Abstract

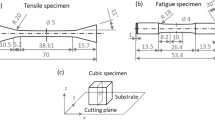

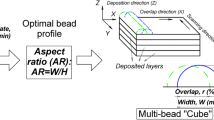

Laser powder bed fusion is widely used for tooling applications, such as mould insert: conformal cooling channels are designed to decrease cycling time and homogenize the cooling rate. The Achilles’ heel of additive manufacturing mould is the cooling channels close to the surface which generate high stress concentration and are not machined; as a result, they create weaknesses in the part and are likely to reduce the lifespan of the mould. It is necessary to study the impact of such channels on properties (fatigue, residual stresses, microstructure) and determine optimized laser strategies to reduce porosity that may occur near a contour. Residual stresses were first estimated above an internal channel after different heat treatments, and fatigue specimens were printed with a 3-mm diameter channel on an EOS M270 printer using different strategies such as several contours with a concentric offset. The impact of these strategies on fatigue properties was analysed through microstructural observations. Here, it was found that a double contour with an offset improved the fatigue life of the part by more than 10 times compared to the standard single contour strategy.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

Code availability

N/A; no codes have been written for this study.

References

Kang J, Shangguan H, Deng C, Hu Y, Yi J, Wang X, Huang T (2018) Additive manufacturing-driven mold design for castings. Addit Manuf 22:472–478

Kuo CC, Jiang ZF, Lee JH (2019) Effects of cooling time of molded parts on rapid injection molds with different layouts and surface roughness of conformal cooling channels. Int J Adv Manuf Technol 103(5):2169–2182

Kuo CC, Jiang ZF, Yang MX, You BJ, Zhong WC (2021) Effects of cooling channel layout on the cooling performance of rapid injection mold. Int J Adv Manuf Technol 114(9):2697–2710

Shakerin S, Hadadzadeh A, Amirkhiz BS, Shamsdini S, Li J, Mohammadi M (2019) Additive manufacturing of maraging steel-H13 bimetals using laser powder bed fusion technique. Addit Manuf 29:100797

Torres-Alba A, Mercado-Colmenero JM, Caballero-Garcia JDD, Martin-Doñate C (2021) A hybrid cooling model based on the use of newly designed fluted conformal cooling channels and fastcool inserts for green molds. Polymers 13(18):3115

Torres-Alba A, Mercado-Colmenero JM, Caballero-Garcia JDD, Martin-Doñate C (2021) Application of new triple hook-shaped conformal cooling channels for cores and sliders in injection molding to reduce residual stress and warping in complex plastic optical parts. Polymers 13(17):2944

Godec D, Šercer M, Rujnić‐Sokele M (2008) Influence of hybrid mould on moulded parts properties. Rapid Prototyp J

Turk C, Zunko H, Aumayr C et al (2019) Advances in maraging steels for additive manufacturing. Berg Huettenmaenn Monatsh 164:112–116

Dehgahi S, Sanjari M, Ghoncheh MH, Amirkhiz BS, Mohammadi M (2021) Concurrent improvement of strength and ductility in heat-treated C300 maraging steels produced by laser powder bed fusion technique. Addit Manuf 39:101847

Chadha K, Tian Y, Bocher P, Spray JG, Aranas C (2020) Microstructure evolution, mechanical properties and deformation behavior of an additively manufactured maraging steel. Materials 13(10):2380

Hanzl P, Zetek M, Bakša T, Kroupa T (2015) The influence of processing parameters on the mechanical properties of SLM parts. Procedia Eng 100(1):1405–1413

Saby Q, Buffiére JY, Maire E, Joffre T, Bajolet J, Garabédian S, Boulnat X (2021) Laser Powder Bed Fusion printability of cobalt-free steel powders for manufacturing injection molds. Addit Manuf 102031

Salandre M, Garabedian S, Gaillard G, Williamson T, Joffre T (2021) Development of a new tooling steel (L40) for laser powder bed fusion: influence of particles size distribution and powder atomization on mechanical performances. Adv Eng Mater

Nath SD, Irrinki H, Gupta G, Kearns M, Gulsoy O, Atre S (2019) Microstructure-property relationships of 420 stainless steel fabricated by laser-powder bed fusion. Powder Technol 343:738–746

Aleksandr K, Ferdinando S, Joel R, Joel C, Jordan M, Thomas J (2021) Effect of direct energy deposition parameters on morphology, residual stresses, density, and microstructure of 1.2709 maraging steel. Int J Adv Manuf Technol 117(3):1287–1301

Ramiro P, Ortiz M, Alberdi A, Lamikiz A (2020) Geometrical model and strategy in single and multilayer structures deposited by powder-fed Directed Energy Deposition. Procedia CIRP 94:352–356

Félix-Martínez C, Ibarra-Medina J, Fernández-Benavides DA, Cáceres-Díaz LA, Alvarado-Orozco JM (2021) Effect of the parametric optimization and heat-treatment on the 18Ni-300 maraging steel microstructural properties manufactured by directed energy deposition. Int J Adv Manuf Technol 115(11):3999–4020

Garabedian S, Joffre T (2021) Fabrication additive Optimisation par refroidissement conforme des moules d'injection, Editions T.I., bm7945

Han S, Salvatore F, Rech J, Bajolet J (2020) Abrasive flow machining (AFM) finishing of conformal cooling channels created by selective laser melting (SLM). Precis Eng 64:20–33

Zhang M, Sun CN, Zhang X, Goh PC, Wei J, Hardacre D, Li H (2017) Fatigue and fracture behaviour of laser powder bed fusion stainless steel 316L: Influence of processing parameters. Mater Sci Eng A 703:251–261

Cabanettes F, Joubert A, Chardon G, Dumas V, Rech J, Grosjean C, Dimkovski Z (2018) Topography of as built surfaces generated in metal additive manufacturing: a multi scale analysis from form to roughness. Precis Eng 52:249–265

Afkhami S, Piili H, Salminen A, Björk T (2019) Effective parameters on the fatigue life of metals processed by powder bed fusion technique: a short review. Procedia Manuf 36:3–10

Afkhami S, Dabiri M, Piili H, Björk T (2021) Effects of manufacturing parameters and mechanical post-processing on stainless steel 316L processed by laser powder bed fusion. Mater Sci Eng A 802:140660

Esmaeilizadeh R, Keshavarzkermani A, Ali U, Behravesh B, Bonakdar A, Jahed H, Toyserkani E (2021) On the effect of laser powder-bed fusion process parameters on quasi-static and fatigue behaviour of Hastelloy X: a microstructure/defect interaction study. Addit Manuf 38:101805

Khan HM, Karabulut Y, Kitay O, Kaynak Y, Jawahir IS (2020) Influence of the post-processing operations on surface integrity of metal components produced by laser powder bed fusion additive manufacturing: a review. Mach Sci Technol 25(1):118–176

ISO 1099 (2017) - Metallic materials — fatigue testing — axial force-controlled method

Bonnet P, Hermite X, Huther I, Lefebvre F (2021) Guide for selecting a fatigue testing method and the associated statistical analysis, Cetim Edition. ISBN 978–2–36894–105–8

EOS acier maraging MS1 M270 (2007) https://www.afu-mp.com/. https://www.afu-mp.com/wpcontent/uploads/2015/01/EOS_acier_maraging_ms1_fr.pdf

de Oliveira AR, de Oliveira VF, Teixeira JC, Del Conte EG (2021) Investigation of the build orientation effect on magnetic properties and Barkhausen Noise of additively manufactured maraging steel 300. Additive Manuf. https://doi.org/10.1016/j.addma.2020.101827

Bonnet P, Hermite X, Huther I, Lefebvre F (2016) Guide pour le choix d’une méthode d’essais de fatigue et de l’analyse statistique associée, Collection fatigue

Venkatanarayana G, Arumugham S, Lakshmanan TS, Prasad Rao P (1996) Effect of temperature and strain rate on tensile behaviour of M250 maraging steel. Mater Sci Technol 12(7):607–609

Funding

The research was supported internally by IPC and the CETIM: the authors did not receive any external funding.

Author information

Authors and Affiliations

Contributions

All the authors have contributed to the design of the study and to the writing process of this manuscript.

Corresponding author

Ethics declarations

Ethics approval

N/A; the experiments did not involve any human participants.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Grosjean, C., Borneat, JC., Hauteville, R. et al. Effects of channel contour laser strategies on fatigue properties and residual stresses of laser powder bed printed maraging steel. Int J Adv Manuf Technol 123, 3109–3120 (2022). https://doi.org/10.1007/s00170-022-10246-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10246-8