Abstract

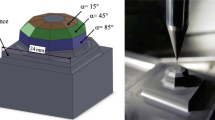

The micro-milling process is one of the most suitable methods for the accurate machining of devices in the micro-domain and is implemented for a wide range of materials. Fine-grained graphite is extensively used as electrode material for micro-electrical discharge machining because of its excellent thermal, chemical, and electrical properties. Dimensional accuracy and form accuracy are among main goals in the micro-milling process of the 3D micro-form electrodes. Among the numerous factors that affect the quality of the machined micro-components, tool deflection is the most significant. This paper investigates the influence of fine-grained graphite type, depth of cut, tool wear, cutting edge radius size, workpiece inclination angle, and machining strategy as control factors on tool deflection. The experimental results presented in this paper provide important insight into tool deflection issues for improving machining accuracy in micro-milling process of graphite electrodes with complex 3D geometry and high aspect ratio.

Similar content being viewed by others

Data Availability

Not applicable.

Code availability

Not applicable.

References

Huo D, Cheng K (2013) Overview of micro cutting. In: Cheng K, Huo D (eds) Micro-cutting: fundamentals and applications. John Wiley & Sons, Chichester, pp 1–17

O’Toole L, Kang CW, Fang FZ (2021) Precision micro-milling process: state of the art. Adv Manuf 9:173–205. https://doi.org/10.1007/s40436-020-00323-0

Câmara MA, Rubio JCC, Abrão AM, Davim JP (2012) State of the art on micromilling of materials, a review. J Mater Sci Technol 28:673–685. https://doi.org/10.1016/S1005-0302(12)60115-7

Serje D, Pacheco J, Diez E (2020) Micromilling research: current trends and future prospects. Int J Adv Manuf Technol 111:1889–1916. https://doi.org/10.1007/s00170-020-06205-w

Balázs BZ, Geier N, Takács M, Davim JP (2021) A review on micro-milling: recent advances and future trends. Int J Adv Manuf Technol 112:655–684. https://doi.org/10.1007/s00170-020-06445-w

Uriarte L, Eguía J, Egaña F (2009) Micro-milling machines. In: Lamikiz A (ed) López de Lacalle LN. Machine tools for high performance machining. Springer, London, pp 369–397

Uriarte L, Herrero A, Zatarain M, Santiso G, Lopéz de Lacalle LN, Lamikiz A, Albizuri J (2007) Error budget and stiffness chain assessment in a micro-milling machine equipped with tools less than 0.3 mm in diameter. Precis Eng 31:1–12. https://doi.org/10.1016/j.precisioneng.2005.11.010

Wu T, Cheng K, Rakowski R (2012) Investigation on tooling geometrical effects of micro tools and the associated micro milling performance. Proc Inst Mech Eng B: J Eng Manuf 226:1442–1453. https://doi.org/10.1177/0954405412449229

Oliaei SNB, Karpat Y (2016) Influence of tool wear on machining forces and tool deflections during micro milling. Int J Adv Manuf Technol 84:1963–1980. https://doi.org/10.1007/s00170-015-7744-4

Mamedov A, Layegh EK, Lazoglu I (2015) Instantaneous tool deflection model for micro milling. Int J Adv Manuf Technol 79:769–777. https://doi.org/10.1007/s00170-015-6877-9

Huo D, Chen W, Teng X, Lin C, Yang K (2017) Modeling the influence of tool deflection on cutting force and surface generation in micro-milling. Micromachines 8:188. https://doi.org/10.3390/mi8060188

Moges TM, Desai KA, Rao PVM (2018) Modeling of cutting force, tool deflection, and surface error in micro-milling operation. Int J Adv Manuf Technol 98:2865–2881. https://doi.org/10.1007/s00170-018-2415-x

Yuan M, Wang X, Jiao L, Yi J, Liu S (2017) Prediction of dimension error based on the deflection of cutting tool in micro ball-end milling. Int J Adv Manuf Technol 93:825–837. https://doi.org/10.1007/s00170-017-0474-z

Zhang X, Yu T, Wang W (2018) Prediction of cutting forces and instantaneous tool deflection in micro end milling by considering tool run-out. Int J Mech Sci 136:124–133. https://doi.org/10.1016/j.ijmecsci.2017.12.019

Rodríguez P, Labarga JE (2015) Tool deflection model for micromilling processes. Int J Adv Manuf Technol 76:199–207. https://doi.org/10.1007/s00170-014-5890-8

Dow TA, Miller EL, Garrard K (2004) Tool force and deflection compensation for small milling tools. Precis Eng 28:31–45. https://doi.org/10.1016/S0141-6359(03)00072-2

Biermann D, Kahnis P (2010) Analysis and simulation of size effects in micromilling. Prod Eng 4:25–34. https://doi.org/10.1007/s11740-009-0201-1

Heo S, Lee M, Kim SH, Lee W, Min B-K (2015) Compensation of tool deflection in micromilling using workpiece holder control device. Int J Precis Eng Manuf 16:1205–1208. https://doi.org/10.1007/s12541-015-0155-5

Uriarte L, Azcarate S, Herrero A, Lopez de Lacalle LN, Lamikiz A (2008) Mechanistic modelling of the micro end milling operation. Proc Inst Mech Eng B J Eng Manuf 222:23–33. https://doi.org/10.1243/09544054JEM837

Mijušković G, Krajnik P, Kopač J (2015) Analysis of tool deflection in micro milling of graphite electrodes. Int J Adv Manuf Technol 76:209–217. https://doi.org/10.1007/s00170-013-5536-2

Wang CY, Zhou L, Fu H, Hu ZL (2007) High-speed milling of graphite electrode with small diameter endmill. Chin J Mech Eng 20:27–31. https://doi.org/10.3901/CJME.2007.04.027

Zhou L, Wang CY, Qin Z (2009) Tool wear characteristics in high-speed milling of graphite using a coated carbide micro endmill. Proc Inst Mech Eng B J Eng Manuf 223:267–277. https://doi.org/10.1243/09544054JEM1326

Zhou L, Wang CY, Qin Z, Li WH (2004) Wear characteristics of micro-end mill in high speed milling of graphite electrode. Key Eng Mater 259–260:858–863. https://doi.org/10.4028/www.scientific.net/KEM.259-260.858

Huo D, Lin C, Dalgarno K (2014) An experimental investigation on micro machining of fine-grained graphite. Int J Adv Manuf Technol 72:943–953. https://doi.org/10.1007/s00170-014-5730-x

Qiu H, Kubo A (2020) An experimental research on surface roughness of fine-grained graphite machined by micro end mills. J Inst Ind Appl Eng 8:95–103. https://doi.org/10.12792/jiiae.8.95

Mijušković G, Dj C (2021) Investigation, modeling, and optimization of surface roughness in micro-milling of graphite electrodes. Int J Adv Manuf Technol 117:579–590. https://doi.org/10.1007/s00170-021-07762-4

Konig M (1998) Frasbearbeitung von graphitelektroden. Dissertation RWTH Aachen University

López de Lacalle LN, Lamikiz A, Sanchez JA, Salgado MA (2004) Effects of tool deflection in the high-speed milling of inclined surfaces. Int J Adv Manuf Technol 24:621–631. https://doi.org/10.1007/s00170-003-1723-x

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Ethics approval

This paper is our original work and it has not been published elsewhere.

Consent to participate

All authors were fully involved in the study and each of the authors has agreed to participate in this study.

Consent for publication

All authors consent to publish the content in the final manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cica, D., Sredanovic, B. & Mijušković, G. Experimental investigation of tool deflection in micro-milling of fine-grained graphite. Int J Adv Manuf Technol 123, 161–168 (2022). https://doi.org/10.1007/s00170-022-10185-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10185-4