, Alshahrani H, Bourchak M (2022) Drilling performance of short Washingtonia filifera fiber–reinforced epoxy biocomposites: RSM modeling. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-022-09849-y

Tsao CC, Hocheng H (2005) Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills. Int J Mach Tools Manuf. https://doi.org/10.1016/j.ijmachtools.2005.01.009

Abrão AM, Faria PE, Rubio JCC, Reis P, Davim JP (2007) Drilling of fiber reinforced plastics: a review. J Mater Process Technol 186:1–7. https://doi.org/10.1016/j.jmatprotec.2006.11.146

Giasin K, Ayvar-Soberanis S (2017) An Investigation of burrs, chip formation, hole size, circularity and delamination during drilling operation of GLARE using ANOVA. Compos Struct. https://doi.org/10.1016/j.compstruct.2016.10.015

Seif MA, Khashaba UA, Rojas-Oviedo R (2007) Measuring delamination in carbon/epoxy composites using a shadow moiré laser based imaging technique. Compos Struct. https://doi.org/10.1016/j.compstruct.2005.11.039

De Albuquerque VHC, Tavares JMRS, Durão LMP (2009) Evaluation of delamination damage on composite plates using an artificial neural network for the radiographic image analysis. J Compos Mater 44:1139–1159. https://doi.org/10.1177/0021998309351244

Greenhalgh ES, Canturri C, Katafiasz TJ (2021) Fractographic study into the effect of drilling damage on bearing mechanisms and performance in carbon-fibre epoxy composites. Eng Fail Anal. https://doi.org/10.1016/j.engfailanal.2021.105638

Silva D, Pamies Teixeira J, Machado CM (2014) Methodology analysis for evaluation of drilling-induced damage in composites. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-014-5616-y

Durão LMP, Tavares JMRS, de Albuquerque VHC, Gonçalves DJS (2013) Damage evaluation of drilled carbon/epoxy laminates based on area assessment methods. Compos Struct. https://doi.org/10.1016/j.compstruct.2012.08.003

Geier N, Póka G, Jacsó Á, Pereszlai C (2022) A method to predict drilling-induced burr occurrence in chopped carbon fibre reinforced polymer (CFRP) composites based on digital image processing. Compos Part B En 242:110054. https://doi.org/10.1016/j.compositesb.2022.110054

Zhang H, Zhu P, Liu Z, Qi S, Zhu Y (2020) Research on prediction method of mechanical properties of open-hole laminated plain woven CFRP composites considering drilling-induced delamination damage. Mech Adv Mater Struct 1–16. https://doi.org/10.1080/15376494.2020.1745969

Romoli L, Lutey AHA (2019) Quality monitoring and control for drilling of CFRP laminates. J Manuf Process. https://doi.org/10.1016/j.jmapro.2019.02.028

Davim JP, Rubio JC, Abrao AM (2007) A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos Sci Technol 67:1939–1945. https://doi.org/10.1016/j.compscitech.2006.10.009

Díaz-Álvarez A, Rodríguez-Millán M, Díaz-Álvarez J, Miguélez MH (2018) Experimental analysis of drilling induced damage in aramid composites. Compos Struct 202:1136–1144. https://doi.org/10.1016/j.compstruct.2018.05.068

Díaz-Álvarez A, Díaz-Álvarez J, Santiuste C, Miguélez MH (2019) Experimental and numerical analysis of the influence of drill point angle when drilling biocomposites. Compos Struct 209:700–709. https://doi.org/10.1016/j.compstruct.2018.11.018

Abilash N, Sivapragash M (2016) Optimizing the delamination failure in bamboo fiber reinforced polyester composite. J King Saud Univ - Eng Sci 28:92–102. https://doi.org/10.1016/j.jksues.2013.09.004

Athijayamani A, Thiruchitrambalam M, Natarajan U, Pazhanivel B (2010) Influence of alkali-treated fibers on the mechanical properties and machinability of roselle and sisal fiber hybrid polyester composite. Polym Compos 31:723–731. https://doi.org/10.1002/pc.20853

Manickam R, Gopinath A (2017) Measurement and analysis of thrust force in drilling sisal-glass fiber reinforced polymer composites. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/197/1/012056

Belaadi A, Laouici H, Bourchak M (2020) Mechanical and drilling performance of short jute fibre-reinforced polymer biocomposites: statistical approach. Int J Adv Manuf Technol 106:1–18. https://doi.org/10.1007/s00170-019-04761-4

Belaadi A, Boumaaza M, Amroune S, Bourchak M (2020) Mechanical characterization and optimization of delamination factor in drilling bidirectional jute fibre-reinforced polymer biocomposites. Int J Adv Manuf Technol 111:2073–2094. https://doi.org/10.1007/s00170-020-06217-6

Tabet Z, Belaadi A, Boumaaza M, Bourchak M (2021) Drilling of a bidirectional jute fibre and cork-reinforced polymer biosandwich structure: ANN and RSM approaches for modelling and optimization. Int J Adv Manuf Technol 117:3819–3839. https://doi.org/10.21203/rs.3.rs-503708/v1

Adda B, Belaadi A, Boumaaza M, Bourchak M (2021) Experimental investigation and optimization of delamination factors in the drilling of jute fiber–reinforced polymer biocomposites with multiple estimators. Int J Adv Manuf Technol 116:2885–2907. https://doi.org/10.1007/s00170-021-07628-9

Lekrine A, Belaadi A, Makhlouf A, Amroune S, Bourchak M, Satha H, Jawaid M (2022) Structural, thermal, mechanical and physical properties of Washingtonia filifera Fibres Reinforced Thermoplastic Biocomposites. Mater Today Commun 103574. https://doi.org/10.1016/j.mtcomm.2022.103574

Boumaaza M, Belaadi A, Bourchak M (2021) The effect of alkaline treatment on mechanical performance of natural fibers-reinforced plaster: part II. Optimization comparison between ANN and RSM statistics. J Nat Fibers 1–16. https://doi.org/10.1080/15440478.2021.1964129

Boumaaza M, Belaadi A, Bourchak M (2021) The effect of alkaline treatment on mechanical performance of natural fibers-reinforced plaster: optimization using RSM. J Nat Fibers 18:2220–2240. https://doi.org/10.1080/15440478.2020.1724236

Boumaaza M, Belaadi A, Bourchak M, Jawaid M, Satha H (2022) Comparative study of flexural properties prediction of Washingtonia filifera rachis biochar bio-mortar by ANN and RSM models. Construct Build Mater 318:125985. https://doi.org/10.1016/j.conbuildmat.2021.125985

Kharwar PK, Verma RK, Singh A (2020) Neural network modeling and combined compromise solution (CoCoSo) method for optimization of drilling performances in polymer nanocomposites. J Thermoplast Compos Mater 0:0892705720939165. https://doi.org/10.1177/0892705720939165

Funding

The authors received financial support from DGRSDT (la Direction Générale de la Recherche Scientifique et du Développement Technologique, Algérie) for their support in this work. Authors Ahmed Belaadi and Messaouda Boumaaza are funded by research project number A11N01UN210120210001 from January 1, 2021.

Author information

Authors and Affiliations

Contributions

Ahmed Belaadi: conceptualization, investigation, methodology, supervision, writing – review and editing. Messaouda Boumaaza: conceptualization, investigation, writing – review and editing. Hassan Alshahrani: investigation, writing – review and editing. Mostefa Bourchak: investigation, writing – review and editing. Mohammad Jawaid: investigation, writing – review and editing.

Corresponding author

Ethics declarations

Ethics approval

The work contains no libelous or unlawful statements, does not infringe on the rights of others, or contains material or instructions that might cause harm or injury.

Consent to participate

The authors consent to participate.

Consent for publication

The authors consent to publish.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Belaadi, A., Boumaaza, M., Alshahrani, H. et al. Drilling performance prediction of HDPE/Washingtonia fiber biocomposite using RSM, ANN, and GA optimization. Int J Adv Manuf Technol 123, 1543–1564 (2022). https://doi.org/10.1007/s00170-022-10248-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10248-6