Abstract

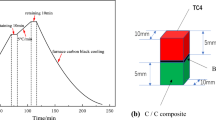

Dissimilar components composed of CFRTP (Carbon Fiber Reinforced Thermoplastic Polymer) and TC4 titanium alloy are increasingly applied in the aerospace field. The scanning mode offers a significant influence on the quality of laser joining joint between CFRTP and TC4 titanium alloy. Therefore, the laser joining between TC4 titanium alloy with surface microgrooves and CFRTP has been implemented under oscillating laser joining mode and linear laser joining mode respectively in the present research. The temperature distribution is qualitatively explored based on the established mathematical model of laser joining between CFRTP and TC4 titanium alloy. The interface morphology and the joining strength of CFRTP/TC4 titanium alloy lap joints under oscillating laser joining and linear laser joining are compared. The results indicate that the simulated temperature distribution shows good agreement with the experimental results. Compared with linear laser joining, the oscillating laser joining weakens the heat concentration and creates a heating zone with larger area and more uniform temperature distribution. The interface morphology of laser joining CFRTP/TC4 titanium alloy joints obtained by oscillating laser joining presents better resin filling and fewer bubble defects due to the temperature variation of the form of unequal amplitude oscillations, with the resin filling ratio of 92.20% and the porosity of 3.78%. In contrast, the linear laser scanning mode with a large number of large-sized bubbles in the filling resin and small-sized fusion gaps distributed at the interface holds a resin filling rate of 60.11% and a porosity of 32.89%. By adopting the joining method with oscillating laser scanning mode, higher quality joints can be obtained with the joining strength of 24.48 MPa.

Similar content being viewed by others

Data availability

Data and materials are available.

Code availability

Not applicable.

References

Konchakova N, Balle F, Barth FJ, Mueller R, Eifler D, Steinmann P (2010) Finite element analysis of an inelastic interface in ultrasonic welded metal/fibre-reinforced polymer joints. Comput Mater Sci 50(1):184–190. https://doi.org/10.1016/j.commatsci.2010.07.024

Berger S, Oefele F, Schmidt M (2015) Laser transmission welding of carbon fiber reinforced thermoplastic using filler material—a fundamental study. J Laser Appl 27(S2):S29009. https://doi.org/10.2351/1.4906391

Wang HP, Chen Y, Guo ZY, Guan YC (2019) Porosity elimination in modified direct laser joining of Ti6Al4V and thermoplastics composites. Appl Sci-Basel 9(3):411. https://doi.org/10.3390/app9030411

Arash B, Wang Q, Varadan VK (2014) Mechanical properties of carbon nanotube/polymer composites. Sci Rep 4:6479. https://doi.org/10.1038/srep06479

Liu SY, Zhou J, Li YQ, Zhang XY (2019) Using reaction heat of laser-induced Al-Ti-C interlayer to connect CFRTP/aluminum. Opt Laser Technol 113:365–373. https://doi.org/10.1016/j.optlastec.2018.12.044

Li Y, Zhan XH, Gao CY, Wang HE, Yang Y (2019) Comparative study of infrared laser surface treatment and ultraviolet laser surface treatment of CFRP laminates. Int J Adv Manuf Technol 102:4059–4071. https://doi.org/10.1007/s00170-019-03368-z

Jha AK, Singh SK, Kiranmayee MS, Sreekumar K, Sinha PP (2010) Failure analysis of titanium alloy (Ti6Al4V) fastener used in aerospace application. Eng Fail Anal 17(6):1457–1465. https://doi.org/10.1016/j.engfailanal.2010.05.007

Khanna N, Davim JP (2015) Design-of-experiments application in machining titanium alloys for aerospace structural components. Measurement 61:280–290. https://doi.org/10.1016/j.measurement.2014.10.059

Marsh G (2014) Composites and metals—a marriage of convenience? Reinf Plast 58(2):38–42. https://doi.org/10.1016/S0034-3617(14)70108-0

Gao QY, Li Y, Wang HE, Liu WP, Shen HL, Zhan XH (2019) Effect of scanning speed with UV laser cleaning on adhesive bonding tensile properties of CFRP. Appl Compos Mater 26(4):1087–1099. https://doi.org/10.1007/s10443-019-09768-4

Tan XH, Zhang J, Shan JG, Yang SL, Ren JL (2015) Characteristics and formation mechanism of porosities in CFRP during laser joining of CFRP and steel. Compos Pt B-Eng 70:35–43. https://doi.org/10.1016/j.compositesb.2014.10.023

Wang HL, Xiao XC, Xiao GX, Fan HT, Arinez J (2019) Laser joining of carbon-fiber-reinforced polymer and metal with high-strength and corrosion-resistant bonds. Procedia Manufacturing 34:42–48. https://doi.org/10.1016/j.promfg.2019.06.112

Lambiase F, Genna S (2017) Laser-assisted direct joining of AISI304 stainless steel with polycarbonate sheets: thermal analysis, mechanical characterization, and bonds morphology. Opt Laser Technol 88:205–214. https://doi.org/10.1016/j.optlastec.2016.09.028

Lambiase F, Genna S, Kant R (2018) A procedure for calibration and validation of FE modelling of laser-assisted metal to polymer direct joining. Opt Laser Technol 98:363–372. https://doi.org/10.1016/j.optlastec.2017.08.016

Van Der Straeten K, Olowinsky A, Gillner A (2018) Laser-based plastic-metal-joining with self-organizing microstructures considering different load directions. J Laser Appl 30(3):032401. https://doi.org/10.2351/1.5040616

Jiao JK, Xu ZF, Wang Q, Sheng LY, Zhang WW (2018) CFRTP and stainless steel laser joining: thermal defects analysis and joining parameters optimization. Opt Laser Technol 103:170–176. https://doi.org/10.1016/j.optlastec.2018.01.023

Jiao JK, Zou Q, Ye YY, Xu ZF, Sheng LY (2021) Carbon fiber reinforced thermoplastic composites and TC4 alloy laser assisted joining with the metal surface laser plastic-covered method. Compos Pt B-Eng 213:108738. https://doi.org/10.1016/j.compositesb.2021.108738

Tao W, Su X, Chen YB, Tian Z (2019) Joint formation and fracture characteristics of laser welded CFRP/TC4 joints. J Manuf Process 45:1–8. https://doi.org/10.1016/j.jmapro.2019.05.028

Su JH, Tan CW, Wu ZL, Wu LJ, Gong XT, Chen B, Song XG, Feng JC (2020) Influence of defocus distance on laser joining of CFRP to titanium alloy. Opt Laser Technol 124:106006. https://doi.org/10.1016/j.optlastec.2019.106006

Feng ZW, Ma GL, Su JH, Tan CW, Han XH, Zhao HY, Chen B, Song XG (2021) Influence of process parameters on the joint characteristics during laser joining of aluminium alloy and CFRTP. J Manuf Process 64:1493–1506. https://doi.org/10.1016/j.jmapro.2021.03.006

Ashong AN, Lee YS, Park KS, Lee M, Kim JH (2021) Effect of HF treatment on the bonding strength of laser-bonded Mg alloy/carbon fiber-reinforced plastic joint: XPS and NEXAFS study. Appl Surf Sci 556:149782. https://doi.org/10.1016/j.apsusc.2021.149782

Ye YY, Zou Q, Xiao YN, Jiao JK, Du BN, Liu YZ, Sheng LY (2021) Effect of interface pretreatment of Al alloy on bonding strength of the laser joined Al/CFRTP butt joint. Micromachines 12(2):179. https://doi.org/10.3390/mi12020179

Hussein FI, Salloomi KN, Akman E, Hajim KI, Demir A (2017) Finite element thermal analysis for PMMA/st.st.304 laser direct joining. Opt Laser Technol 87:64–71. https://doi.org/10.1016/j.optlastec.2016.07.017

Jiao JK, Wang Q, Wang FY, Zan SP, Zhang WW (2017) Numerical and experimental investigation on joining CFRTP and stainless steel using fiber lasers. J Mater Process Technol 240:362–369. https://doi.org/10.1016/j.jmatprotec.2016.10.013

Jiao JK, Xu ZF, Wang Q, Zan SP, Zhang WW (2018) Research on carbon fiber reinforced thermal polymer/stainless steel laser direct joining. J Laser Appl 30(3):032419. https://doi.org/10.2351/1.5040627

Wang D, Xu JJ, Huang T, Jing RM, Zhang JQ, Xiao RS (2021) Effect of beam shaping on laser joining of CFRP and Al-Li alloy. Opt Laser Technol 143

Taki K, Nakamura S, Takayama T, Nemoto A, Ito H (2016) Direct joining of a laser-ablated metal surface and polymers by precise injection molding. Microsyst Technol 22(1):31–38. https://doi.org/10.1007/s00542-015-2640-2

Rodríguez-Vidal E, Sanz C, Lambarri J, Quintana I (2018) Experimental investigation into metal micro-patterning by laser on polymer-metal hybrid joining. Opt Laser Technol 104:73–82. https://doi.org/10.1016/j.optlastec.2018.02.003

Tan CW, Su JH, Feng ZW, Liu YF, Chen B, Song XG (2021) Laser joining of CFRTP to titanium alloy via laser surface texturing. Chin J Aeronaut 34(5):103–114. https://doi.org/10.1016/j.cja.2020.08.017

Liu YF, Su JH, Ma GL, Han XH, Tan CW, Wu LJ, Chen B, Song XG (2021) Effect of the laser texturing width on hot-pressing joining of AZ31B and CFRTP. Opt Laser Technol 143:107350. https://doi.org/10.1016/j.optlastec.2021.107350

Fetzer F, Sommer M, Weber R, Weberpals JP, Graf T (2018) Reduction of pores by means of laser beam oscillation during remote welding of AlMgSi. Opt Lasers Eng 108:68–77. https://doi.org/10.1016/j.optlaseng.2018.04.012

Jiao JK, Ye YY, Jia SH, Xu ZF, Ouyang WT, Zhang WW (2020) CFRTP -Al alloy laser assisted joining with a high speed rotational welding technology. Opt Laser Technol 127:106187. https://doi.org/10.1016/j.optlastec.2020.106187

Bu HC, Li Y, Yang HY, Wang LL, Zhan XH (2020) Investigation of laser joining process of CFRTP and aluminum alloy. Mater Manuf Process 35(11):1251–1258. https://doi.org/10.1080/10426914.2020.1762205

Wang FY, Zhang PZ, Bu HC, Chen WW, Li BB, Zhan XH (2022) Effect of clamping pressure on interfacial fusion morphology and fracture mechanism of CFRTP/Ti6Al4V laser bonding joint featuring blind hole surface microtextures. Opt Laser Technol 153:108192. https://doi.org/10.1016/j.optlastec.2022.108192

Author information

Authors and Affiliations

Contributions

The welding experiment was conducted by WC and FW. The grinding and polishing of metallographic samples were completed by HB and JL. Data processing and manuscript preparation were led by WC with contributions from all authors.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All authors have read and agreed to the published version of the manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, W., Liu, X., Bu, H. et al. Effect of scanning mode on temperature field and interface morphology of laser joining between CFRTP and TC4 titanium alloy. Int J Adv Manuf Technol 123, 2057–2072 (2022). https://doi.org/10.1007/s00170-022-10084-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10084-8