Abstract

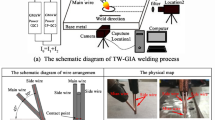

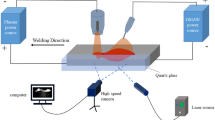

Triple-wire gas indirect arc welding (TW-GIA) is a new high-efficiency technology with low heat input and high deposition rate. However, the research on the arc conductive channel and energy transfer characteristics of TW-GIA is not deep enough, which makes it impossible to accurately adjust the heat transfer and restricts the further application of this technology. In this paper, the spectrometer was used to collect arc spectral information, the Boltzmann diagram method was adopted to estimate electron temperature and electron density, and physical models were constructed to discuss the heat transfer mechanism. The results show that the conductive channel of TW-GIA is established between the main wire and the side wires. Due to the coupled magnetic field generated by the two current branches, the Lorentz force on the TW-GIA arc plasma is directed towards the extension of the main wire, resulting in the arc to be compressed in the X-axis and elongated in the Z-axis as the welding current increases. The electron temperature gradient an “inverted cone” characteristic, which can be divided into high-temperature area (HTA), low-temperature area (LTA), and peripheral area (PA). The ranges of HTA and LTA both expand with the increase of welding current, and the size ratio of HTA to LTA is gradually increased. Due to the reduction of electron density and contact area, the heat-affected zone width with three areas is smaller than that of GMAW, and the average temperature around the weld is reduced by 24.3%, 31.8%, and 45.9%, respectively, when adopting HTA, LTA, and PA.

Similar content being viewed by others

Data availability

All the data have been presented in the manuscript.

References

Gao Y, Zhang Y, Li J, Liu K, Xu Y, Zhou JP (2021) Research on the performance of laser-MIG arc tandem welding of CP-Ti/304 stainless steel bimetallic sheets. Mater Lett 305(15):130805. https://doi.org/10.1016/j.matlet.2021.130805

Kim JY, Van D, Lee J, Yim J, Lee SH (2021) The effect of a hot-wire in the tandem GMAW process ascertained by developing a multiphysics simulation model. J Mech Sci Technol 35(1):267–273. https://doi.org/10.1007/s12206-020-1226-9

Lahnsteiner R (1992) TIME process - an innovative MAG welding process. Weld Rev Int 11(1):17–20

Zhang Y (2007) Metal transfer in double-electrode gas metal arc welding. J Manuf Sci Eng 129(6):991–999. https://doi.org/10.1115/1.2769729

Purwaningrum Y, Kusriyanto M, Kurniawan R, Rizky O (2018) Effect of DE-GMAW (Double electrode gas metal arc welding)’s resistance on mechanical and physical properties of aluminium alloy weld. Key Eng Mater 789:64–68. https://doi.org/10.4028/www.scientific.net/KEM.789.64

Wu DT, Zou Y, Zhao GL, Shi C (2020) Wear-resistant surfacing layer preparated by high efficiency twin-wire indirect arc welding. Mater Sci Forum 985:229–239. https://doi.org/10.4028/www.scientific.net/MSF.985.229

An Q, Wen Y, Matsuda K, Xu J, Zou Y (2021) Corrosion resistance and high temperature wear behavior of carbide-enhanced austenite-based surfacing layer prepared by twin-wire indirect arc welding. Mater Res Express 8(1):016529. https://doi.org/10.1088/2053-1591/abda65

Wu DT, Hu C, Zhao W, Zhang YG, Zou Y (2019) Influence of external magnetic field on twin-wire indirect arc surfacing stainless steel layer. Vacuum 169:1–7. https://doi.org/10.1016/j.vacuum.2019.108958

Fang DS, Song G, Liu LM (2016) A novel method of triple-wire gas indirect arc welding. Mater Manuf Process 31(3):352–358. https://doi.org/10.1080/10426914.2015.1058949

Liu LM, Wang ZL, Zhang TY, Ba XL (2022) Analysis of metal transfer and weld forming characteristics in triple-wire gas indirect arc welding. Int J Adv Manuf Tech 120(9–10):6777–6788. https://doi.org/10.1007/s00170-022-09119-x

Liu LM, Yu SB, Song G, Hu CH (2019) Analysis of arc stability and bead forming with high-speed TW-GIA welding. J Manuf Process 46:67–76. https://doi.org/10.1016/j.jmapro.2019.08.023

Zhang Z, Wu DT, Zou Y (2018) Effect of bypass coupling on droplet transfer in twin-wire indirect arc welding. J Mater Process Tech 262:123–130. https://doi.org/10.1016/j.jmatprotec.2018.06.032

Miao Y, Xu X, Wu B, Li X, Han D (2014) Effects of bypass current on the stability of weld pool during double sided arc welding. J Mater Process Tech 214(8):1590–1596. https://doi.org/10.1016/j.jmatprotec.2014.02.029

Liu LM, Hu CH, Yu SB, Song G (2019) A triple-wire indirect arc welding method with high melting efficiency of base metal. J Manuf Process 44:252–260. https://doi.org/10.1016/j.jmapro.2019.05.022

Liu LM, Yu SB, Hu CH (2019) Analysis of arc shape and weld forming in triple-wire indirect arc welding. Trans China Weld Inst 40(6):1–6

Wang ZL, Zhang TY, Dong XN, Liu LM (2022) Suppression of humping bead in high-speed triple-wire gas indirect arc welding. Int J Adv Manuf Tech. https://doi.org/10.1007/s00170-022-10031-7

Ogino Y, Hirata Y, Kawata J, Nomura K (2013) Numerical analysis of arc plasma and weld pool formation by a tandem TIG arc. Weld World 57(3):411–423. https://doi.org/10.1007/s40194-013-0040-8

Ding XP, Li H, Wei HL, Liu JQ (2016) Numerical analysis of arc plasma behavior in double-wire GMAW. Vacuum 124:46–54. https://doi.org/10.1016/j.vacuum.2015.11.006

Wu XY, Tian RY, Zhang ZY, Li YA, Cheng J (2020) Study on the arcs interaction in plasma-GMAW hybrid welding. J Phys Conf Ser 1622(1):012030. https://doi.org/10.1088/1742-6596/1622/1/012030

Wang L, Chen J, Jiang CL, Wu CS (2020) Numerical simulations of arc plasma under external magnetic field-assisted gas metal arc welding. Aip Adv 10(6):065030. https://doi.org/10.1063/5.0009935

Shi L, Song YL, Xiao TJ, Ran GW (2012) Physical characteristics of welding arc ignition process. Chin J Mech Eng 25(4):786–791. https://doi.org/10.3901/CJME.2012.04.786

Xiao X, Hua XM, Li F, Wu YX (2014) A modified Fowler-Milne method for monochromatic image analysis in multi-element arc plasma welding. J Mater Process Tech 14:1–28. https://doi.org/10.1016/j.jmatprotec.2014.05.026

Xiao X, Hua X, Wu Y (2015) Comparison of temperature and composition measurement by spectroscopic methods for argon–helium arc plasma. Opt Laser Technol 66:138–145. https://doi.org/10.1016/j.optlastec.2014.08.017

Zhu YL, Xu XK, Liu RT, Liu LM (2021) Magnetic-enhanced common conductive channel characteristics of two-electrode TIG. Int J Adv Manuf Tech 116:3217–3229. https://doi.org/10.1007/s00170-021-07674-3

Valensi F, Pellerin S, Boutaghane A, Dzierzega K, Pellerin N, Briand F (2011) LTE experimental validation in a gas metal arc welding plasma column. Contrib Plasm Phsys 51(3):293–296. https://doi.org/10.1002/ctpp.201000061

Sabbaghzadeh J, Dadras S, Torkamany M (2007) Comparison of pulsed Nd: YAG laser welding qualitative features with plasma plume thermal characteristics. J Phys D Appl Phys 40(4):1047–1051. https://doi.org/10.1088/0022-3727/40/4/019

National Institute of Standards and Technology (2022) https://www.nist.gov/pml/atomic-spectra-database

Liu LM, Chen MH (2011) Interactions between laser and arc plasma during laser–arc hybrid welding of magnesium alloy. Opt Laser Eng 49(9–10):1224–1231. https://doi.org/10.1016/j.optlaseng.2011.04.012

Goldak J, Chakravarti A, Bibby M (1984) A new finite element model for welding heat sources. Metall Trans B 15(2):299–305. https://doi.org/10.1007/BF02667333

Xu JL, Jing SX (1981) plasma physics. Atomic energy press, Beijing in Chinese

Funding

This work was supported by the National Natural Science Foundation of China (No. 52175290).

Author information

Authors and Affiliations

Contributions

Liming Liu: conceptualization, funding acquisition. Zeli Wang: operational experiments, methodology, writing-original draft, formal analysis. Xinze Lv: assist experiment, validation. Runtao Liu: language translation. Tianyi Zhang: data calculation.

Corresponding author

Ethics declarations

Ethical approval

The paper follows the guidelines of the Committee on Publication Ethics (COPE).

Consent to participate

The authors declare that they all consent to participate this research.

Consent for publication

The authors declare that they all consent to publish the manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, L., Wang, Z., Lv, X. et al. Analysis of conductive channel and heat transfer mechanism of triple-wire gas indirect arc welding. Int J Adv Manuf Technol 123, 1285–1296 (2022). https://doi.org/10.1007/s00170-022-10230-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10230-2