Abstract

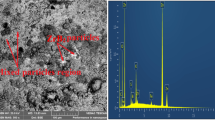

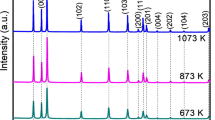

The numerous industrial application of mild steel despite its susceptibility to degradation on exposure to the environment has called for the continuous search for materials that can protect its surface from contaminants which could affect its inherent properties. This paper therefore examined the corrosion-resistance, hardness, and microstructure properties of unripe plantain peel (UPP) nanoparticle-reinforced Zn–ZnO–MgO composite coatings deposited on the surface of mild steel (AISI 1015 Carbon Steel). The corrosion properties of the coated steel samples were investigated using the potentiodynamic polarization technique, utilizing simulated seawater (3.65% NaCl solution) as the test medium. The hardness of the coated steel samples was studied using the Brinell hardness method, while the microstructure properties were investigated using XRD and SEM/EDS. The as-received mild steel sample was observed to exhibit a hardness value and corrosion rate of 136.8 kgf/mm2 and 8.6272 mm/year, respectively, while the Zn–10ZnO–10MgO-coated mild steel sample exhibited a hardness value and corrosion rate of 246.53 and 1.7698 mm/year, respectively. Relative to the other samples, the Zn–10ZnO–10MgO–6UPP-coated mild steel (sample coated with 10 g/L of ZnO, 10 g/L of MgO and 6 g/L of UPP) exhibited a highest hardness value and lowest corrosion rate of 254.77 kgf/mm2 and 0.6645 mm/year, respectively. These corrosion rate and hardness values of the Zn–10ZnO–10MgO–6UPP-coated mild steel sample showed that the unripe plantain peel nanoparticles further enhanced the strengthening and passivating ability of Zn–ZnO–MgO–UPP coating. The SEM micrographs revealed that the Zn–ZnO–MgO–UPP coating possessed a more refined microstructure relative to the Zn–ZnO–MgO coating, signifying the grain refining ability of the unripe plantain peel nanoparticles. The EDS additionally indicated the occurrence of crucial and dispersion strengthening elements in the coatings. The XRD profile of the coatings exhibited high intensities, which signified that the coatings have high stability and good texture with microstructural and chemical homogeneity.

Similar content being viewed by others

Data availability

The authors declare that the data and list of materials used for this research are included in the manuscript.

Code availability

NOVA 2.1.2 software was used for the corrosion analysis.

References

Ohaeri E, Eduok U, Szpunar J (2018) Hydrogen related degradation in pipeline steel: a review. Int J Hydrogen Energy 43:14584–14617

Akpan BJ, Akande IG, Fayomi OSI, Oluwasegun KM (2022) Investigation of hardness, microstructure and anti-corrosion properties of Zn-ZnO composite coating doped unripe plantain peel particles. Case Studies in Chemical and Environmental Engineering (CSCEE). https://doi.org/10.1016/j.cscee.2022.100187

Bhandari J, Khan F, Abbassi R, Garaniya V, Ojeda R (2015) Modelling of pitting corrosion in marine and offshore steel structures–a technical review. J Loss Prev Process Ind 37:39–62

Murmu M, Saha SK, Murmu NC, Banerjee P (2019) Amine cured double Schiff base epoxy as efficient anticorrosive coating materials for protection of mild steel in 3.5% NaCl medium. J Mole Liq 278:521–535

Shivakumar M, Dharmaprakash MS, Manjappa S, Nagashree KL (2017) Corrosion inhibition performance of lignin extracted from black liquor on mild steel in 0.5 M H2SO4 acidic media.Portugaliae Electrochimica Acta 35:351–359

Rahman Rashid RA, Javed MA, Barr C, Palanisamy S, Matthews N, Dargusch MS (2021) Effect of in situ tempering on the mechanical, microstructural and corrosion properties of 316L stainless steel laser-cladded coating on mild steel. Int J Adv Manuf Technol 117:2949–2958

Fayomi OSI, Akande IG, Ighravwe DE, Aikhuele DO (2021) Inhibitive characteristics of cefalexin drug addition on corrosion evolution of mild steel in chloride medium. Key Eng Mater 886:119–125

Wu W, Wang Q, Yang L, Liu Z, Li X, Li Y (2020) Corrosion and SCC initiation behavior of low-alloy high-strength steels microalloyed with Nb and Sb in a simulated polluted marine atmosphere. J Market Res 9:12976–12995

Wang R, Shenoi RA, Sobey A (2018) Ultimate strength assessment of plated steel structures with random pitting corrosion damage. J Constr Steel Res 143:331–342

Olugbade TO (2021) Electrochemical characterization of the corrosion of mild steel in saline following mechanical deformation. Anal Lett 54:1055–1067

Fayomi OSI, Akande IG, Ofo C (2021) Investigation of corrosion resistance and microstructural performance of Zn-MgO-WB composite coating on mild steel. Key Eng Mater 886:159–167

Kurth JC, Krauss PD, Foster SW (2019) Corrosion management of maritime infrastructure.transportation Res Rec 2673:2–14

Arul A, Sivagnanam S, Dey A, Mukherjee O, Ghosh S, Das P (2020) The design and development of short peptide-based novel smart materials to prevent fouling by the formation of non-toxic and biocompatible coatings. RSC Adv 10:13420–13429

Tombaugh RS, Harpel R (2020) Premature failure of an intumescent coating: truth and consequences. J Prot Coat Linings 37:8–13

Fusco MA, Oldham CJ, Parsons GN (2019) Investigation of the corrosion behavior of atomic layer deposited Al2O3/TiO2 nanolaminate thin films on copper in 0.1 M NaCl. Materials 12:672

Alizadeh M, Safaei H (2018) Characterization of Ni-Cu matrix, Al2O3 reinforced nano-composite coatings prepared by electrodeposition. Appl Surf Sci 456:195–203

Shourgeshty M, Aliofkhazraei M, Karimzadeh A (2019) Study on functionally graded Zn–Ni–Al2O3 coatings fabricated by pulse-electrodeposition. Surf Eng 35:167–176

Fayomi OSI, Oluwadare GA, Fakehinde OB, Akande IG, Nwachia W, Oziegbe U, Russell AJ (2019) Evolution of physical and mechanical characteristics of deposited composite coatings on A356 mild steel. Int J Adv Manuf Technol 103:2621–2625

Manivannan R, Victoria SN (2018) Preparation of chalcogenide thin films using electrodeposition method for solar cell applications–a review. Sol Energy 173:1144–1157

Lelevic A, Walsh FC (2019) Electrodeposition of NiP alloy coatings: a review. Surf Coat Technol 369:198–220

Das S, Banthia S, Patra A, Sengupta S, Singh SB (2018) Novel bilayer ZnNi/NiCoSiC nanocomposite coating with exceptional corrosion and wear properties by pulse electrodeposition. J Alloy Compd 738:394–404

Torkamani AD, Velashjerdi M, Abbas A, Bolourchi M, Maji P (2021) Electrodeposition of Nickel matrix composite coatings via various Boride particles: a review. J Compos Compd 3:106–113

Morcillo M, Díaz I, Cano H, Chico B, De La Fuente D (2019) Atmospheric corrosion of weathering steels. Overview for engineers. Part II: testing, inspection, maintenance. Constr Build Mater 222:750–765

Jassim RA, Sando MS, Farhan AM (2022) Protection of galvanized steel from corrosion in salt media using sulfur nanoparticles. Baghdad Sci J 19:347–354

Ridosic M, García-Lecina E, Salicio-Paz A, Bajat J (2020) The advantage of ultrasound during electrodeposition on morphology and corrosion stability of Zn-Co alloy coatings. Transactions of the IMF 98:114–120

LeBozec N, Thierry D, Persson D, Riener CK, Luckeneder G (2019) Influence of microstructure of zinc-aluminium-magnesium alloy coated steel on the corrosion behavior in outdoor marine atmosphere. Surf Coat Technol 374:897–909

Fayomi OSI, Joseph OO, Akande IG, Ohiri CK, Enechi KO, Udoye NE (2019) Effect of CCBP doping on the multifunctional Al-0.5 Mg-15CCBP superalloy using liquid metallurgy process for advanced application. J Alloys Compd 783:246–255

Adetayo OA, Jubril O (2019) Effect of ripe and unripe plantain peel ash on concrete workability and compressive strength. FUOYE J Eng Technol 4:145–148

Fayomi OSI, Akande IG, Popoola API, Popoola SI, Daramola D (2019) Structural characterization and corrosion properties of electroless processed Ni-P-MnO2 composite coatings on SAE 1015 steel for advanced applications. J Sci Adv Mater Dev 4:285–289

Li SF, Geng K, Misra RDK, Cui JY, Ye D, Liu Y, Yang YF (2020) Commercial scale uniform powder coating for metal additive manufacturing. JOM 72:4639–4647

Tishkevich DI, Grabchikov SS, Tsybulskaya LS, Shendyukov VS, Perevoznikov SS, Trukhanov SV, Vinnik DA (2018) Electrochemical deposition regimes and critical influence of organic additives on the structure of Bi films. J Alloys Compd 735:1943–1948.

He L, Chen L, Xu Y (2017) Interfacial structure, mechanical properties and thermal stability of CrAlSiN/CrAlN multilayer coatings. Mater Charact 125:1–6

Tristijanto H, Ilman MN, Iswanto PT (2020) Corrosion inhibition of welded of X–52 steel pipelines by sodium molybdate in 3.5% NaCl solution. Egypt J Pet 29:155–162

Akande IG, Oluwole OO, Fayomi OSI (2019) Optimizing the defensive characteristics of mild steel via the electrodeposition of Zn-Si3N4 reinforcing particles. Defence Technol 15:526–532

Deyab MA (2016) Electrochemical investigations on pitting corrosion inhibition of mild steel by provitamin B5 in circulating cooling water. Electrochim Acta 202:262–268

Saadawy M (2016) Effect of inorganic anions on the pitting behaviour of austenitic stainless steel 304 in H2SO4 solution containing chloride ion. Int J Electrochem Sci 11:2345–2359

Golabadi M, Aliofkhazraei M, Toorani M (2021) Corrosion behavior of zirconium-pretreated/epoxy-coated mild steel: new approach for determination of cathodic disbondment resistance by electrochemical impedance spectroscopy. J Alloy Compd 873:1–19

Fayomi OSI, Akande IG, Popoola API (2018) Corrosion protection effect of chitosan on the performance characteristics of A6063 alloy. J Bio-and Tribo-Corros 4:1–6

Yule LC, Shkirskiy V, Aarons J, West G, Bentley CL, Shollock BA, Unwin PR (2019) Nanoscale active sites for the hydrogen evolution reaction on low carbon steel. J Phys Chem C 123:24146–24155

Xie Y, Meng X, Mao D, Qin Z, Wan L, Huang Y (2021) Homogeneously dispersed graphene nanoplatelets as long-term corrosion inhibitors for aluminum matrix composites. ACS Appl Mater Interfaces 13:32161–32174

Akande IG, Oluwole OO, Fayomi OSI (2022) Production of lightweight Zn–ZrB2 nanocomposite coatings for mechanical, microstructure and corrosion-resistance improvement of carbon steel in acidic medium. Ceram Int 48:22155–22163

Dehgahi S, Amini R, Alizadeh M (2017) Microstructure and corrosion resistance of Ni-Al2O3-SiC nanocomposite coatings produced by electrodeposition technique. J Alloy Compd 692:622–628

Jin Y, Chen Z, Yang W, Yin X, Chen Y, Liu Y (2020) Electrosynthesis of molybdate-doped P (ANI-co-PY) copolymer coating in ionic liquid for corrosion protection of 304 stainless steel. J Taiwan Inst Chem Eng 117:171–181

Wan Q, Ding H, Yousaf MI, Chen YM, Liu HD, Hu L, Yang B (2016) Corrosion behaviors of TiN and Ti-Si-N (with 2.9 at.% and 5.0 at.% Si) coatings by electrochemical impedance spectroscopy. Thin Solid Films 616:601–607

Huang H, Liu H, Wang C, Sun J, Bai J, Xue F, Ma A (2019) Potential of multi-pass ECAP on improving the mechanical properties of a high-calcium-content Mg-Al-Ca-Mn alloy. J Magnes Alloy 7:617–627

Rasooli A, Safavi MS, Hokmabad MK (2018) Cr2O3 nanoparticles: A promising candidate to improve the mechanical properties and corrosion resistance of Ni-Co alloy coatings. Ceram Int 44:6466–6473

Yang L, Yang X, Zhang T, Sun R (2021) Optimization of microstructure and properties of composite coatings by laser cladding on titanium alloy. Ceram Int 47:2230–2243

Alipour K, Nasirpouri F (2019) Effect of morphology and surface modification of silica nanoparticles on the electrodeposition and corrosion behavior of zinc-based nanocomposite coatings. J Electrochem Soc 166:D1–D9

Wang C, Farhat Z, Jarjoura G, Hassan MK, Abdullah AM (2018) Indentation and bending behavior of electroless Ni-P-Ti composite coatings on pipeline steel. Surf Coat Technol 334:243–252

Zhao Z, Liu F, Cao L, Du Y, Li B, Li J, Xu Y (2021) Investigation of indentation response, scratch resistance, and wear behavior of tungsten carbide coatings fabricated by two-step interstitial carburization on tungsten. Ceram Int 47:30636–30647

Abedi M, Abdollah-Zadeh A, Vicenzo A, Bestetti M, Movassagh-Alanagh F, Damerchi E (2019) A comparative study of the mechanical and tribological properties of PECVD single layer and compositionally graded TiSiCN coatings. Ceram Int 45:21200–21207

Li Z, Farhat Z (2020) Hertzian indentation behavior of electroless Ni-P-Ti composite coatings. Metall and Mater Trans A 51:3674–3691

Funding

This research was funded by the authors in collaboration with Surface Engineering Research Centre, Ota, Ogun state, Nigeria.

Author information

Authors and Affiliations

Contributions

Itopa Godwin Akande: co-supervision of the research, support in the material selection and corrosion analysis, writing the manuscript, reviewing and editing the manuscript, and revised the manuscript. Ojo Sunday Isaac Fayomi: putting forward the concept of the research methodology, and supervision of the research and reviewing of the manuscript. Bassey Jonah Akpan: research analysis, design of experiment, characterization of samples, and writing the manuscript.

Corresponding author

Ethics declarations

Ethics approval

The authors confirm that they have abided to the publication ethics and state that this work is original and has not been used for publication anywhere before.

Consent to participate

The authors are willing to participate in journal promotions and updates.

Consent for publication

The authors give consent to the journal regarding the publication of this work.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Akande, I.G., Fayomi, O.S.I. & Akpan, B.J. Development of UPP nanoparticles reinforced Zn–ZnO–MgO composite coating for corrosion-resistance, hardness, and microstructure property enhancement of AISI 1015 carbon steel for automotive and marine applications. Int J Adv Manuf Technol 123, 999–1008 (2022). https://doi.org/10.1007/s00170-022-10222-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10222-2